Semi-automatic box nailing machine

A semi-automatic technology for box tacking machines, applied in the field of semi-automatic box tacking machines, can solve the problems of limited, uneven, and increased difficulty of carton clamping and pushing, achieving uniformity and controllability, low proficiency requirements, Avoid the effects of gravitational instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

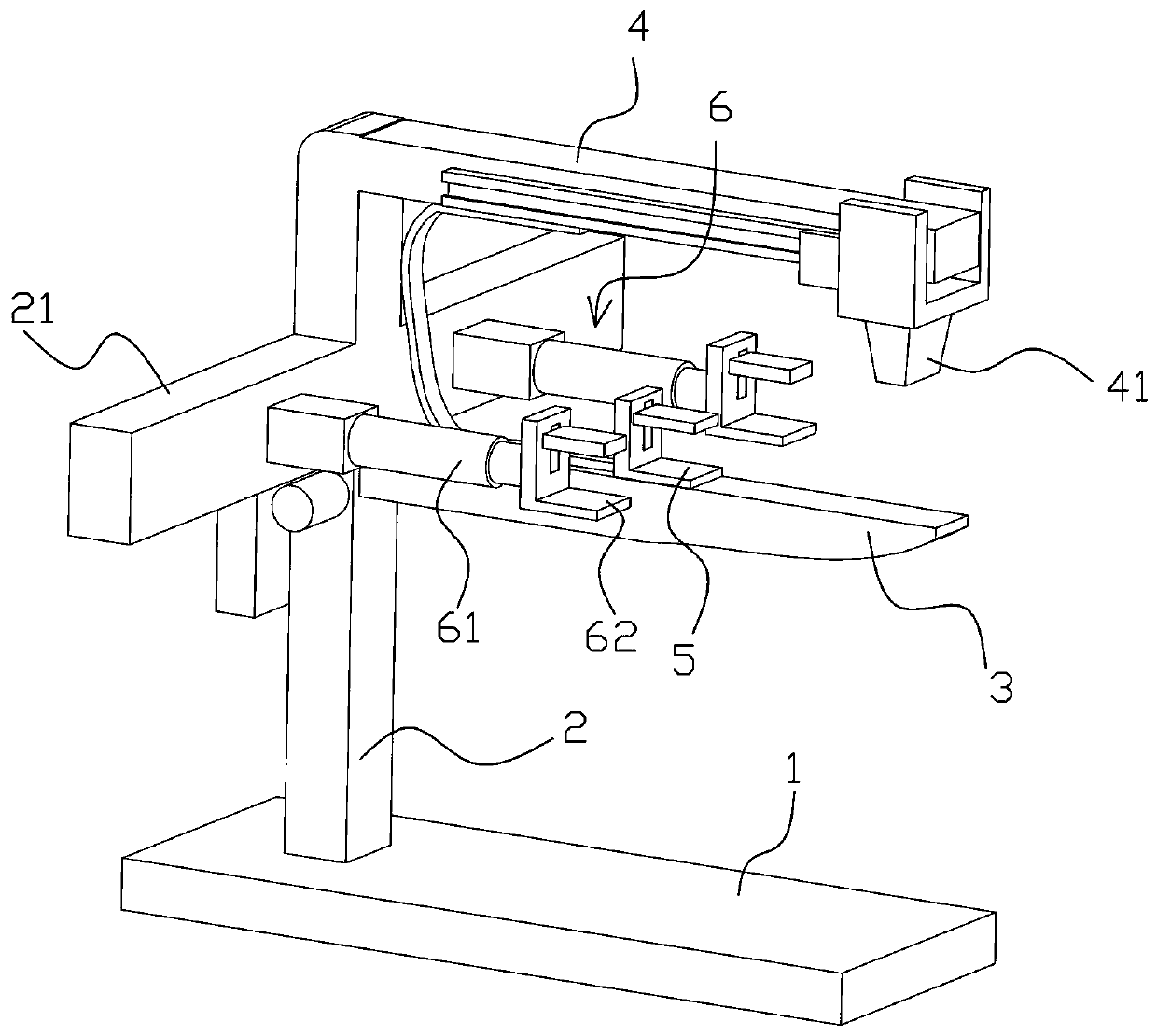

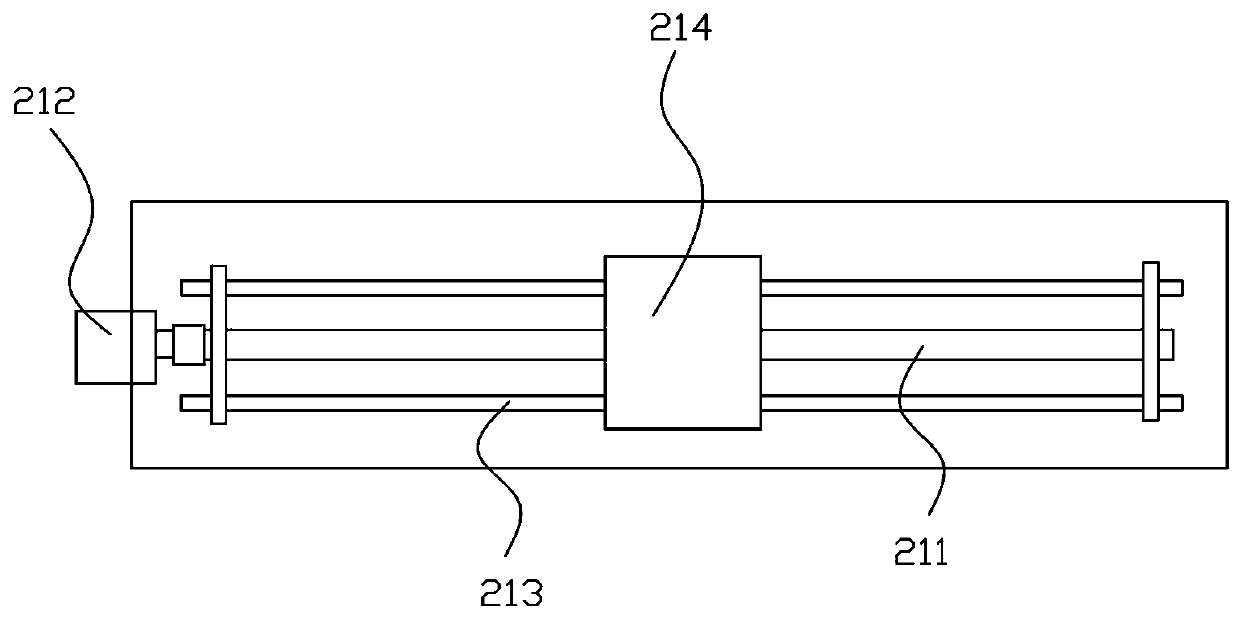

[0029] Such as figure 1 As shown, the present embodiment provides a semi-automatic nail box machine, including a chassis 1, a column 2, a crossbeam 3, a boom 4 and a motor, the end of the boom 4 is provided with a nailing mechanism 41, and the column 2 is provided with a nailing mechanism 41. There is an electric control box for controlling the motor, the electric control box is electrically connected with a foot switch, the beam 3 is provided with a first clamping mechanism 5 that can reciprocate along the extension direction of the beam 3 length, the second The reciprocating motion of a clamping mechanism 5 and the nailing action of the nailing mechanism 41 can be controlled by the same motor, and can also be controlled by different motors. Specifically, after the foot switch is depressed, the electric control box detects a corresponding signal to control the motor. , the nailing mechanism 41 and the first clamping mechanism 5 work; the first clamping mechanism 5 realizes ex...

