Full-automatic ultrasonic lint humidification system

A humidification system and ultrasonic technology, applied in textiles and papermaking, mechanical treatment, fiber treatment, etc., can solve the problems of huge steam humidification facilities, poor atomization degree of high-pressure spray humidification, and unable to keep up with ginning output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

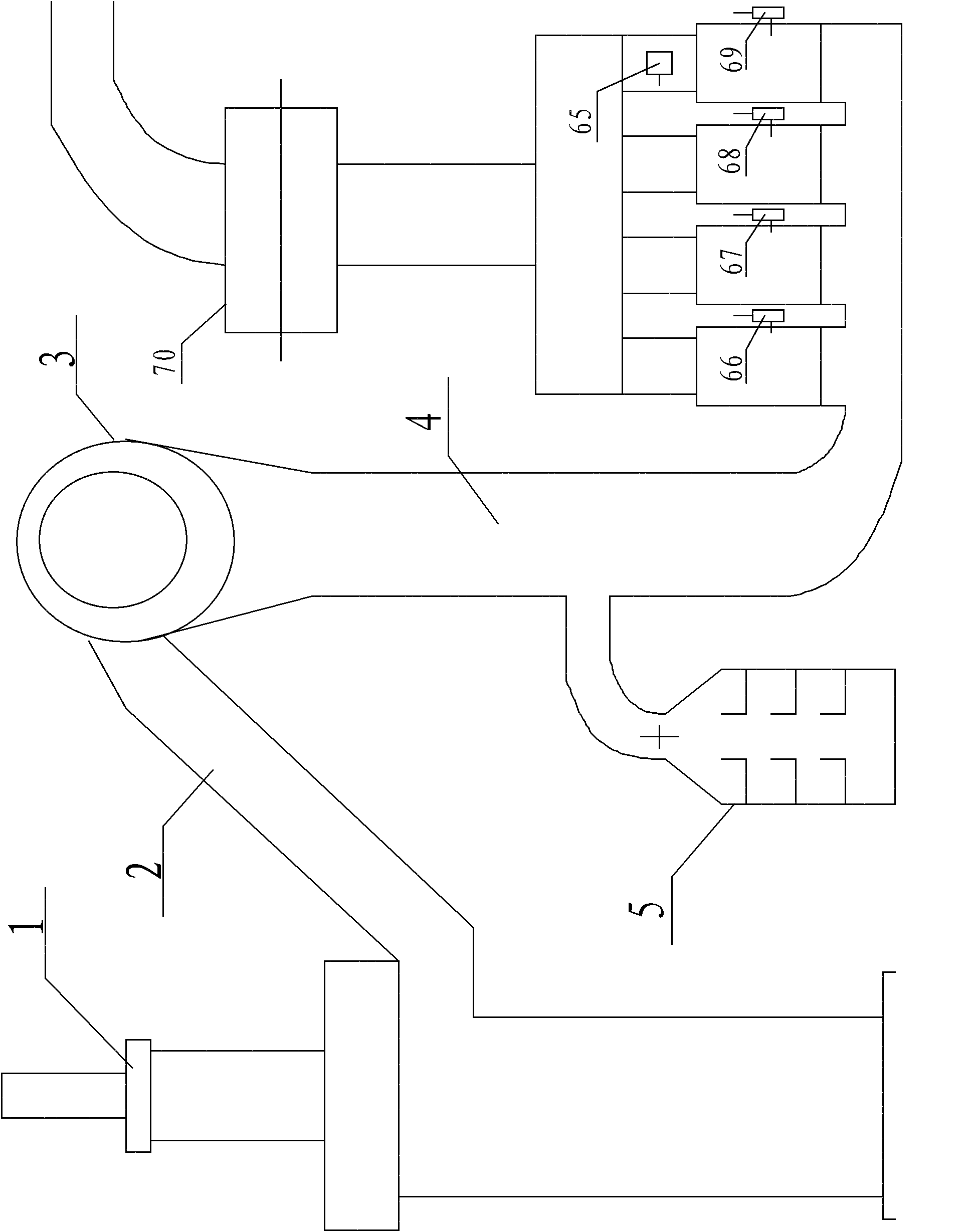

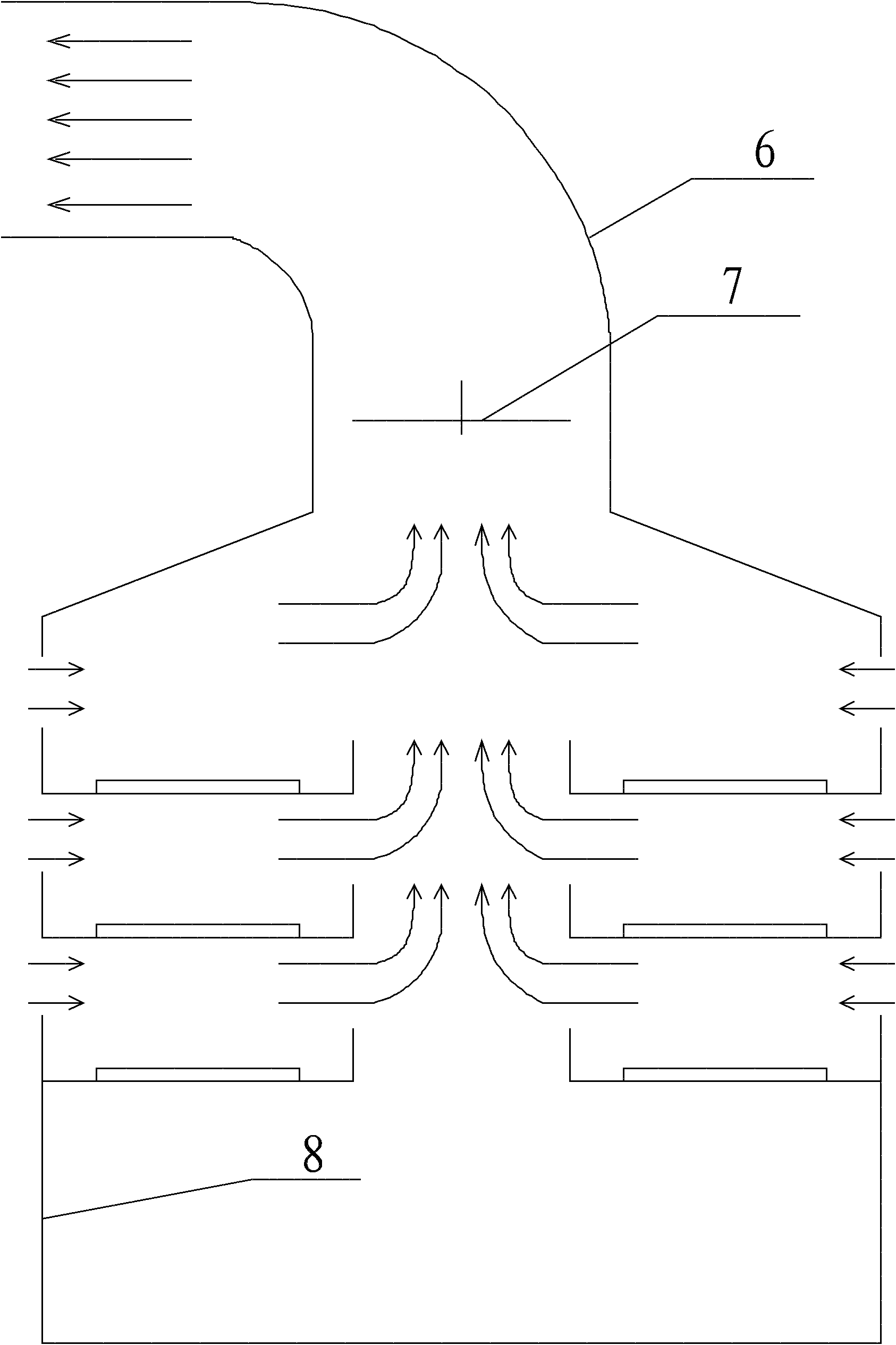

