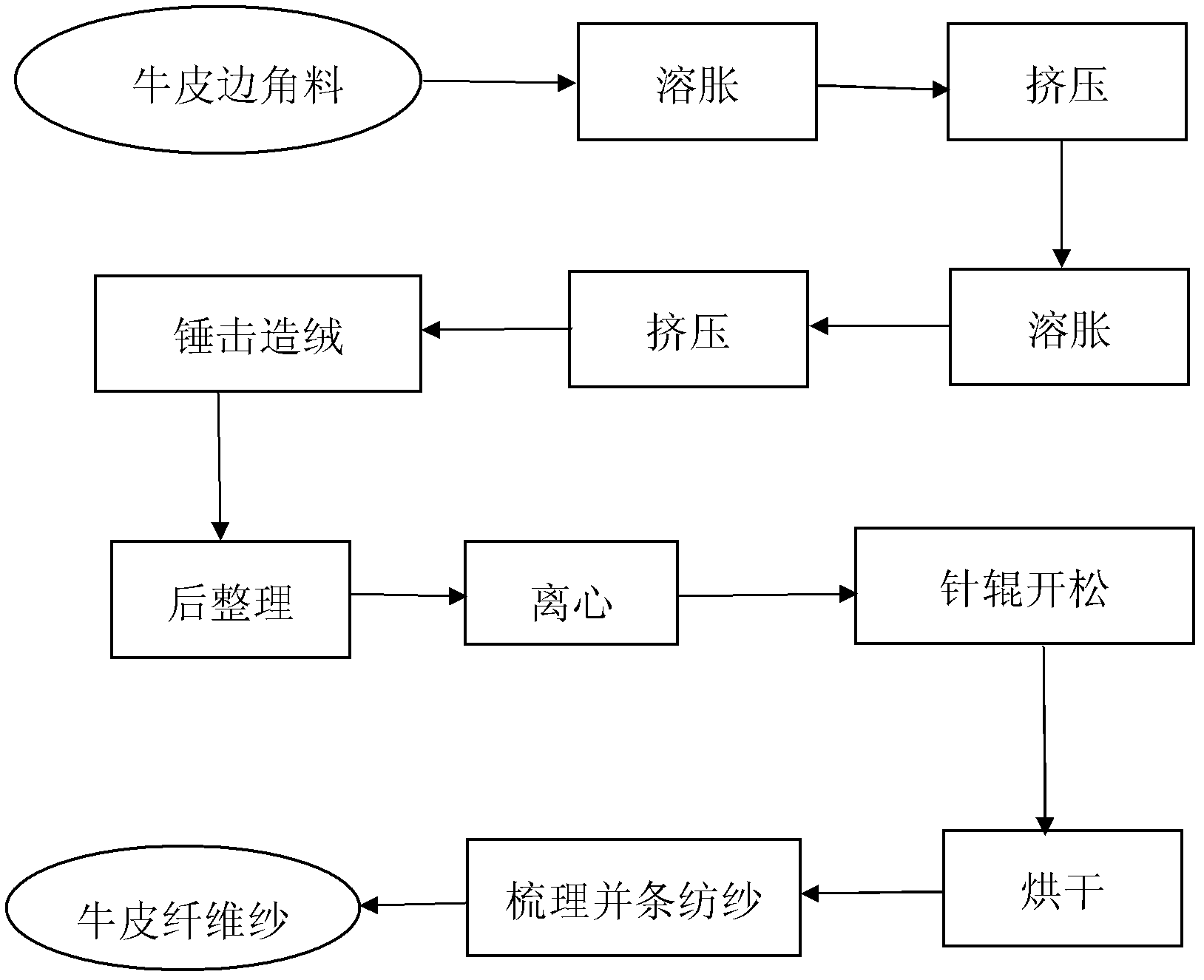

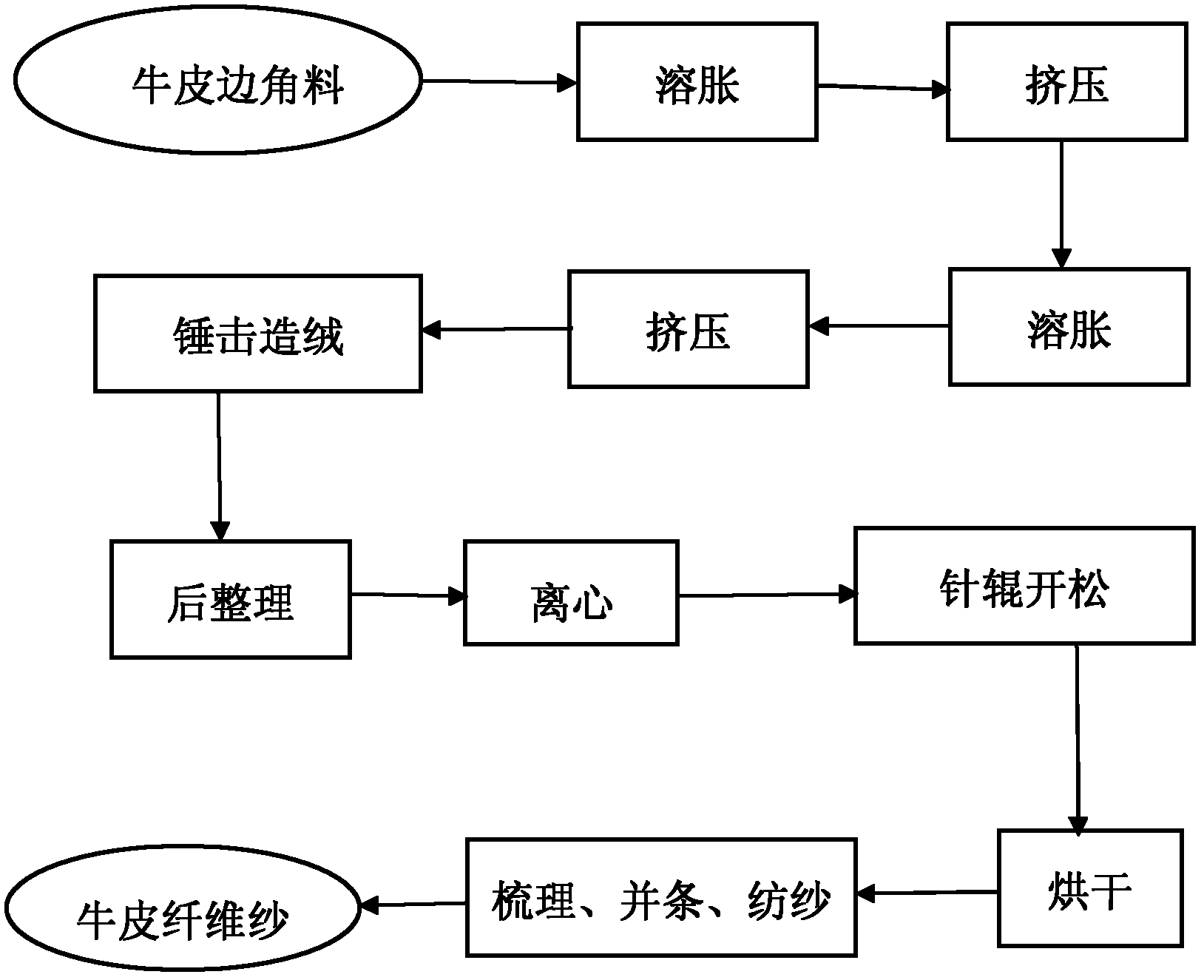

Method for preparing cowhide fiber yarns from cowhide leftover materials

A technology of kraft fiber and leftover materials, applied in the chemical post-treatment of fibers, fiber treatment, yarn, etc., can solve the problems of collagen fiber breaking and affecting the quality of yarn products, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Screen, color-separate, and remove impurities from American cowhide two-layer leather scraps, and put 5KG of American cowhide second-layer leather scraps into a soaking solution for puffing and softening. The soaking solution is to add penetrating agent 8KG, NaOH 1.0 Kg (when 1.0KgNaOH is added, it is made into a NaOH aqueous solution with a concentration of 10g / l, and then added) and 5KG of bulking agent (among them, the penetrating agent is sulfosuccinate sodium salt, and the bulking agent is aromatic hydrocarbon and higher fatty alcohol poly The compound of oxyethylene ether and the compound of phenols and higher fatty alcohol polyoxyethylene ether), the temperature of soaking water is 52°C, and the soaking time is 8 hours. Extruding, wherein the water content of the extruded cowhide leftovers is 25%; repeated soaking and extrusion, wherein the second soaking and swelling time is 8 hours, and the water content of the extruded cowhide leftovers is 25%; The time for so...

Embodiment 2

[0046] Screening, color separation, and impurity removal of China Hebei cowhide second-layer leather scraps, 5KG of China Hebei cowhide second-layer leather scraps are put into soaking liquid for puffing and softening. NaOH 1.5Kg (when 1.5KgNaOH is added, it is made into a NaOH aqueous solution with a