Patents

Literature

211results about How to "Simple demodulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

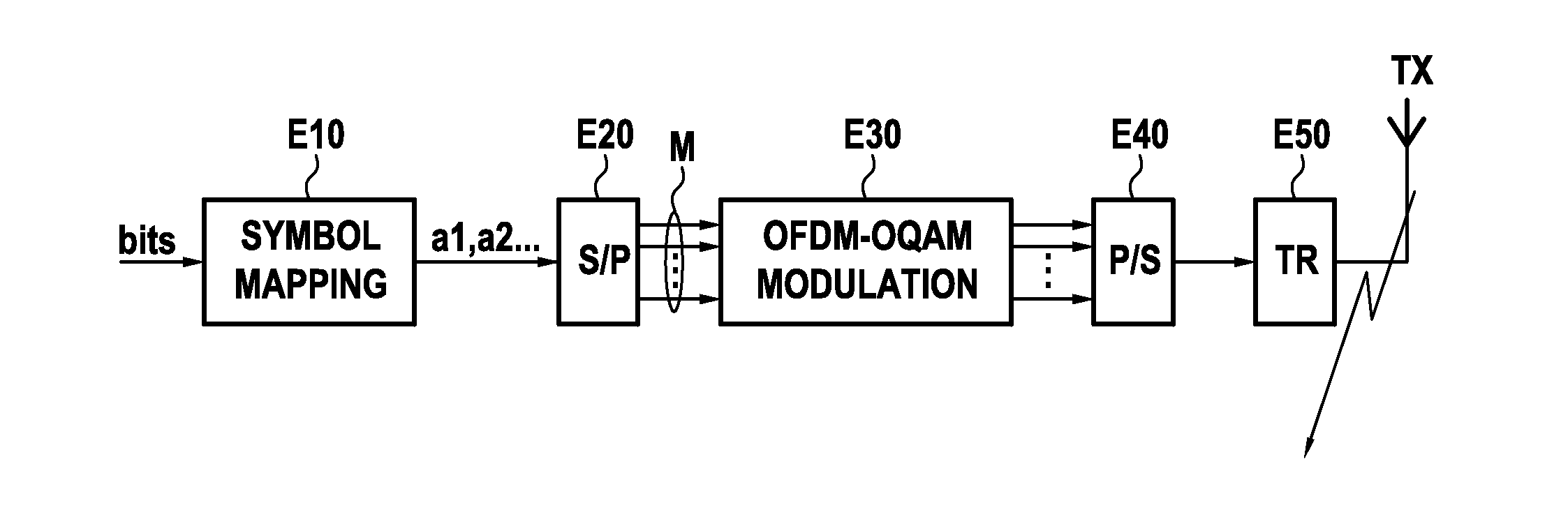

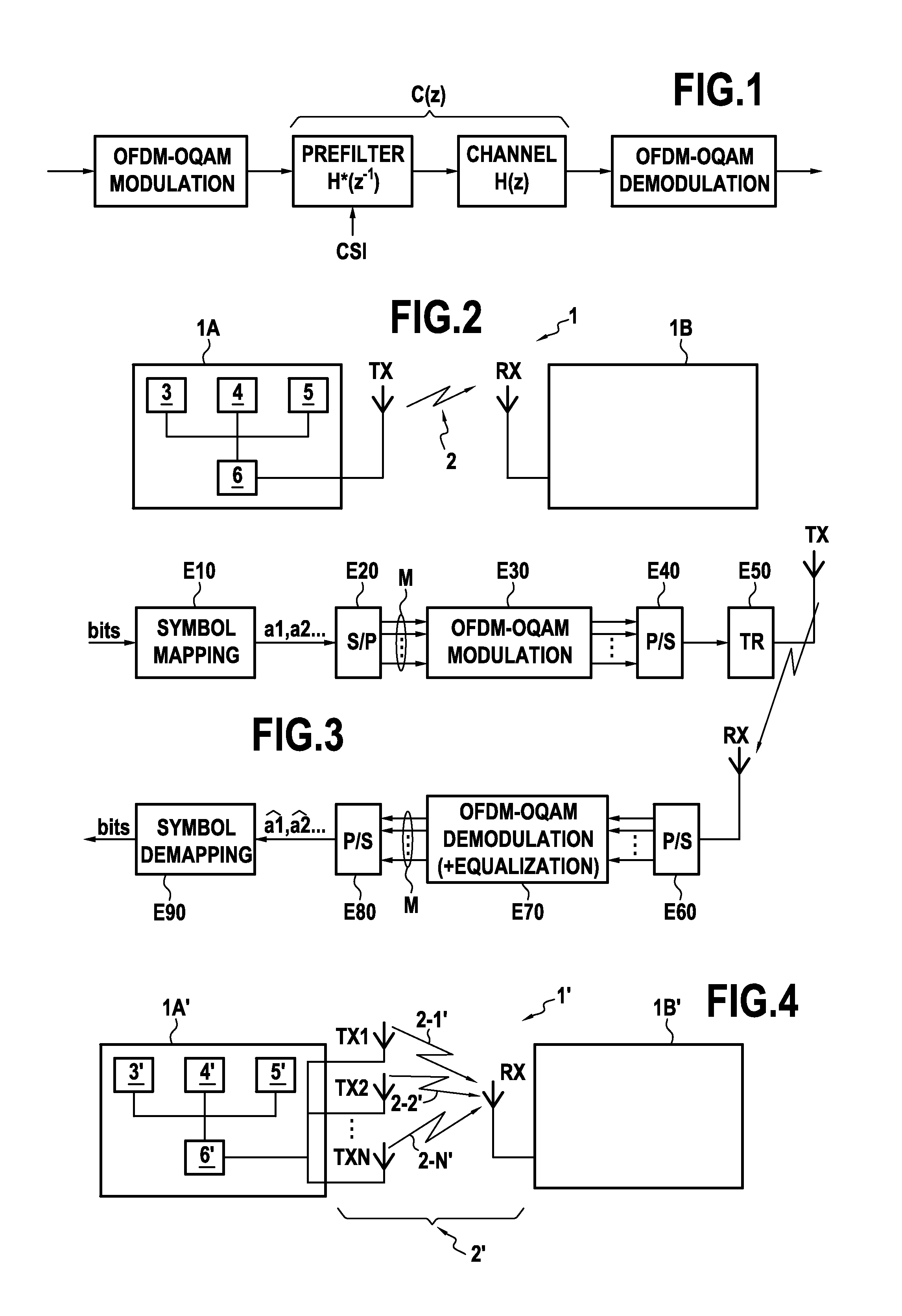

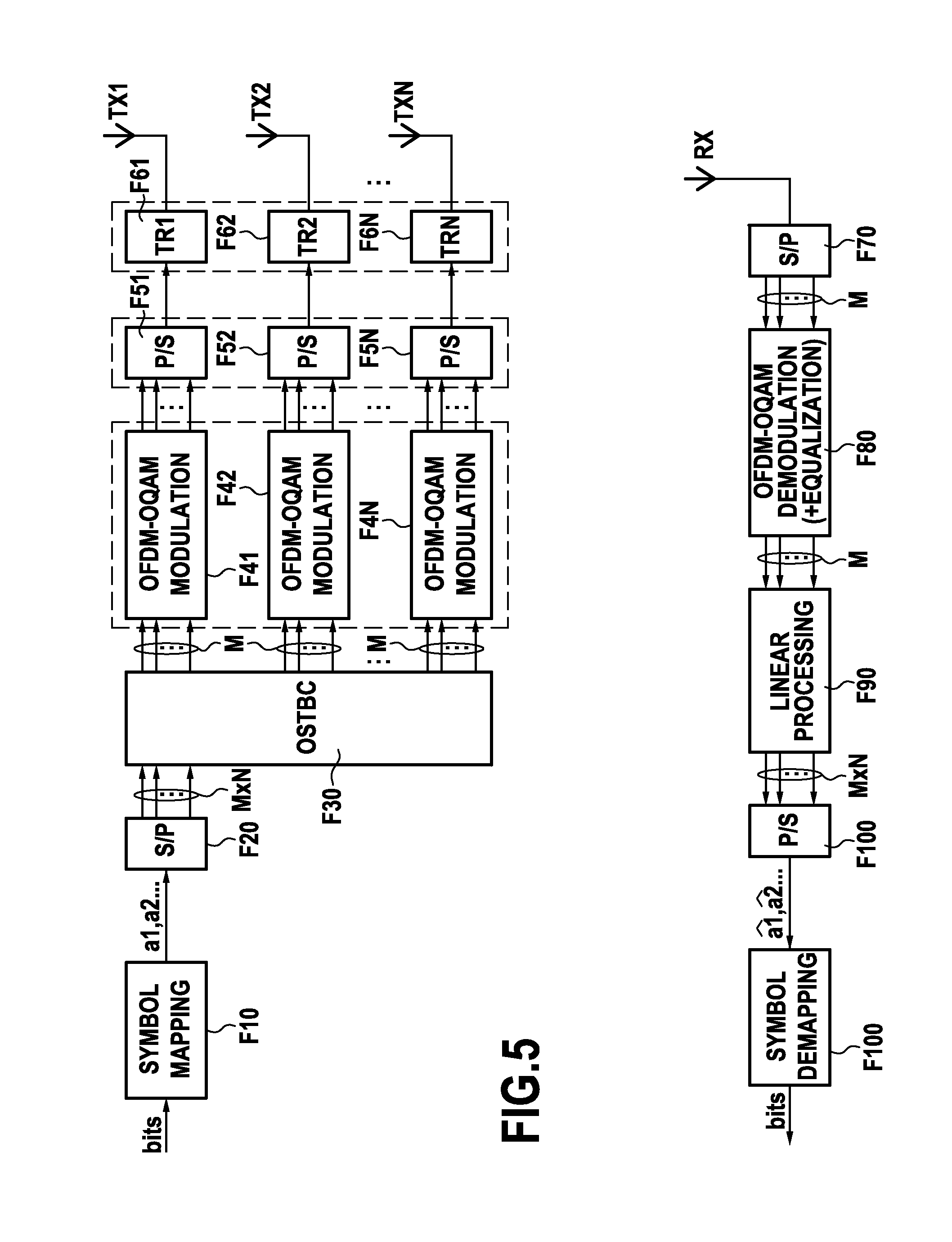

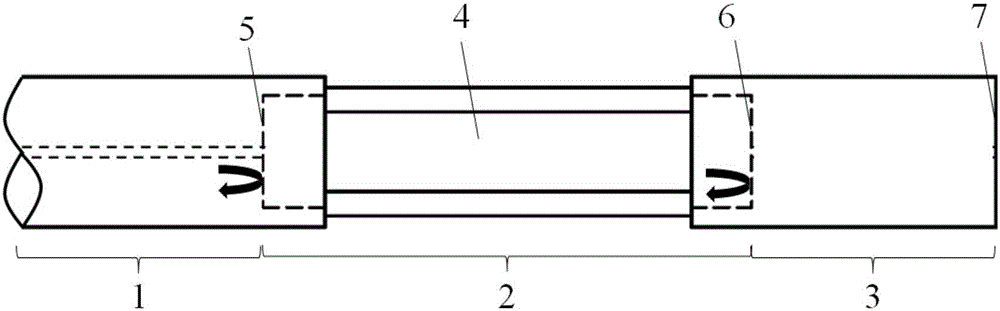

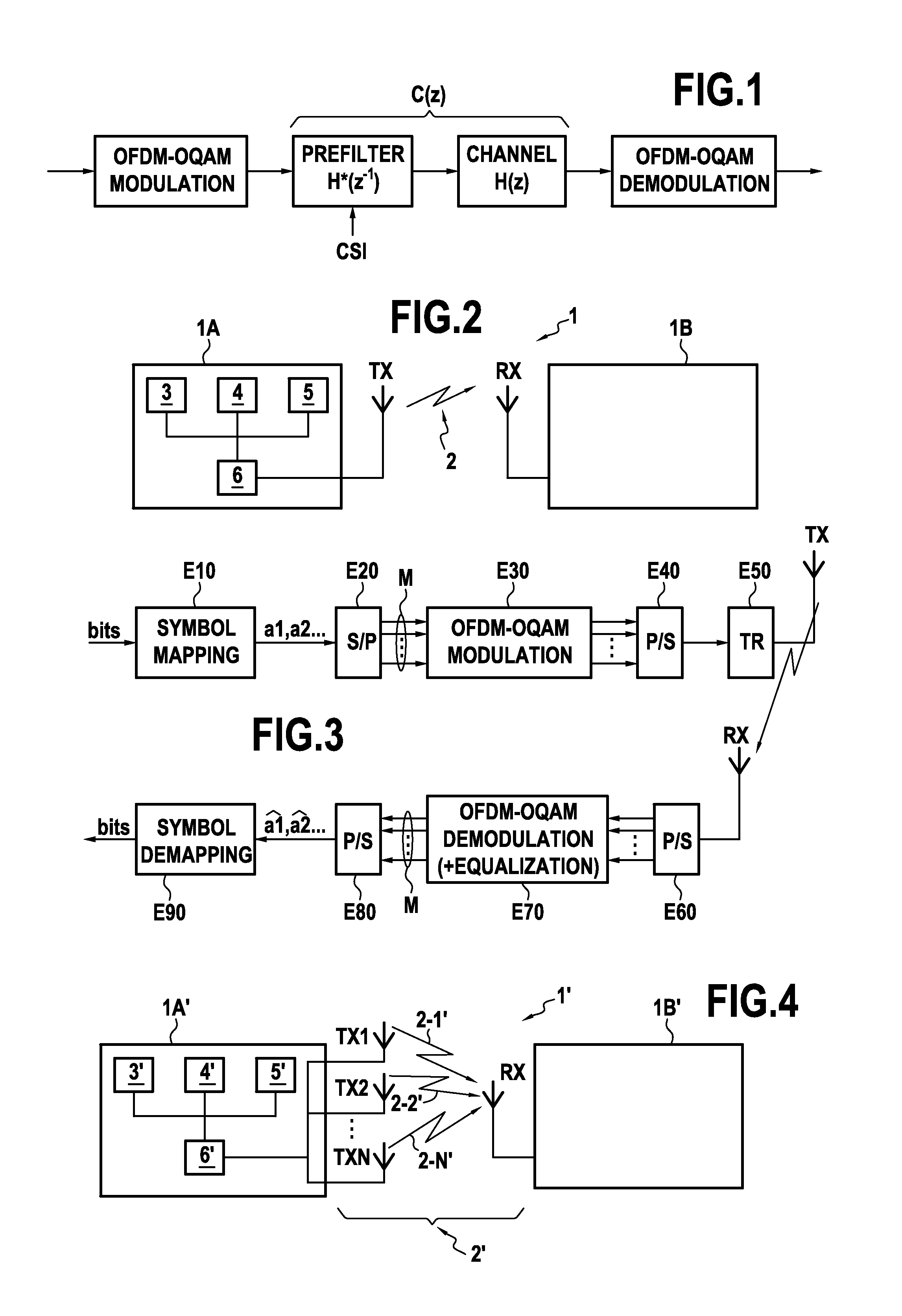

Method for transmitting at least one multi-carrier signal consisting of ofdm-oqam symbols

ActiveUS20140348252A1Avoid it happening againMaximize Spectral EfficiencyError preventionRadio transmissionTransmission channelEngineering

Disclosed is a transmission method of transmitting at least one multicarrier signal made up of OFDM-OQAM symbols to a receive antenna of a receiver device, the transmission method being for use by a transmitter device having at least one transmit antenna. In one embodiment, the method comprises, for each transmit antenna of the transmitter device, filtering OFDM-OQAM symbols associated with the transmit antenna using a time-reversal prefilter defined from an estimate of the transmission channel between the transmit antenna and the receive antenna and transmitting the filtered OFDM-OQAM symbols via the transmit antenna over the transmission channel.

Owner:ORANGE SA (FR)

