Tubular centrifuge drum and control method

A separator and drum technology, applied in centrifuges and other directions, can solve the problems that the drum cannot be connected to the power supply, air source or other contact control components, cannot install the rotating weight parts, and it is difficult to close its passage, etc., to achieve Save the purchase of equipment, maintain funds, and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

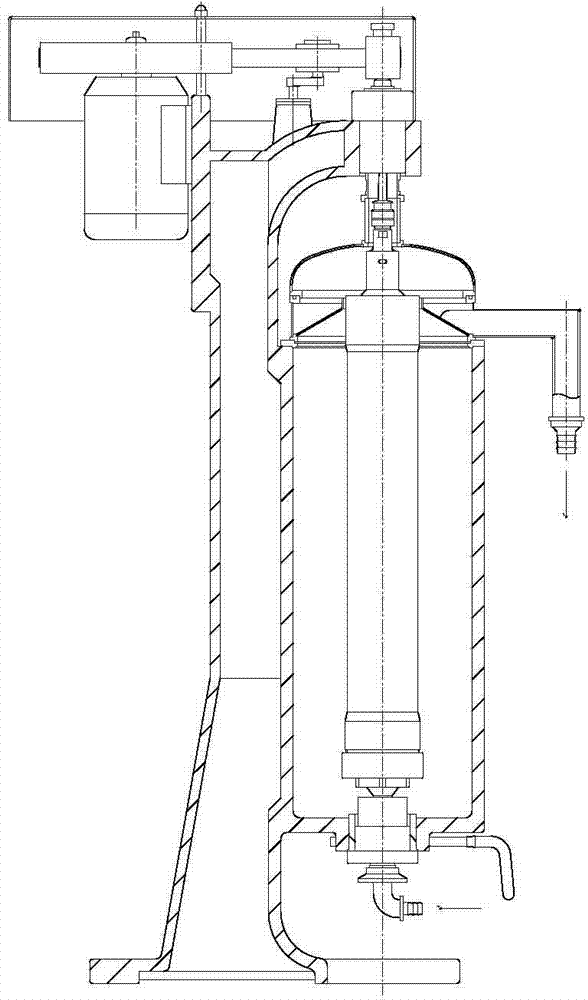

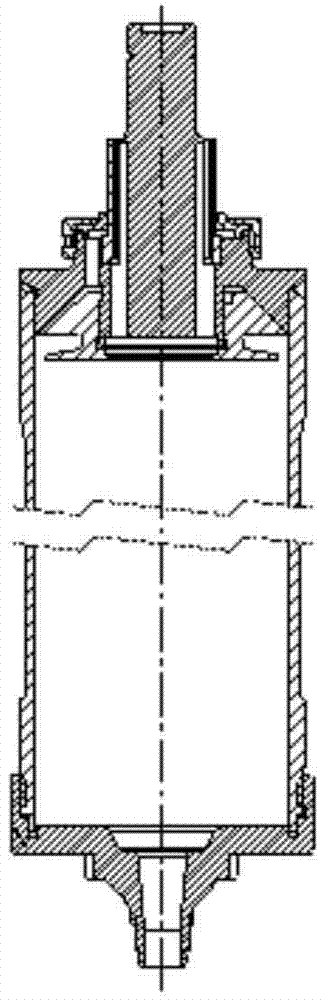

[0054] The tubular separator is a kind of continuous separation and manual slag discharge separation equipment. Due to the limited volume in the cylinder, various devices must be disassembled after the shutdown (see attached figure 1 , Generally, there are locking sleeves, semi-circular sleeves, spindle nuts, liquid pan covers, liquid pans, etc. After the rotor is taken out of the fuselage, the bottom shaft cover is opened to manually clean the sediment in the cylinder. It is an intermittently operated equipment. The drum structure of prior art sees attached figure 2 ; The figure includes a drum 21 and a bottom shaft cover 22 .

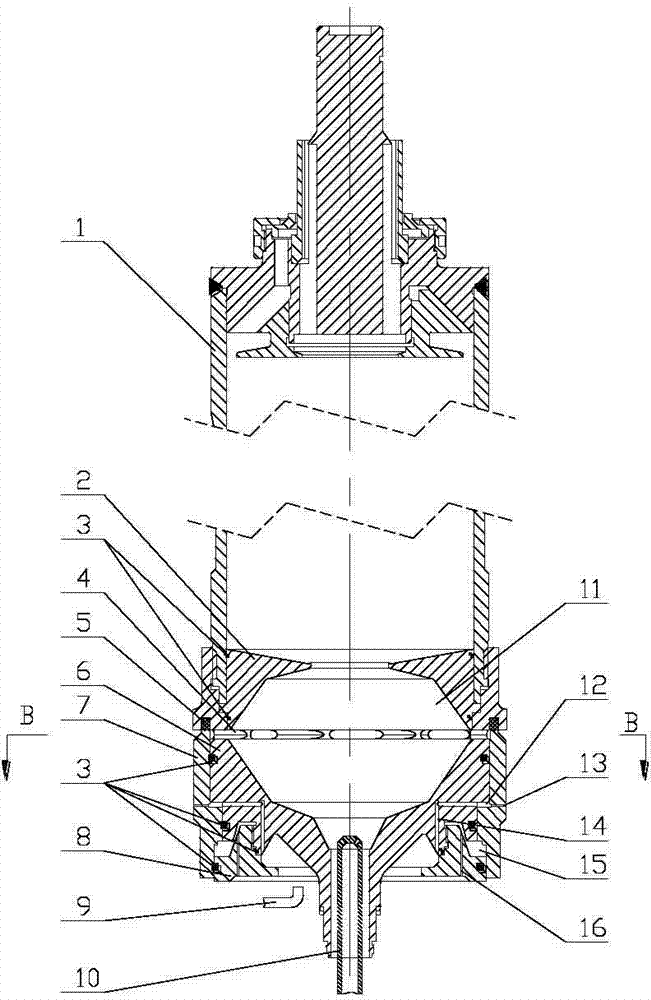

[0055] The present invention has made great improvement on the basis of traditional tubular separator drum (see attached image 3 ), additional hydraulic oil chamber 15, operating water chamber 12 and solid deposition area 11 are added on the original basis. The hydraulic oil chamber 15 has been injected with a certain amount of hydraulic oil in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com