Embodiment 2

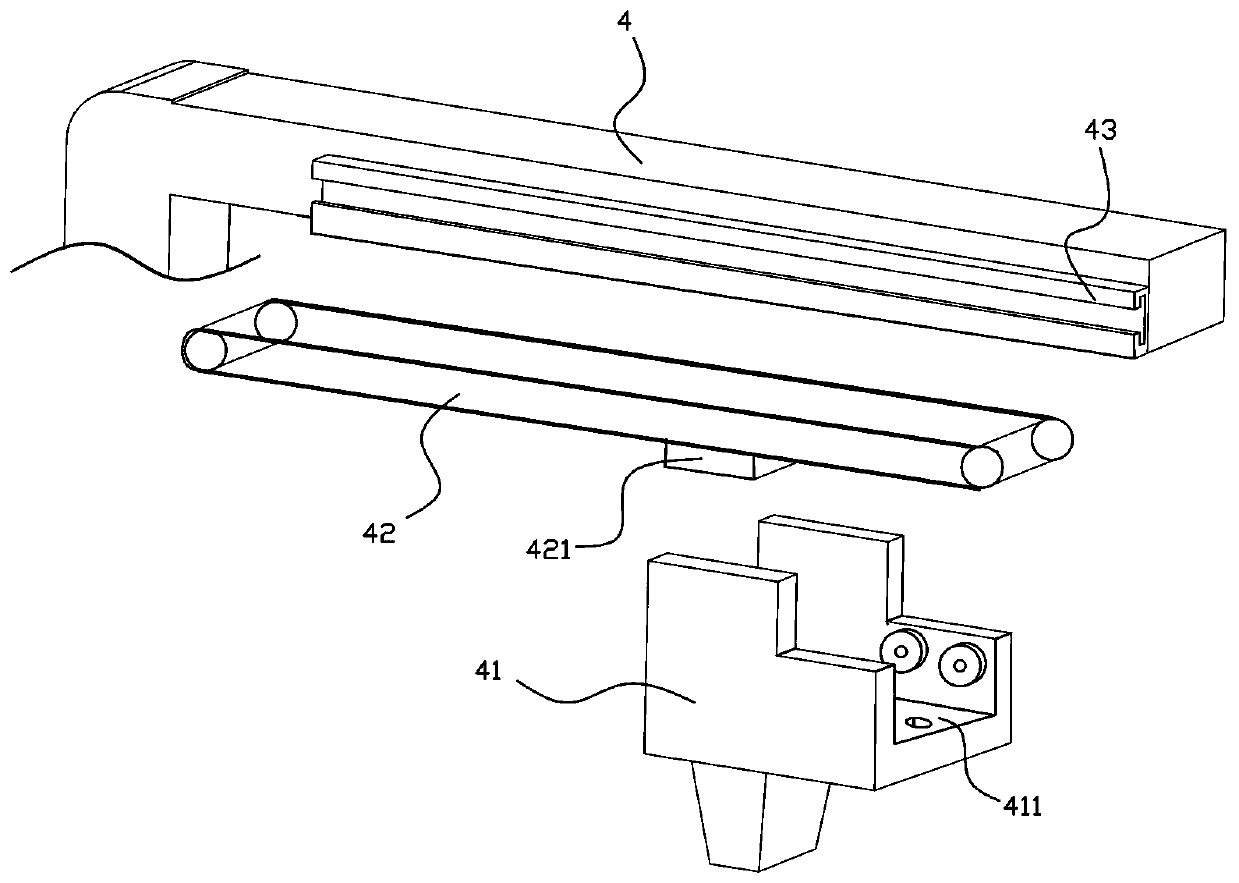

[0034] The difference between this embodiment and the previous embodiments is that a moving assembly is provided on the boom 4, and the nailing mechanism 41 is connected to the moving assembly, driven by the moving assembly, it can move along the boom 4. The length extension direction moves, and the moving assembly can be selected from an electric cylinder. Further, the moving assembly, the telescopic arm 61, the second clamping mechanism 62, the second clamping mechanism 62, and the nailing mechanism 41 are preferably driven by different drive motors, and These drive motors are all electrically connected with the electric control box. To sum up, it is beneficial to bind the cardboard by moving the nailing mechanism 41 along the length extension direction of the boom 4 when the cardboard is inconvenient to move (when the cardboard is large or easily damaged), which is beneficial to the combination of the nail box machine The other mechanisms on it adjust the binding mode reaso...

Embodiment 3

[0044] Such as Figure 5As shown, the present embodiment provides a semi-automatic nail box machine, including a chassis, a column 2, a beam 3, a boom 4 and a motor, the end of the boom 4 is provided with a nailing mechanism 41, and the column 2 is provided with a In the electric control box for controlling the motor, the electric control box is electrically connected with a foot switch, and the beam 3 is provided with a first clamping mechanism 5 that can reciprocate along the extending direction of the beam 3 length. Side arms 21 are respectively extended on both sides of the column 2, and each side arm 21 is provided with a support arm parallel to the crossbeam 3. One end of the support arm is connected to the side arm 21 and can be moved along the The side arm 21 reciprocates along the length extension direction, and the support arm 7 is provided with a second clamping mechanism 62 that can reciprocate along the length extension direction. The cooperation between the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com