concentration of 10g / l, and then added) and 5KG of bulking agent (among them, the penetrating agent is oleoyl amino acid sodium salt, and the bulking agent is polyphenols and higher fatty alcohols) compound of oxyethylene ether), the soaking water temperature is 50°C, and the soaking time is 8 hours, and the second-layer cowhide leftovers after the first expansion and softening are extruded by a hydraulic press, wherein the content of the extruded cowhide leftovers The water content is 25%; soaking and extrusion are repeated, wherein the second soaking and swelling time is 8 hours, and the water content of the cowhide leftovers after extrusion is 25%; the third soaking and swellin...

Embodiment 3

[0048] The American cowhide three-layer cowhide leftovers are screened, color-separated, and impurities are removed, and the American cowhide three-layer cowhide leftovers of 5KG are put into a soaking solution to expand and soften. The soaking solution is to add penetrating agent 8KG, NaOH0. 25Kg (when 0.25KgNaOH is added, it is made into a NaOH aqueous solution with a concentration of 10g / l, and then added) and 5KG of bulking agent (among them, the penetrating agent is straight-chain fatty alcohol polyoxyethylene ether, and the bulking agent is aromatic hydrocarbon and higher fatty alcohol. compound of polyoxyethylene ether), the soaking water temperature is 52°C, and the soaking time is 8 hours, and the first puffed and softened second-layer cowhide leftovers are extruded by a hydraulic press, wherein the extruded cowhide leftovers The water content is 25%; repeated soaking and extrusion, wherein, the second soaking and swelling time is 8 hours, and the water content of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com