Fabric preparation and printing and dyeing methods

A fabric and dyeing vat technology, applied in the field of textile printing and dyeing, can solve the problems of difficult automatic shedding of pigments, poor dehydration effect of fabrics, easy breeding of bacteria, etc., and achieves the effects of less residue, improved immunity, and improved blood microcirculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

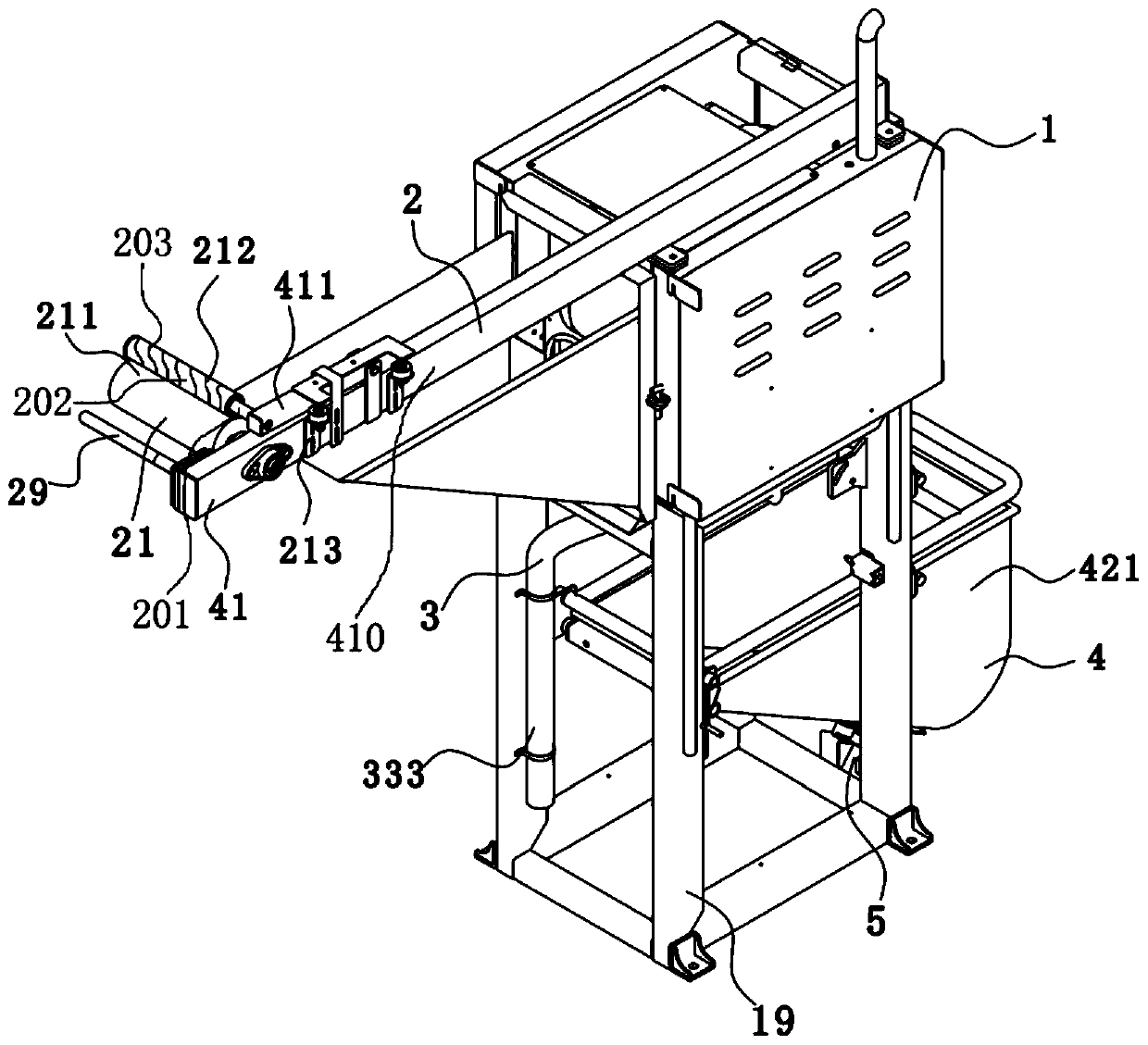

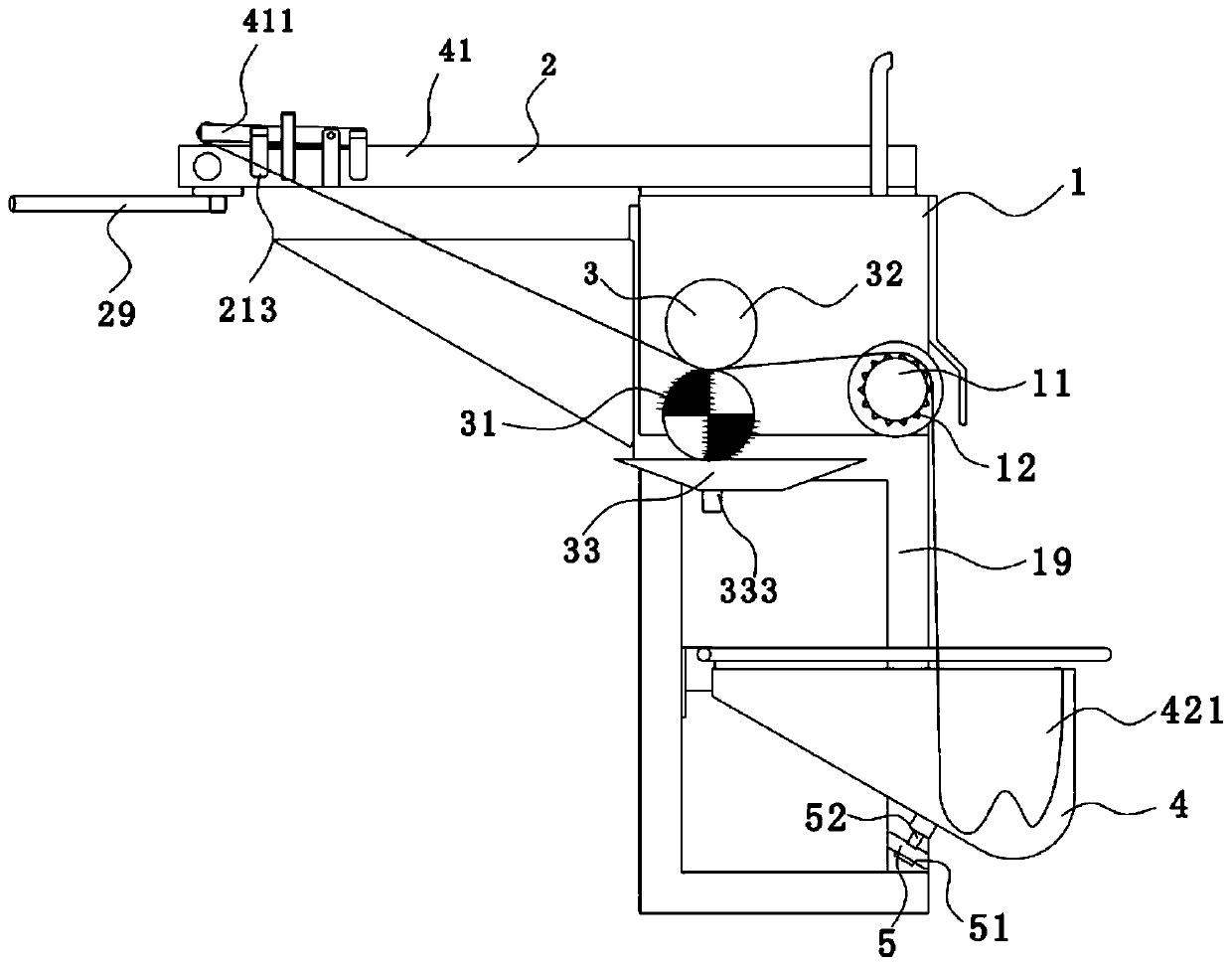

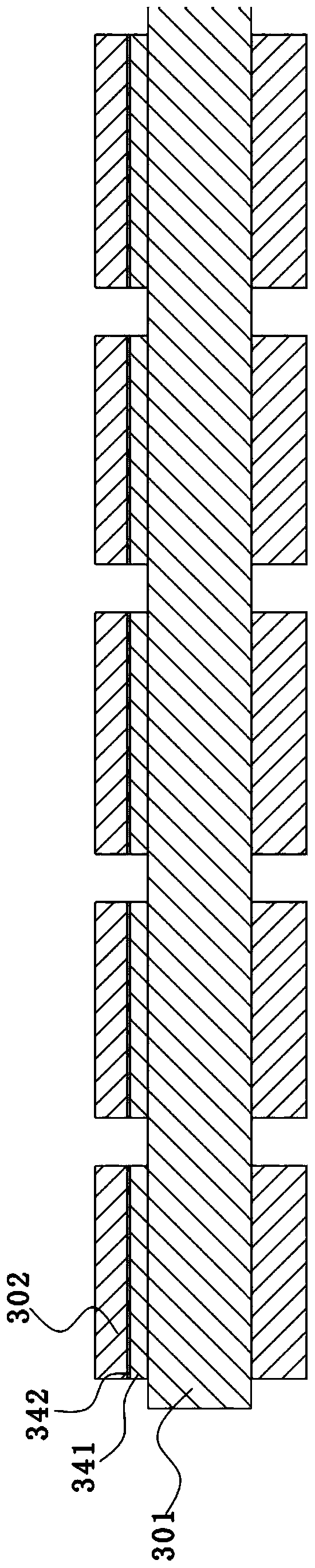

Image

Examples

Embodiment 1

[0027] A method for preparing and dyeing cloth, comprising the steps of:

[0028] The first step: the preparation of the fabric, and the calculation of the mass and parts; select 50 parts of Artemisia argyi, 68 parts of Wulacao and 54 parts of calamus and boil them in boiling water, and then put them into lime water at a temperature of 50 °C after boiling in boiling water Soak for 30 minutes; take it out and rinse it with clean water, soak it in 1% hydrogen peroxide for 40 minutes after rinsing, keep the temperature of the hydrogen peroxide at 50°C during the soaking, and then get parts of mugwort fiber, uraca fiber and calamus fiber;