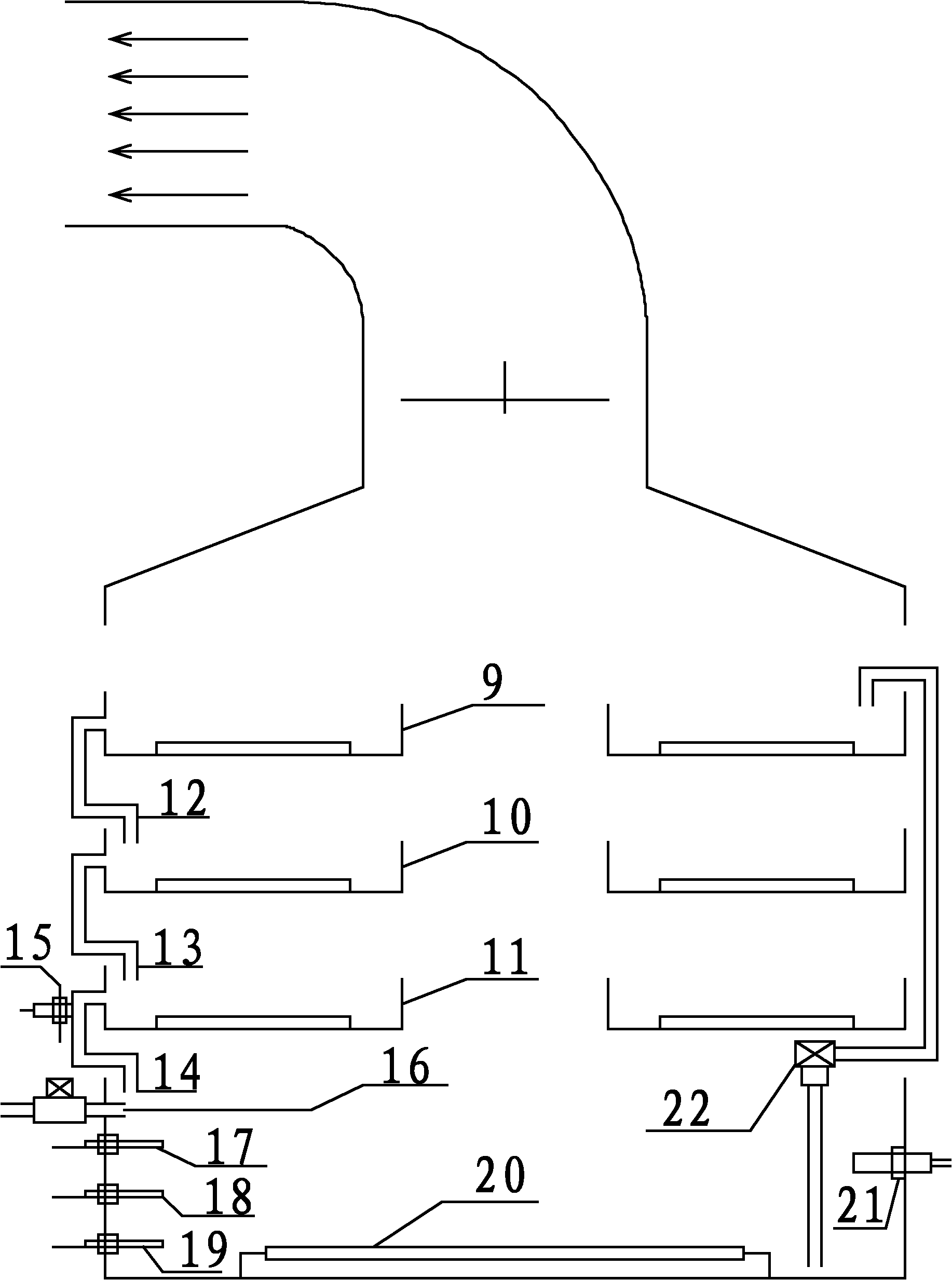

[0027] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

[0028] see figure 1 , figure 2 , image 3 , Pic 4-1 , Figure 4-2 , Figure 5-1 , Figure 5-2 , Figure 6-1 , Figure 6-2 : The present invention has three atomization areas which are respectively composed of an upper layer atomization basin 9, a middle layer atomization basin 10, and a lower layer atomization basin 11. In each atomization basin, 14 evenly divided ultrasonic atomization modules are housed. A mist extraction fan 7 is installed on the top of the humidifier, and a water tank 8 is installed on the bottom. In order to ensure that the water level of each atomization basin is in the best atomization state of the ultrasonic module, an overflow pipe 12 is installed on the outer edge of each atomization basin. , overflow pipe 13, overflow pipe 14, the upper atomization basin overflows to the middle atomization basin, the middle atomizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com