28 DEG C liquid and preparation method thereof

A liquid and raw material technology, applied in the field of 28 ℃ liquid and its preparation, can solve the problems of waste of resources and environmental pollution, and achieve the effect of large latent heat, stable performance, fast and sensitive adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

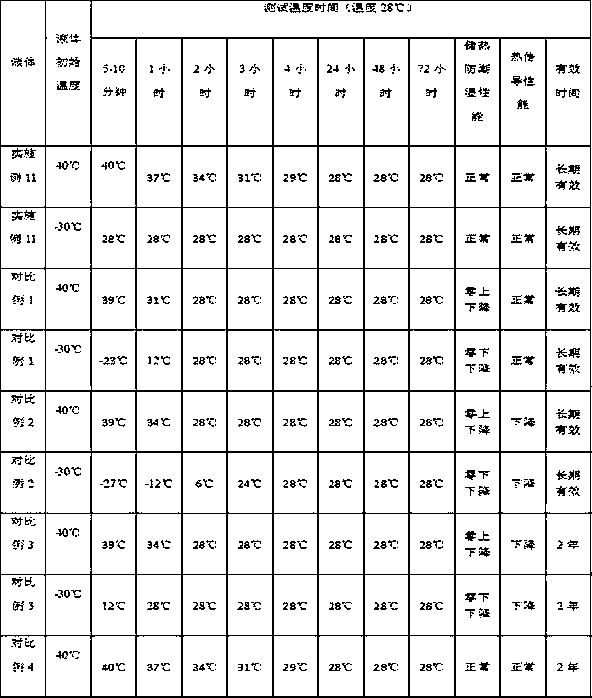

Examples

preparation example Construction

[0037] For the preparation method of the above-mentioned 28°C liquid, the specific steps are as follows:

[0038] (1) Add glacier stone and 40-60% tourmaline into the turning kettle;

[0039] (2) Add water to the turning kettle, heat to 80-150°C, and maintain for 40-80 minutes to fully dissolve the solid;

[0040](3) After the fully dissolved solution has dropped to room temperature, add plant activated carbon, volcanic ash, 60% Uralia volatile oil, calamine, strontium peroxide and strontium in sequence, stir well, place it for 8-15 hours, and heat Stir fully again at 40°C, place for 8-15 hours, heat to 60°C and stir again, place for 40-60 hours to completely dissolve the added raw materials;

[0041] (4) Heat the liquid obtained in step (3) to 20-46°C, filter, then add the remaining uradica volatile oil, remaining tourmaline and graphite, stir well, and place it for 40-60 hours to obtain a 28°C liquid.

[0042] The turning kettle in the step (1) is a stainless steel turning...

Embodiment 1

[0044] A liquid at 28°C, made of the following raw materials in parts by weight: 0.5 parts of graphite, 5 parts of glacier stone, 5 parts of tourmaline, 5 parts of plant activated carbon, 15 parts of volcanic ash, 20 parts of uradica volatile oil, and 8 parts of calamine , 0.1 parts of strontium peroxide, 0.02 parts of strontium, and 80 parts of water.

[0045] For the preparation method of the above-mentioned 28°C liquid, the specific steps are as follows:

[0046] (1) Add glacier stone and 40% tourmaline into the turning kettle;

[0047] (2) Add water to the tumbler, heat to 80°C, and maintain for 40 minutes to fully dissolve the solid;

[0048] (3) After the fully dissolved solution is lowered to room temperature, add plant activated carbon, volcanic ash, 60% volatile oil, calamine, strontium peroxide and strontium in sequence, stir well, place it for 8 hours, and heat to 40 Stir fully again at ℃, let stand for 8 hours, heat to 60°C and stir fully again, let stand for 40 ...

Embodiment 2

[0052] A liquid at 28°C, made of the following raw materials in parts by weight: 0.6 parts of graphite, 5.5 parts of glacier stone, 5.5 parts of tourmaline, 5.5 parts of plant activated carbon, 16 parts of volcanic ash, 21 parts of Uralia volatile oil, and 9 parts of calamine , 0.2 parts of strontium peroxide, 0.05 parts of strontium, and 85 parts of water.

[0053] For the preparation method of the above-mentioned 28°C liquid, the specific steps are as follows:

[0054] (1) Add glacier stone and 42% tourmaline to the turning kettle;

[0055] (2) Add water to the tumbler, heat to 85°C, and maintain for 45 minutes to fully dissolve the solid;

[0056] (3) After the fully dissolved solution is lowered to room temperature, add plant activated carbon, volcanic ash, 60% Uralia volatile oil, calamine, strontium peroxide and strontium in sequence, stir well, place for 9 hours, and heat to 40 Stir fully again at ℃, stand for 9 hours, heat to 60°C and stir fully again, and stand for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com