System and method for large-scale preparation of ethylene glycol from synthesis gas

A technology for the synthesis of ethylene glycol, which is applied in the preparation of hydroxyl compounds, organic compounds, carbon monoxide or formate reaction preparation, etc., which can solve the problems of low qualification rate of ethylene glycol products, large number of device series, and large project investment and other problems, to achieve the effect of reducing the steam consumption of ethylene glycol rectification and separation, reducing the project investment, and reducing the project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

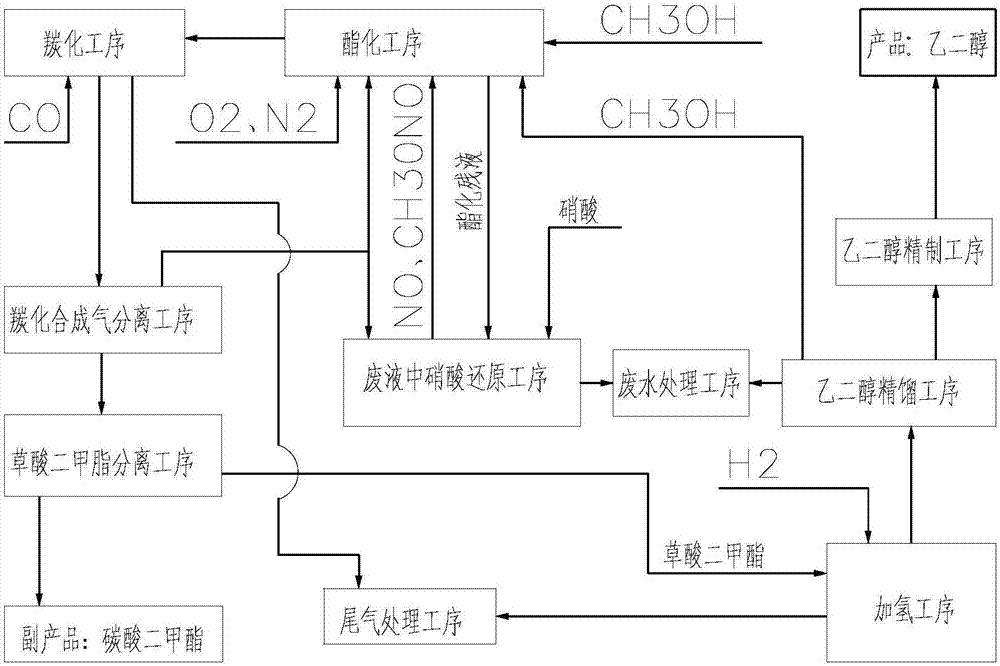

[0067] Such as figure 1 As shown, this embodiment includes esterification process, carbonylation process, carbonylation synthesis gas separation process, dimethyl oxalate separation process, hydrogenation process, ethylene glycol rectification process, ethylene glycol refining process, waste liquid treatment process , Tail gas treatment process, the above processes and main equipment are single-series single-unit, truly realizing the large-scale production of ethylene glycol from syngas.

[0068] Concretely prepare the steps of ethylene glycol as follows:

[0069] (1) Esterification process: complete the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com