Method for drawing and modifying wool fibre

A wool fiber modification technology, applied in the field of wool fiber modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

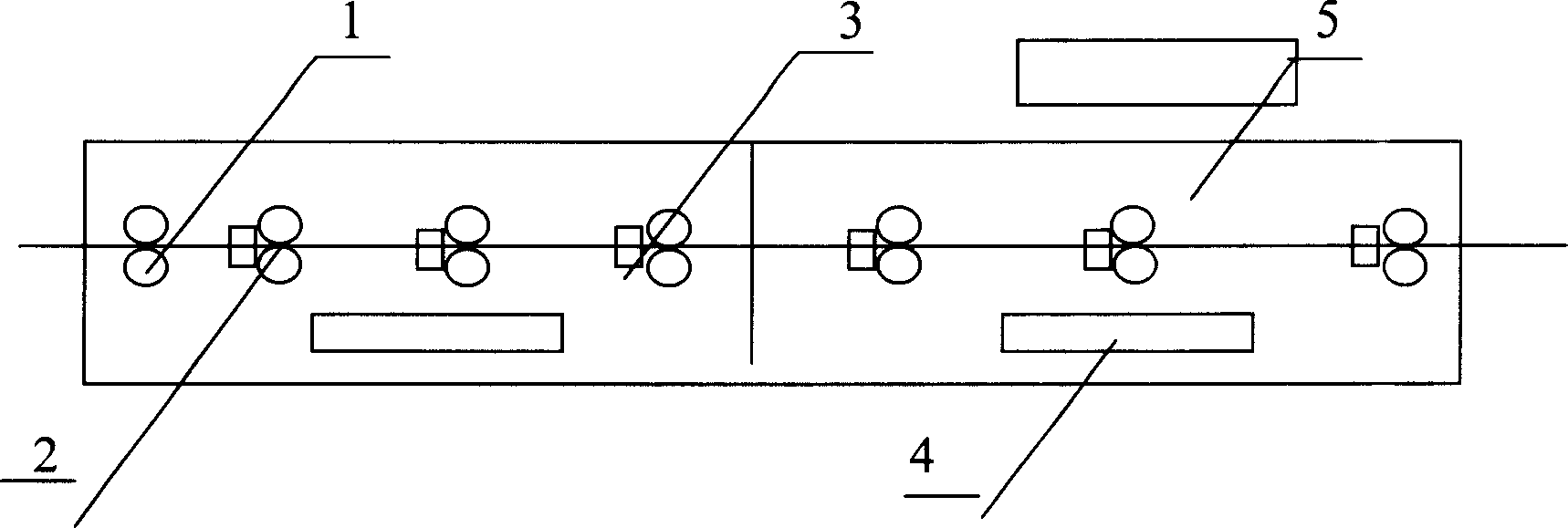

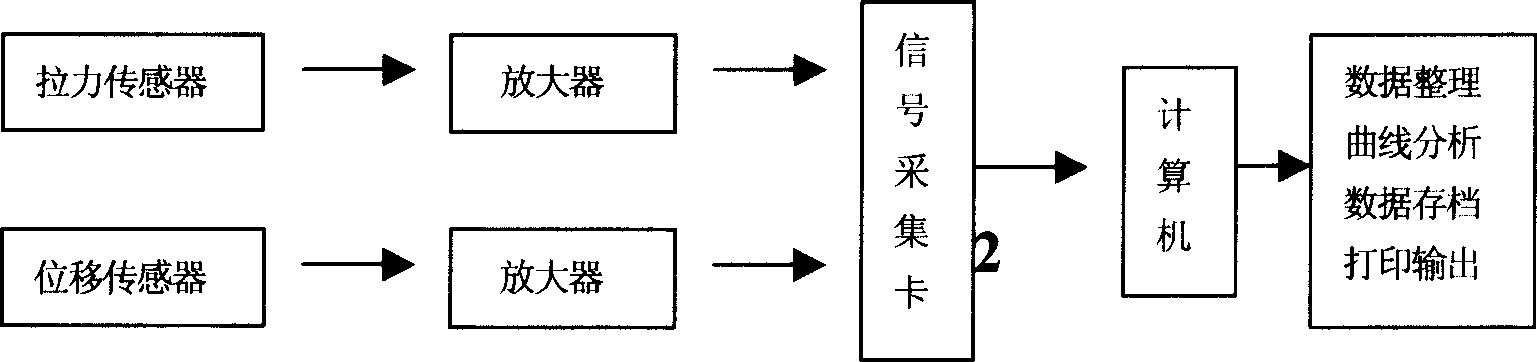

[0092] a. Presoaking solution treatment: wash the wool with clean water, remove impurities, remove the floating skin, and comb it into wool tops; measure the length of the tied wool tops and install them on two chucks; immerse in the stretching pretreatment solution for 20 minutes to fully moisten the wool top fibers wet.

