Roundness measuring instrument and measuring method thereof

A roundness measuring instrument and roundness error technology, applied in the field of roundness measuring instrument and its measurement, can solve the problems of high environmental temperature requirements, slow detection speed of roundness instrument, high equipment cost, etc., and achieve low environmental requirements, reduce The effect of low detection cost and hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation of the roundness measuring instrument and its measuring method of the present invention will be described in detail below in conjunction with the accompanying drawings.

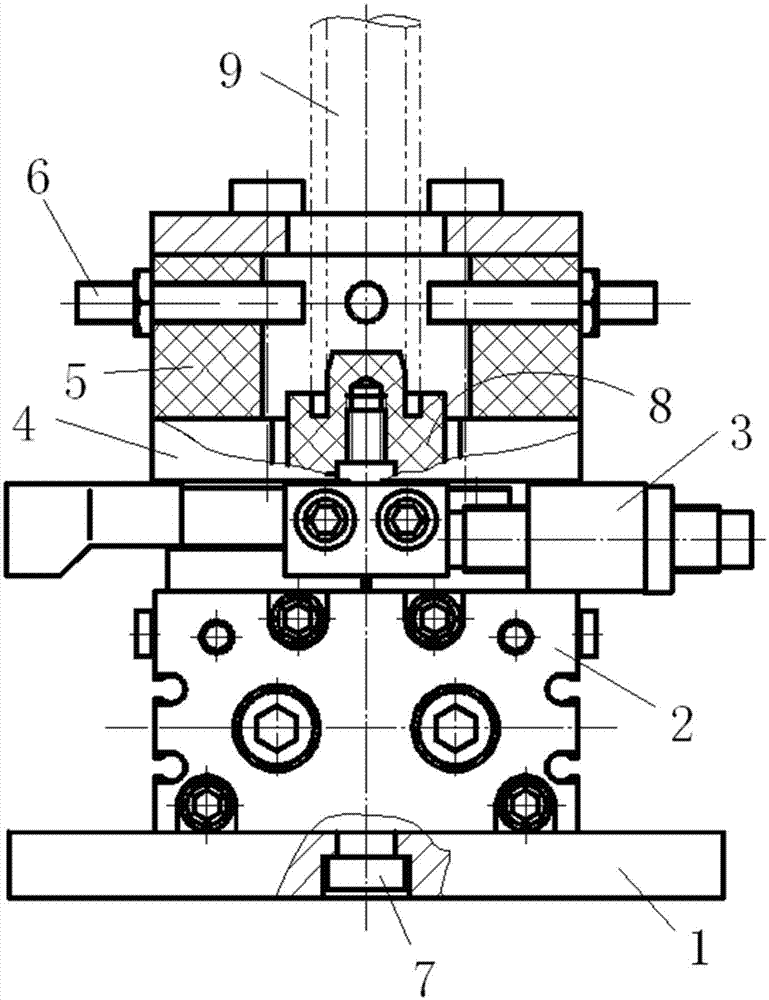

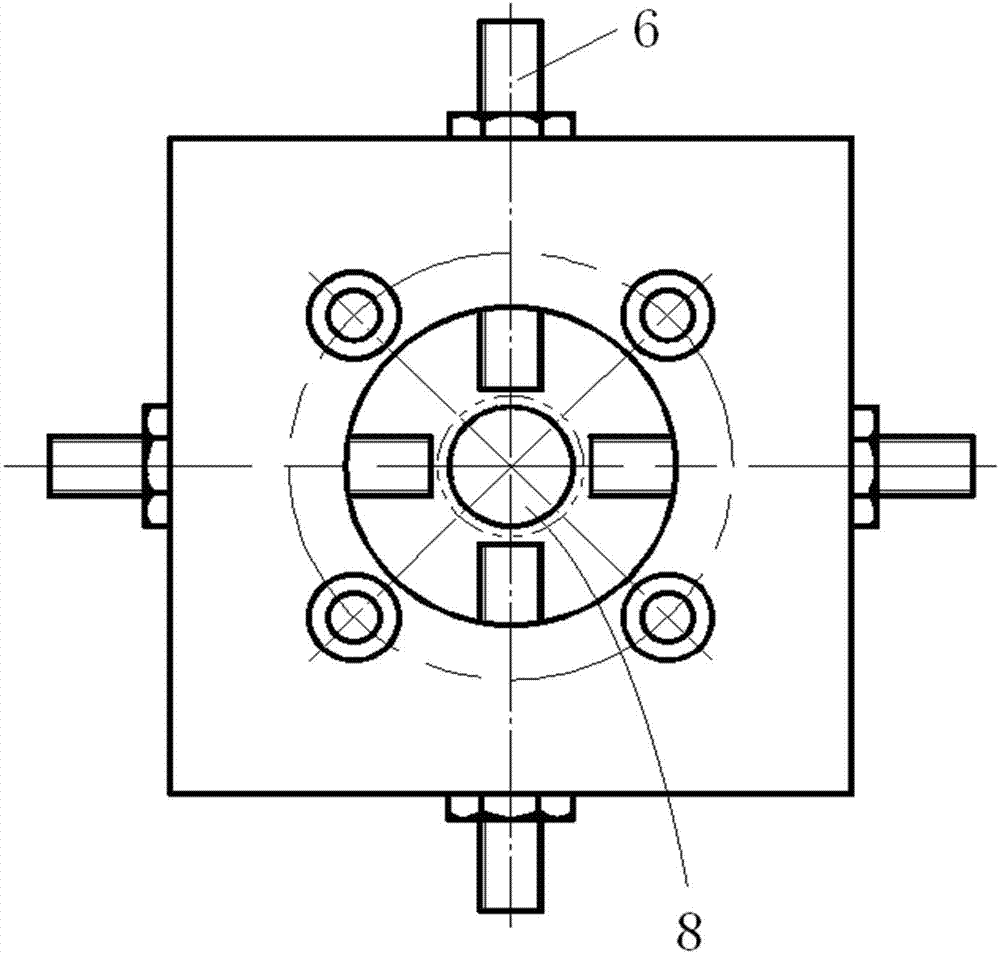

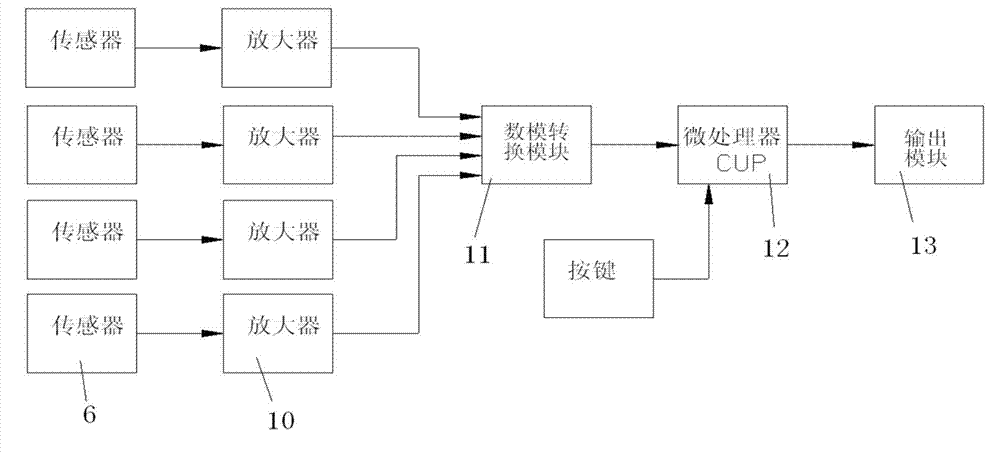

[0045] See attached figure 1 And attached figure 2 , a swing cylinder 2 is fixedly installed on the base 1 of the roundness measuring instrument, and the swing cylinder 2 is controlled by a pneumatic unit to realize rotation and swing. The fixed part of the swing cylinder 2 is fixedly connected with the base 1, and the swing part of the swing cylinder 2 is fixedly connected with a platform3. A sensor bracket 5 is arranged on the platform 3 through the connecting plate 4. The sensor bracket 5 is a hollow structure connected up and down. Four displacement sensors 6 are arranged on the sensor bracket 5. The four displacement sensors 6 are arranged in a cross shape, and the two displacement sensors are arranged in the same position. On a straight line, perpendicular to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com