Electroplating wastewater treatment reclaiming technique

A technology of electroplating wastewater and process, which is applied in the direction of metallurgical wastewater treatment, adsorption water/sewage treatment, neutralization water/sewage treatment, etc. It can solve the problem that the water quality and quantity cannot meet the needs of production, the treatment process is different, and it is difficult to reuse, etc. problems, to achieve the effects of small footprint, lower production costs, and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

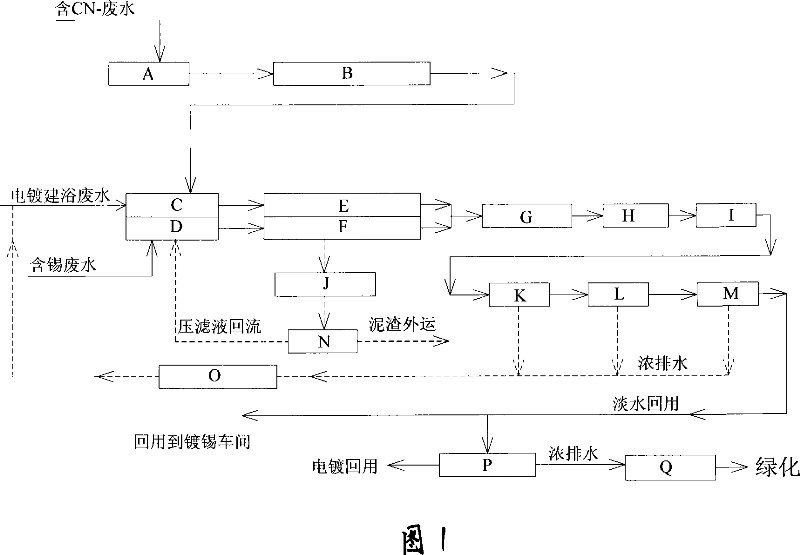

[0041] As shown in Fig. 1, it is a kind of electroplating waste water treatment reuse process of the present invention, adopts following process steps successively:

[0042] 1) Harmless treatment:

[0043] a. Wastewater containing cyanide 10m 3 After passing through the cyanide-containing wastewater regulating pool A, adjust the water quality and quantity, enter the reaction tank B, add sodium hydroxide with a concentration of 10%, the flow rate is 10-17L / H (liter / hour), adjust the pH to 10-11, and then add sodium hypochlorite After oxidation, enter reaction tank B, add hydrochloric acid with a concentration of 10%, flow rate is 4.5-6L / H (liter / hour), adjust pH 8-8.5, add sodium hypochlorite to carry out secondary redox treatment;

[0044] b. After two-stage oxidation treatment, the wastewater or tin-containing wastewater enters the tin-containing wastewater regulating tank D, and enters the heavy metal reaction tank F after homogenizing and equalizing, adding sodium hydroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com