Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

A technology for fermentation waste liquid and compound fertilizer, which is applied in the preparation of organic fertilizer, organic fertilizer, and biological organic part treatment, etc., can solve the problems of large space occupation, long fermentation period, poor biological activity of organic matter, etc., and reduce downtime for maintenance. , the effect is obvious, the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

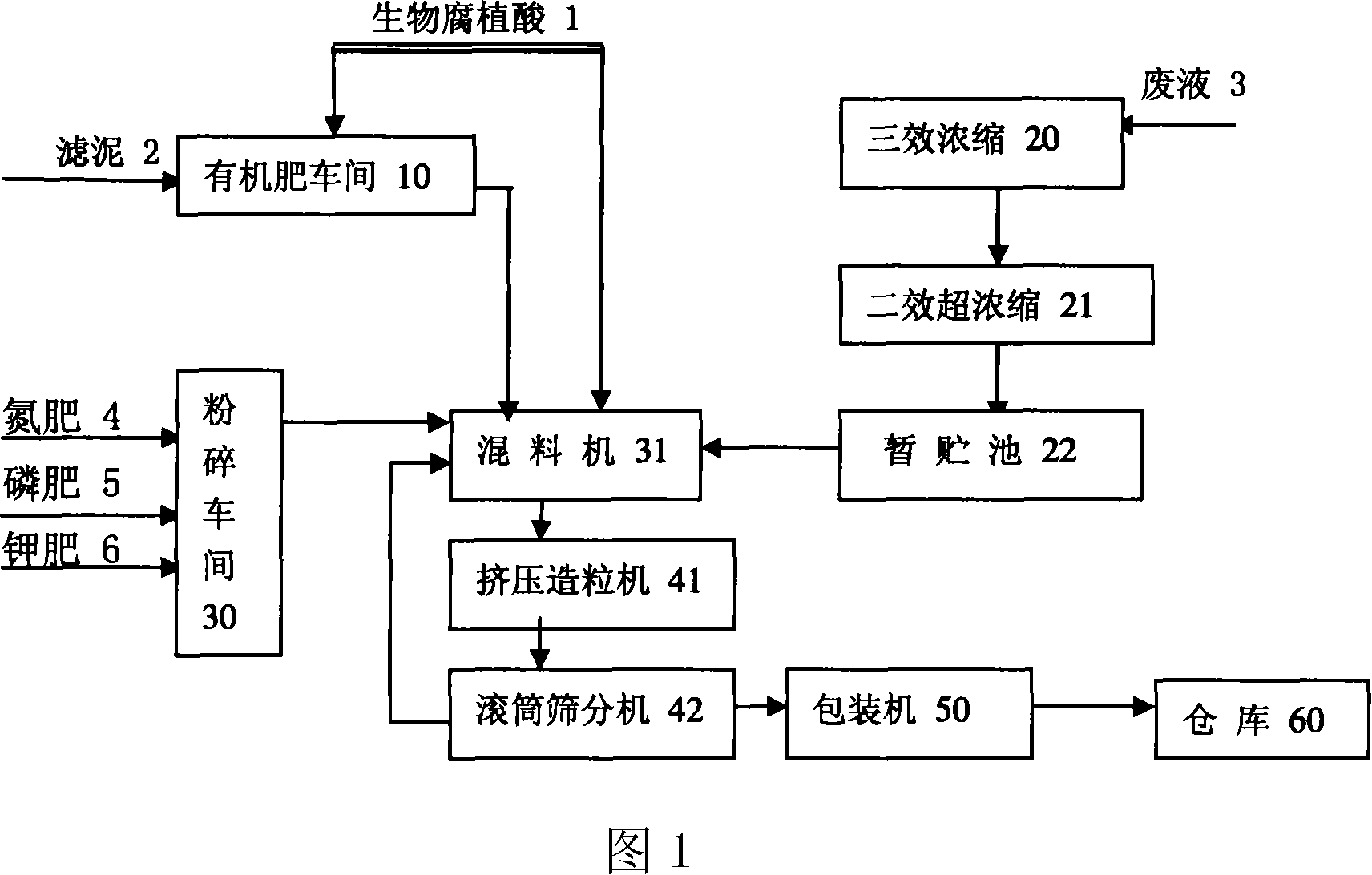

[0021] An embodiment of the present invention is used in an alcohol plant using molasses waste liquid as a raw material. The alcohol plant is designed to operate 100 days a year and discharge 1340 tons of molasses alcohol waste liquid every day. The production process of this embodiment is shown in Figure 1.

[0022] One of the raw materials used in this example—biological humic acid 1—is prepared from bagasse. For its preparation method, please refer to another patented technology of the applicant "aquaculture water quality improver made of bagasse and its preparation method and application" (Patent No. ZL 03138767.5). The water quality improver produced according to the patented technology accounts for 3% to 5% of water by weight and can be used as the biological humic acid 1 of this embodiment. The biological humic acid 1 contains Bacillus subtilis, Bacillus coagulans, high-temperature yeast, lactic acid bacteria and fermenting filamentous bacteria, and is in the form of 8...

Embodiment 2

[0073] The present invention is used in a factory for processing monosodium glutamate with molasses. The factory discharges 1340 tons of waste liquid every day, and operates 100 days a year. The waste liquid that this factory molasses processing monosodium glutamate produces is that main raw material is produced organic-inorganic compound fertilizer, can refer to the production process of embodiment 1 to specify, and correspondingly carry out the operation of following three processes:

[0074] Process one, the biological humic acid made from 65% to 68% of filter mud, 10% to 12% of bagasse powder, 1.5% to 2.5% of wheat bran, 0.4% to 0.6% of bagasse, 16% by weight %~25% of the regulator is stirred and mixed evenly, and the material is transported to the fermentation tank. The height of the material in the fermentation tank is 1.1 to 1.2 meters, and the surface is covered with air-permeable thermal insulation material; the maximum temperature of the material after 7 to 9 days is ...

Embodiment 3

[0117] The present invention is used in a factory that discharges 1340 tons of waste water of molasses processing yeast every day, and the factory produces 100 days a year. The waste liquid produced by the molasses processing yeast in this factory is used as the main raw material to produce organic-inorganic compound fertilizer. The specific instructions of the production process in Example 1 can be referred to, and the following three processes can be carried out correspondingly:

[0118] Process one, the biological humic acid made from 65% to 68% of filter mud, 10% to 12% of bagasse powder, 1.5% to 2.5% of wheat bran, 0.4% to 0.6% of bagasse, 16% by weight %~25% of the regulator is stirred and mixed evenly, and the material is transported to the fermentation tank. The height of the material in the fermentation tank is 1.1 to 1.2 meters, and the surface is covered with air-permeable thermal insulation material; the maximum temperature of the material after 7 to 9 days is 60℃~ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com