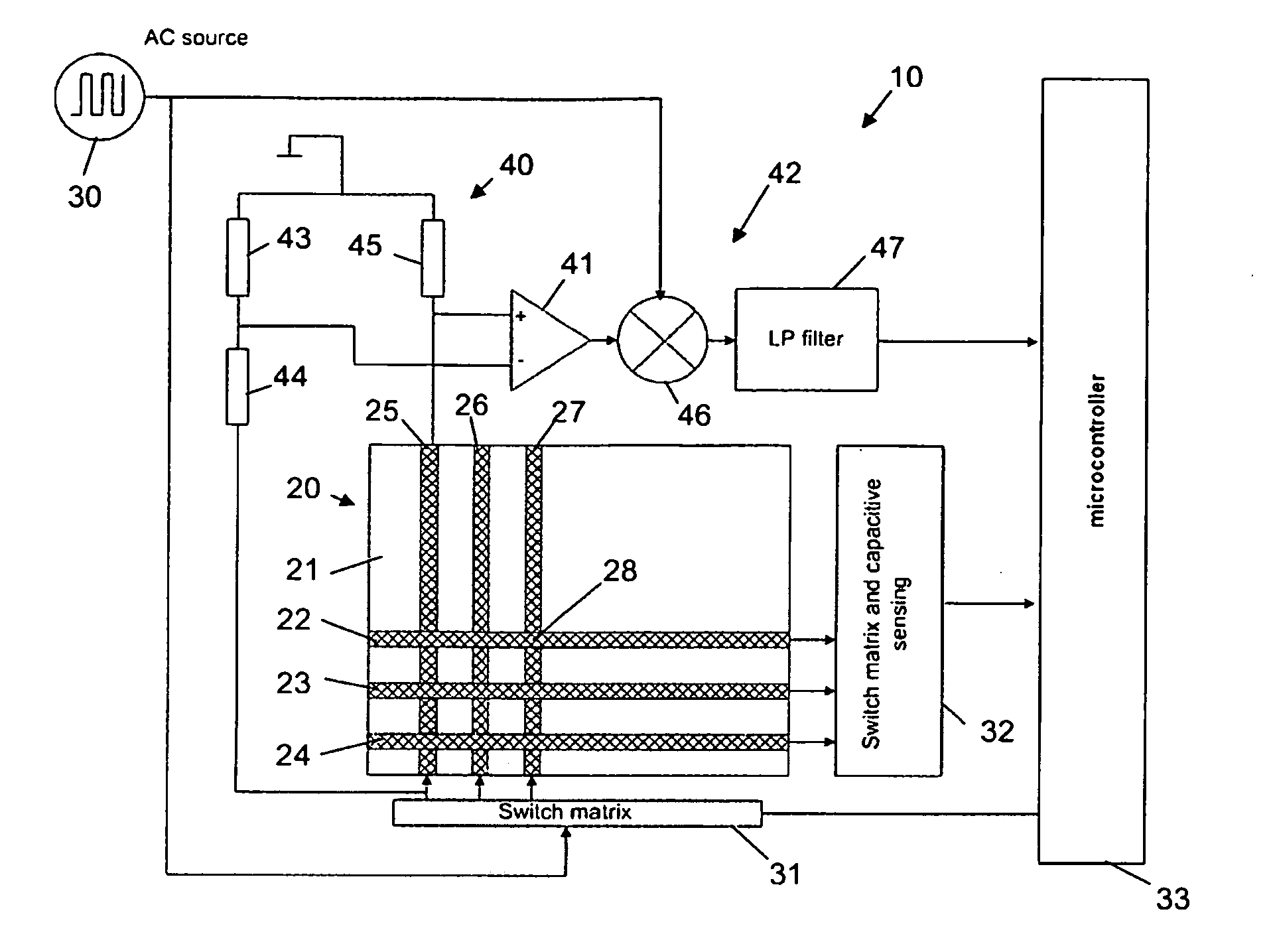

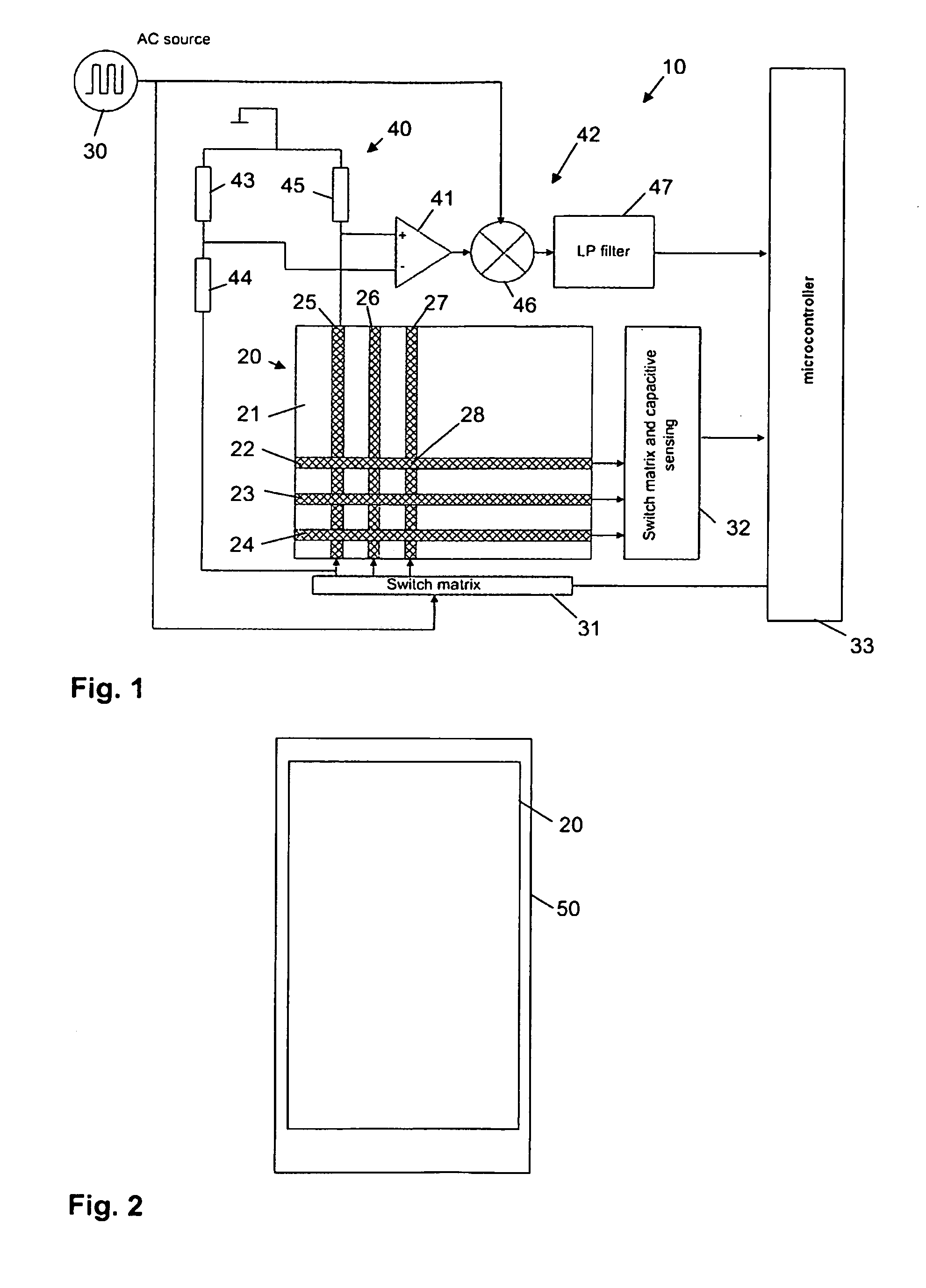

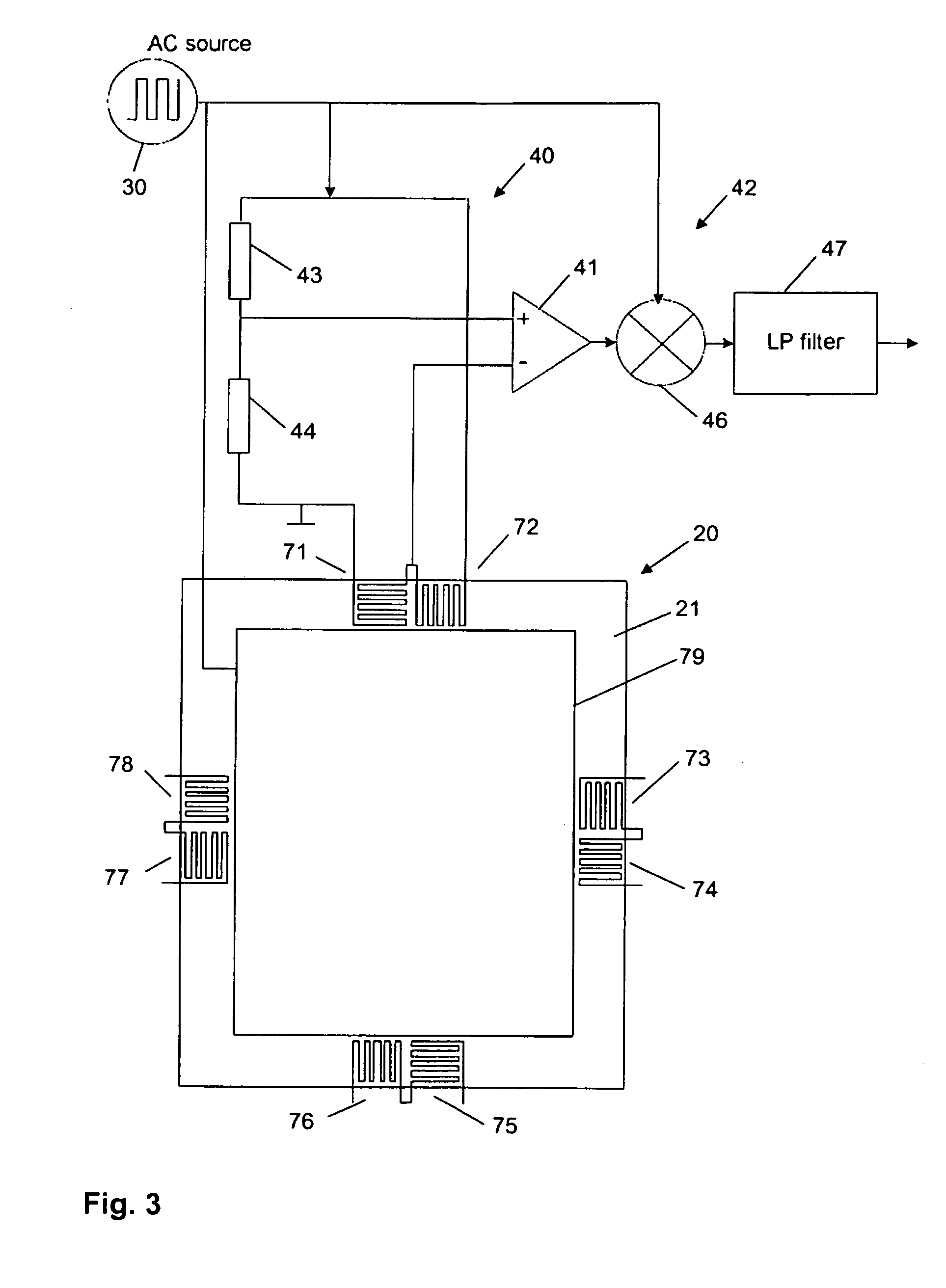

Method for controlling a touch sensor

InactiveUS20150002452A1Easy to detectReduce noise levelDigital data processing detailsInput/output processes for data processingCapacitanceElectrical resistance and conductance

The present invention relates to a method for controlling a touch sensor. The touch sensor comprises a support layer and an electrically conductive sensor structure thereon. The electrically conductive sensor structure forms a plurality of capacitors having a capacitance varying in response to a user touching or approaching the capacitor. The electrically conductive sensor structure comprises a piezoresistive material providing a resistance varying in response to a force being applied to the support layer. According to the method, an alternating electrical signal is supplied to the electrically conductive sensor structure for scanning the capacitors. An actuation position where the user touches the touch sensor is determined based on the alternating electrical signal and the capacitances of the capacitors. An electrical signal which is a function of the resistance of the electrically conductive sensor structure is detected and synchronously demodulated based on the alternating electrical signal.