[0093] b. Twisting stretching: Add a certain twist to the wool top and feed it into the false twisting stretching device. The twist of the added false twisting is 1.67 twist / 10cm; the roller gauge is 10mm; the stretching rate is 30%; the stretching speed It is 20mm / min.

[0094] c. Heating and wetting: use steam to heat and wet the twisted top to 80-90°C and start stretching.

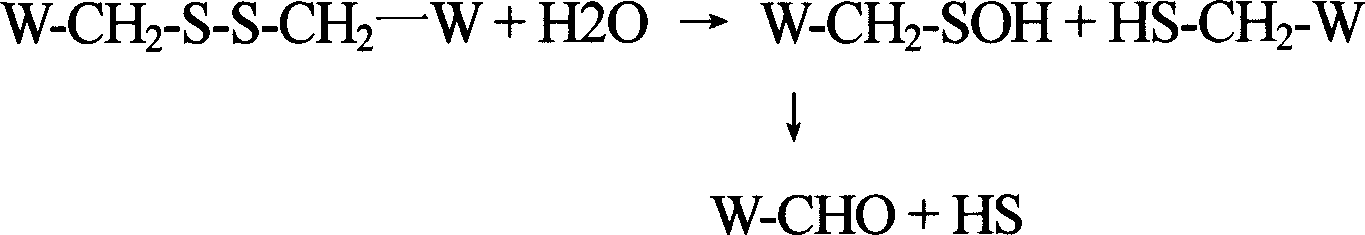

[0095] d. One-time setting: Put the stretched wool top into the first-time setting solution and soak for 3 minutes.

[0096] e. Rinse: Rinse with water for 2 minutes after taking it out.

[0097] f. Secondary setting: After washing, squeeze out the water, then put it into the seco...

Embodiment 2

[0112] a. Presoaking solution treatment: wash the wool with clean water, remove impurities, remove the floating skin, and comb it into wool tops; measure the length of the tied wool tops and install them on two chucks; immerse in the stretching pretreatment solution for 10 minutes to fully moisten the fibers of the wool tops wet;

[0113] b. Twist stretching: add a certain twist to the wool top, and feed it into the false twist stretching device. The twist of the added false twist is 2.0 twist / 10cm, the roller gauge is 8mm, the stretch rate is 35%, and the stretch speed 15mm / min;

[0114] c. Heating and wetting: use steam to heat and wet the twisted top to 80-90°C and start stretching;

[0115] d. One-time setting: put the stretched wool top into the first-time setting solution and soak for 4 minutes;

[0116] e. Rinse: Rinse with water for 2 minutes after taking it out;

[0117] f. Secondary setting: After washing, squeeze out the water, then put it into the secondary sett...

Embodiment 3

[0132] a. Pre-soaking treatment: wash the wool with clean water, remove impurities, remove the floating skin, and comb it into wool tops; measure the length of the tied wool tops and install them on two chucks; immerse in the stretching pretreatment solution for 30 minutes to fully moisten the wool top fibers wet;

[0133] b. Twisting and stretching: Add a certain twist to the wool top and feed it into the false twist stretching device. The twist of the added false twist is 1.2 twist / 10cm, the roller gauge is 12mm, the stretch rate is 25%, and the stretch speed 25mm / min;

[0134] c. Heating and wetting: use steam to heat and wet the twisted top to 80-90°C and start stretching;

[0135] d. One-time setting: put the stretched wool top into the first-time setting solution and soak for 2 minutes;

[0136] e. Rinse: Rinse with water for 2 minutes after taking it out;

[0137] f. Secondary setting: After washing, squeeze out the water, then put it into the secondary setting solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com