Device for cleaning profile fibers of negative-pressure seed cotton

A technology of cleaning device and negative pressure seeds, applied in fiber processing, mechanical processing, textile and papermaking, etc., can solve the problems of labor, affecting the quality of cotton processing, and poor removal of impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

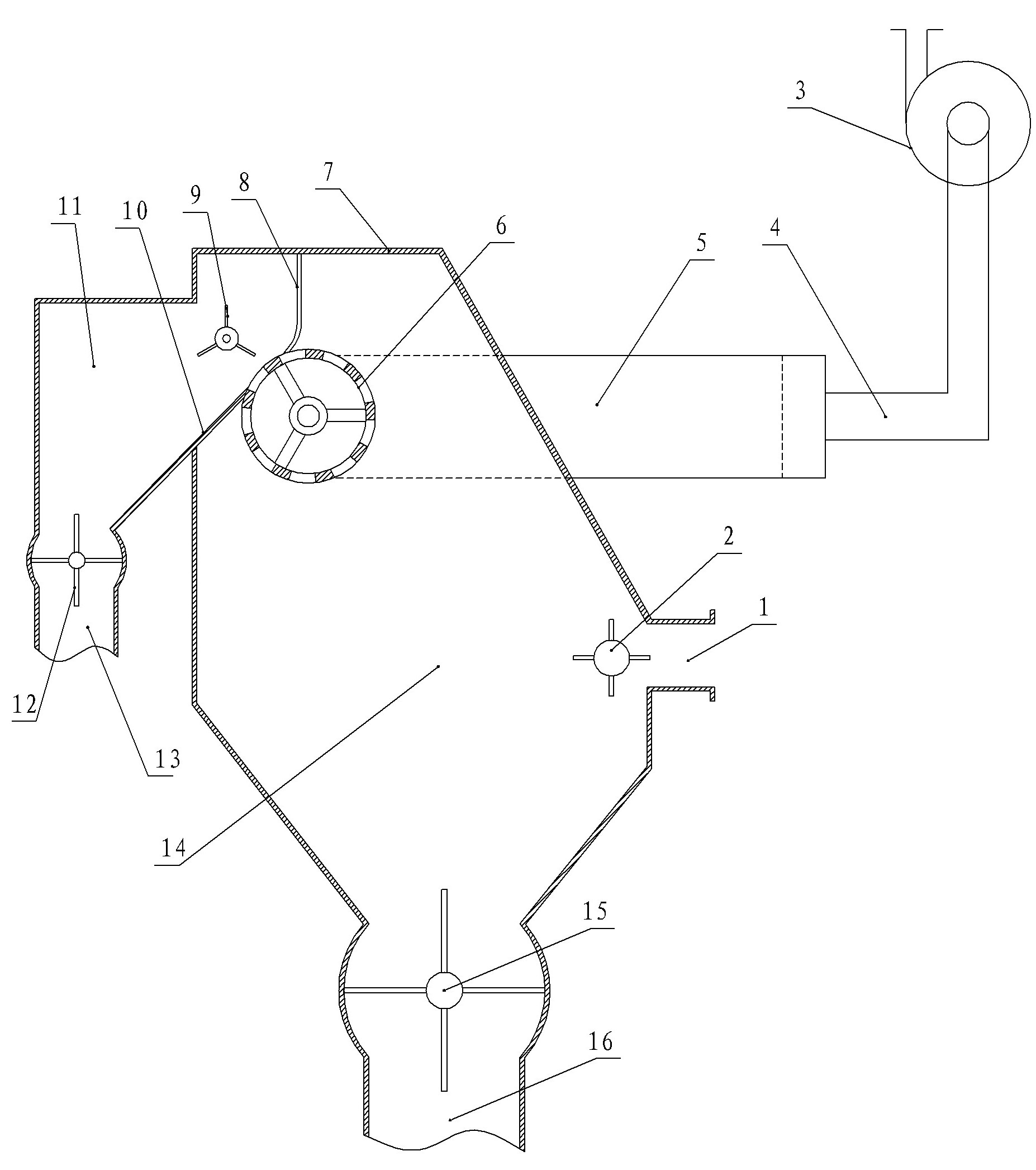

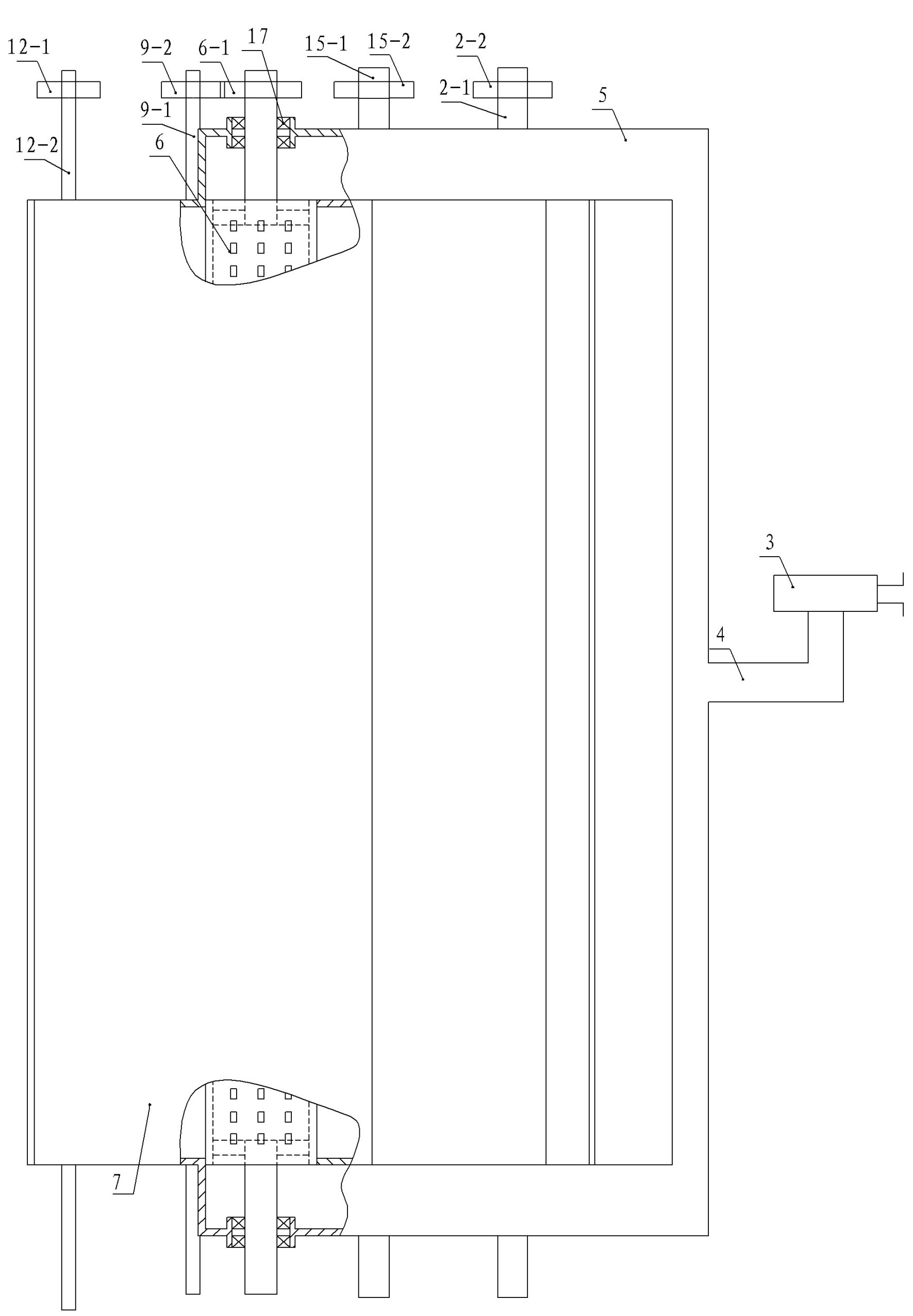

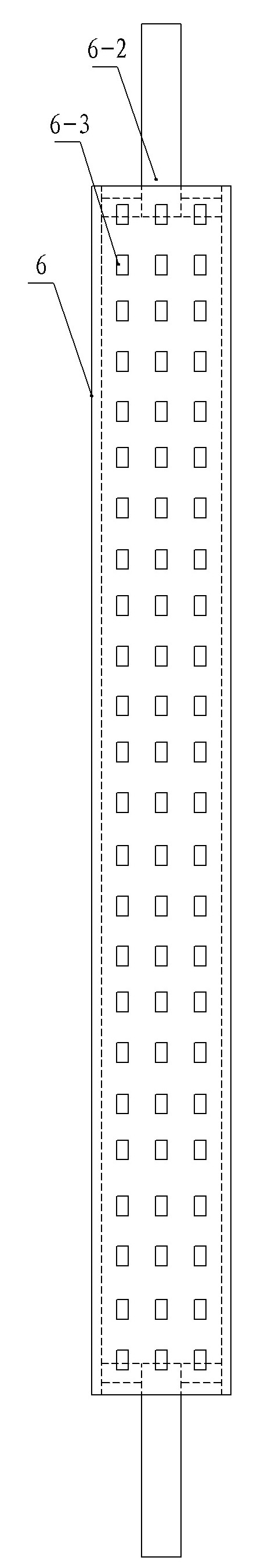

[0023] Example: Figure 1-Figure 4 , a negative pressure seed cotton foreign fiber cleaning device, including a shell, the shell is provided with a material inlet, a material outlet, and a miscellaneous discharge port. The inside of the shell is two parts, one part is the separation area, and the other part is the foreign fiber. fiber collection area; the inlet and outlet are connected to the separation area, and the miscellaneous discharge port is connected to the foreign fiber collection area; The above-mentioned feed port is provided with opening and ejecting rollers; a long-hole dust cage is provided at the position connected with the foreign fiber collection area in the separation area, and the two ends of the long-hole dust cage pass through the shell and are installed through bearings. There is also an air duct connected to its end outside the body, and the end of the air duct is connected to an induced draft fan; the housing is provided with a baffle approximately tang...

Embodiment 2

[0033] Embodiment two: see Figure 1-Figure 2 , Figure 4-Figure 5 , the second embodiment is basically the same as the first embodiment, the similarities will not be repeated, and the difference is, use Figure 5 Slotted dust cage in place of image 3 The long hole dust cage in, that is, the long hole on the long hole dust cage described in embodiment two is a transverse long hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com