Owner:SONY MOBILE COMM AB

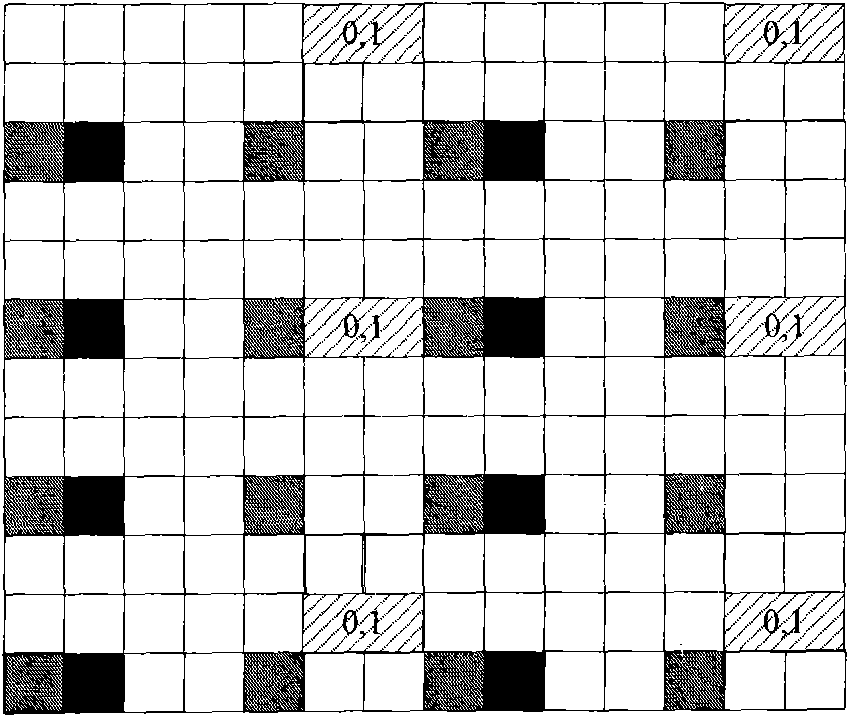

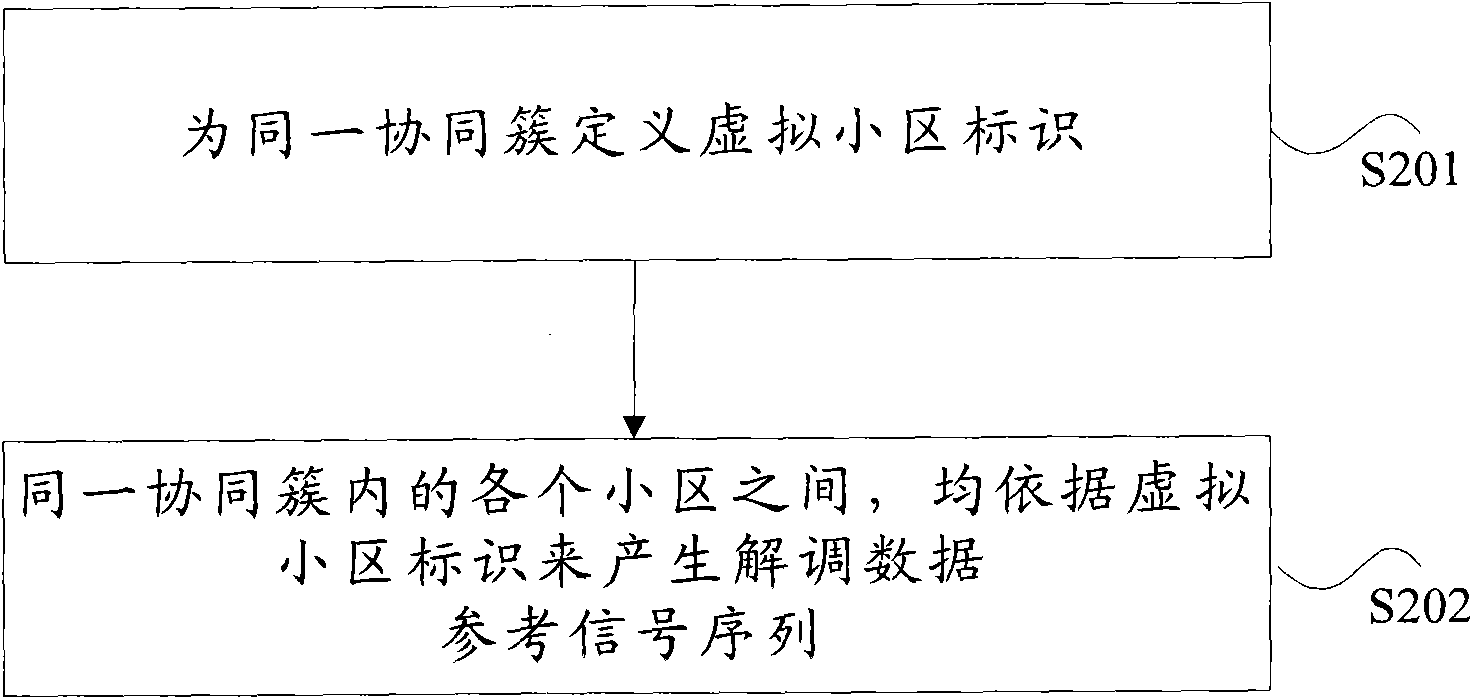

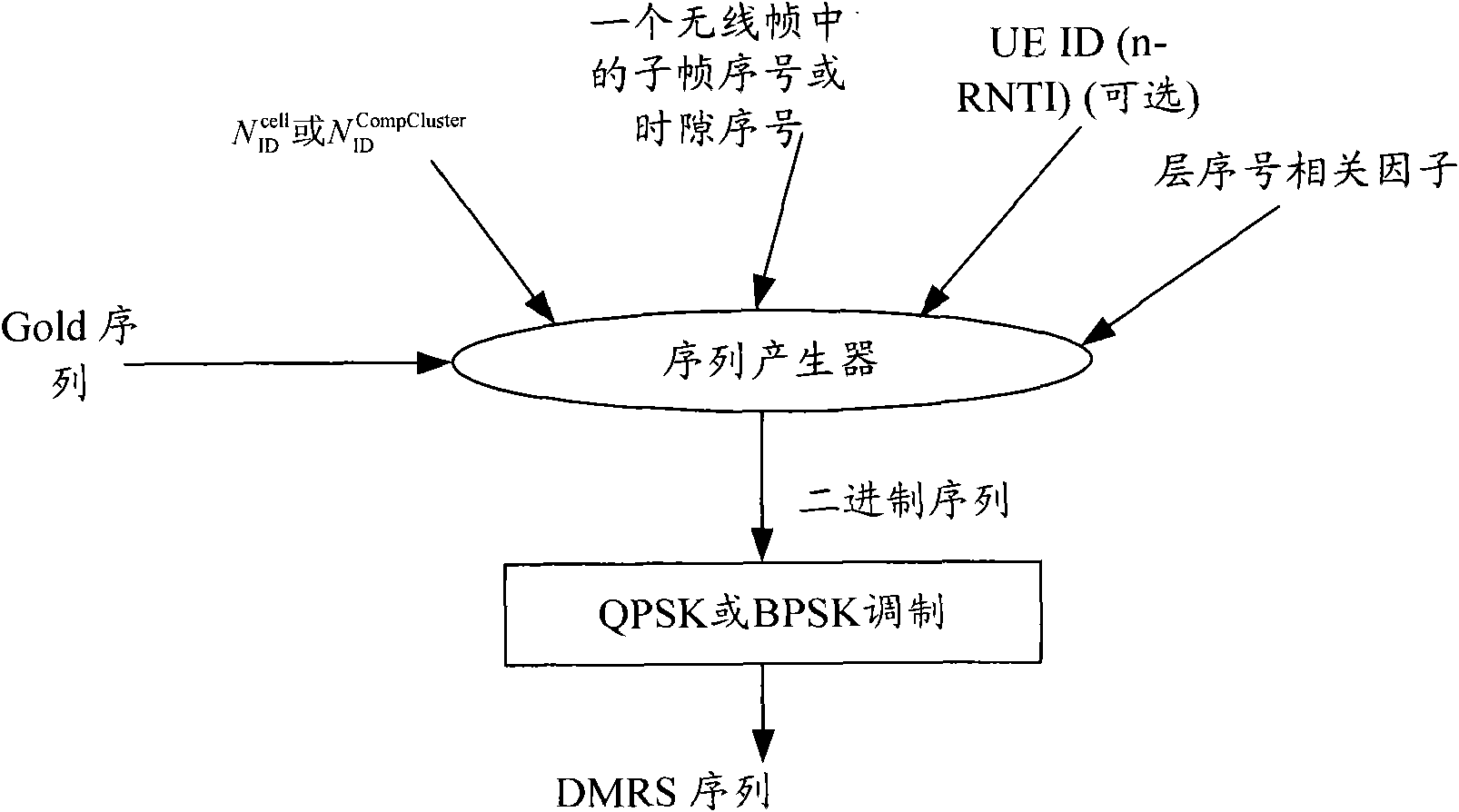

Method and device for demodulating data reference mark sequence

InactiveCN102055519ASolve complex problems of demodulationSimple demodulationModulated-carrier systemsRadio transmission for post communicationVirtual cellAlgorithm

The invention discloses a method and device for demodulating a data reference mark sequence. In the method, when a pilot frequency sequence of a data demodulation pilot frequency DMRS (Demodulation Reference Signal) is generated, the same DMRS sequence generation method is adopted for all cells corresponding to the same cooperative cluster. The method can comprise the steps of: defining virtual cell identification for the same cooperative cluster; and generating the DMRS sequence according to the virtual cell identification among all the cells inside the same cooperative cluster. By means of the invention, the problem that the demodulation of the data reference mark sequence is relatively complicated is solved, and the effect of demodulating the data reference mark sequence simply and conveniently is further achieved.

