High-sulfur power raw coal sorting process

A power and sorting technology, applied in the direction of solid separation, etc., can solve the problems of high operating cost, low separation accuracy of gravity coal separation, and many system links, and achieve the effect of reduced operating cost, low production cost and simplified system links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

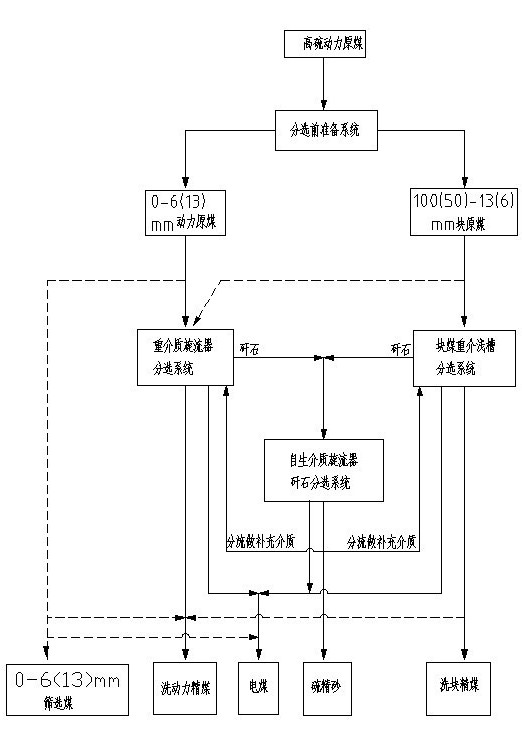

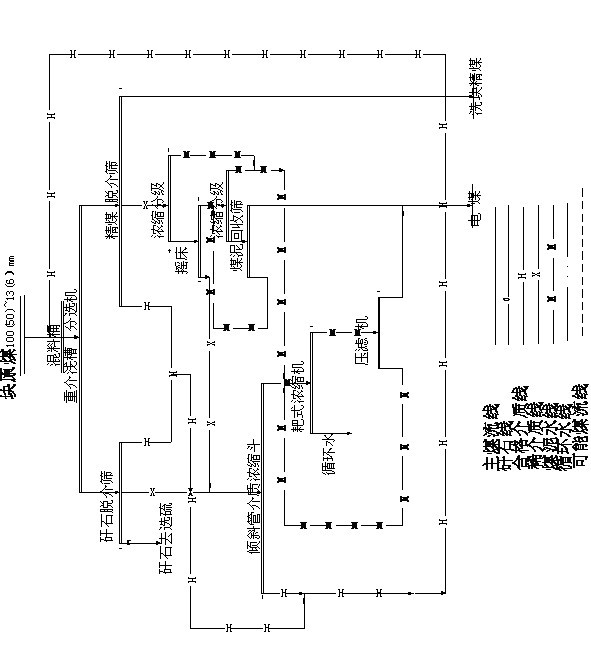

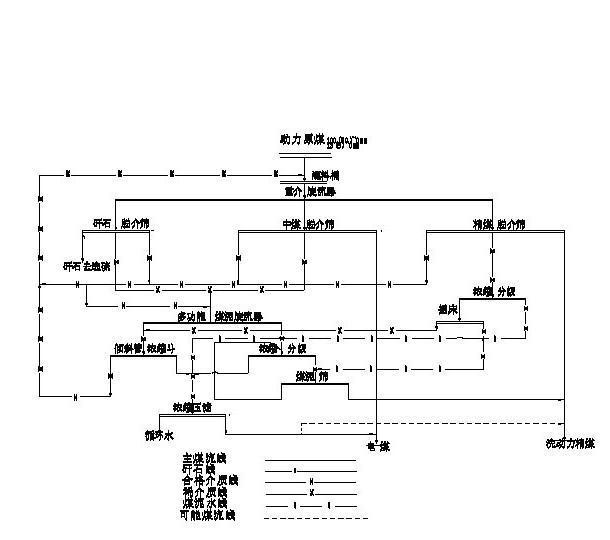

Embodiment 1

[0030] A sorting process for high-sulfur power raw coal, which is characterized in that: firstly, the high-sulfur power raw coal is prepared to produce 100(50)-13(6)mm block raw coal and 13(6)-0mm power raw coal through the pre-sorting preparation system, The 100(50)-13(6)mm block raw coal enters the lump coal dense medium shallow tank separation system, and the washed clean coal (washed clean coal can be used as the coal blending base material for washing power clean coal), electric coal and gangue , or enter the dense medium cyclone sorting system together with 13(6)-0mm power raw coal for separation, and wash power clean coal, electric coal and gangue; 13(6)-0mm power raw coal alone as 13(6) -0mm screened coal or used as coal blending base material for washing power clean coal or as coal blending base material for electric coal or entering dense medium cyclone sorting system for sorting, washing power clean coal and gangue; among them, lump coal heavy medium The gangue prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com