[0029] Select 9 parts of mugwort fiber, 23 parts of Uralia fiber, and 18 parts of calamus fiber and twist them into moxa fiber strips, Uralia grass fiber strips, and calamus fiber strips with a rubbing machine, and then make the moxa fiber strips, Ula grass fiber strips, and calamus fiber strips Form the blended yarn material together with the ...

Embodiment 2

[0041] A method for preparing and dyeing cloth, comprising the steps of:

[0042] The first step: the preparation of the fabric, calculate the mass and parts; select 20 parts of Artemisia argyi, 42 parts of Wula grass and 30 parts of calamus and boil them in boiling water respectively, and put them into lime water at a temperature of 40 ℃ after boiling in boiling water Soak for 20 minutes; take it out and rinse it with clean water, soak it with 1% hydrogen peroxide for 30 minutes after the rinse is completed, keep the temperature of the hydrogen peroxide at 40°C during the soaking, and then get parts of mugwort fiber, uraca fiber and calamus fiber;

[0043] Use 5 parts of mugwort fiber, 12 parts of Ula grass fiber, and 10 parts of calamus fiber to twist into moxa fiber strips, Ula grass fiber strips, and calamus fiber strips with a rubbing machine, and then make the moxa fiber strips, Ula grass fiber strips, and calamus fiber strips. The sliver and the cotton fiber sliver form...

Embodiment 3

[0049] A method for preparing and dyeing cloth, comprising the steps of:

[0050] The first step: the preparation of the fabric, and the calculation of the mass and parts; choose 30 parts of Artemisia argyi, 55 parts of Wu Lacao and 44 parts of calamus and boil them in boiling water respectively. After boiling in boiling water, put them into lime water at a temperature of 42 °C Soak for 28 minutes; take it out and rinse it with clean water, soak it in 1% hydrogen peroxide for 35 minutes after rinsing, keep the temperature of the hydrogen peroxide at 45°C during the soaking, and then get parts of mugwort fiber, ulagrass fiber and calamus fiber;

[0051] Use 7 parts of mugwort fiber, 18 parts of Ula grass fiber, and 13 parts of calamus fiber to twist into moxa fiber strips, Ura grass fiber strips, and calamus fiber strips with a rubbing machine, and then make the moxa fiber strips, Ula grass fiber strips, and calamus fibers The sliver and the cotton fiber sliver form a blended y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com