Owner:ZTE CORP

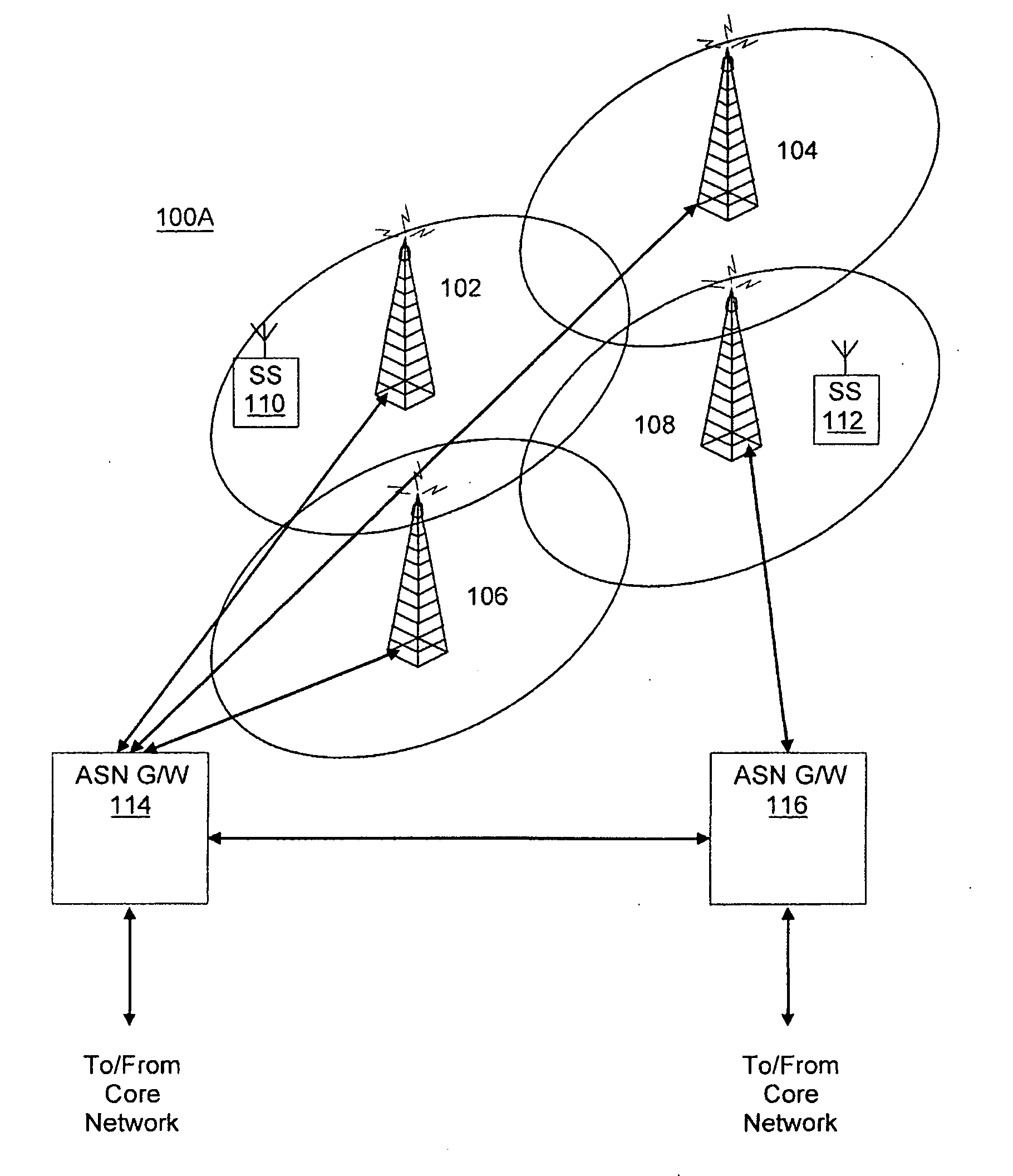

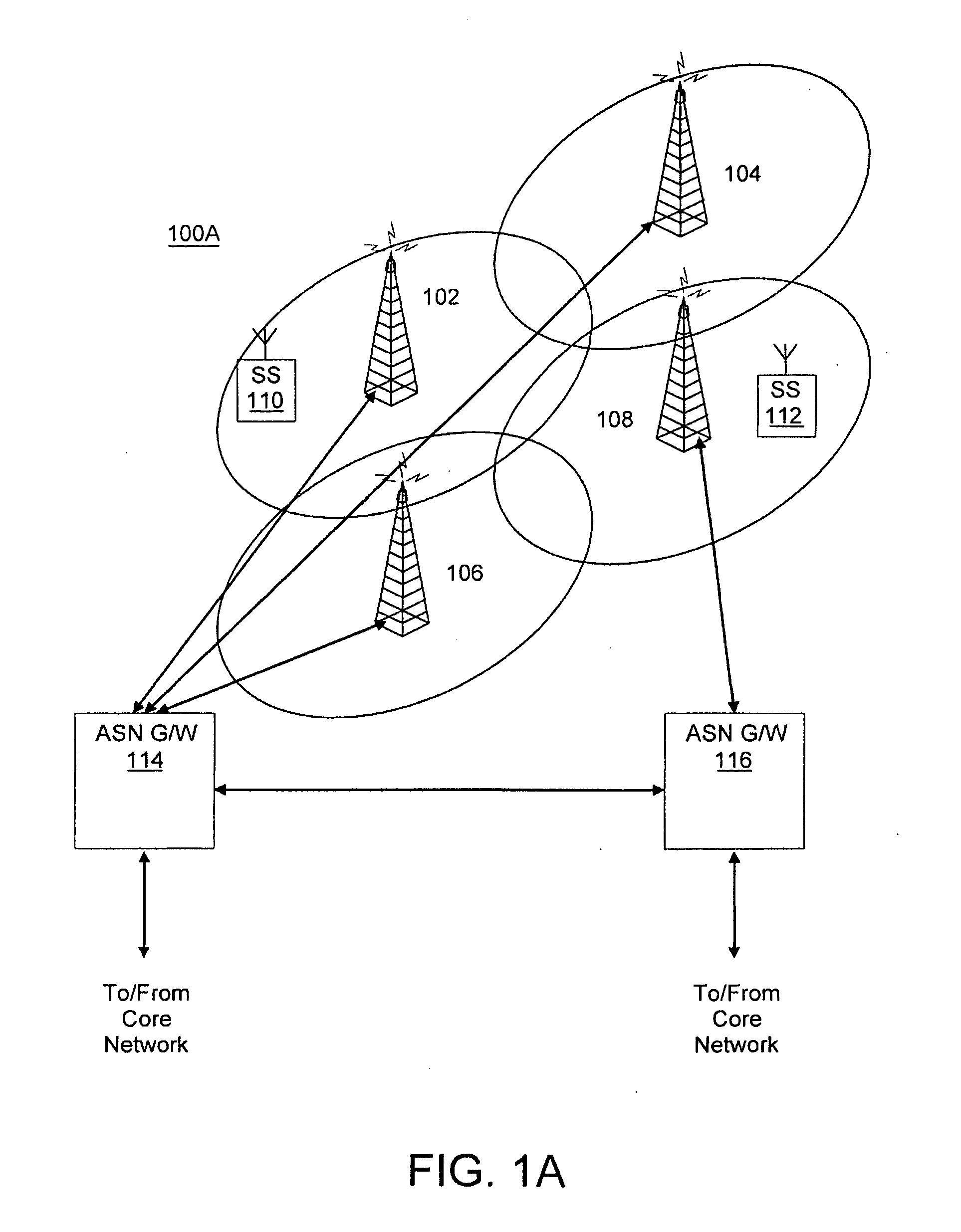

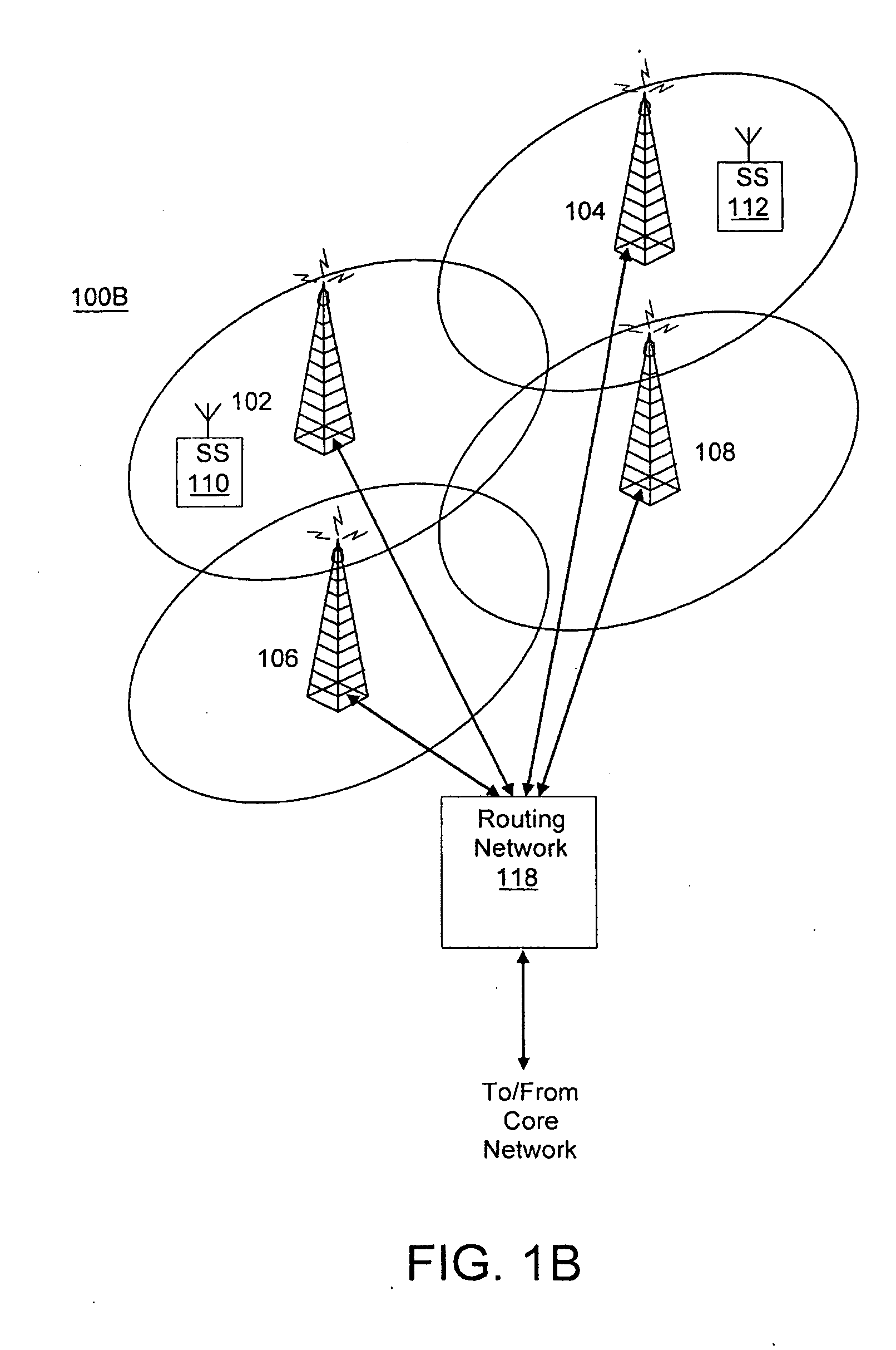

Using a synchronization channel to send quick paging signals

InactiveUS20100040015A1Simple demodulationIncrease powerEnergy efficient ICTSynchronisation arrangementCommunications systemPaging

In an orthogonal frequency division multiple access communication system, a base station transmits a quick paging signal simultaneously with a synchronization signal during the same transmission symbol time period. Even though these different signals are transmitted during the same transmission symbol time period, a periodicity of the synchronization signal is maintained to facilitate rapid and cost-effective synchronization by subscriber stations with the base station. The quick paging signal alerts subscriber stations about whether to stay awake for a subsequent page or to go into a power saving sleep mode.

Owner:TELEFON AB LM ERICSSON (PUBL)

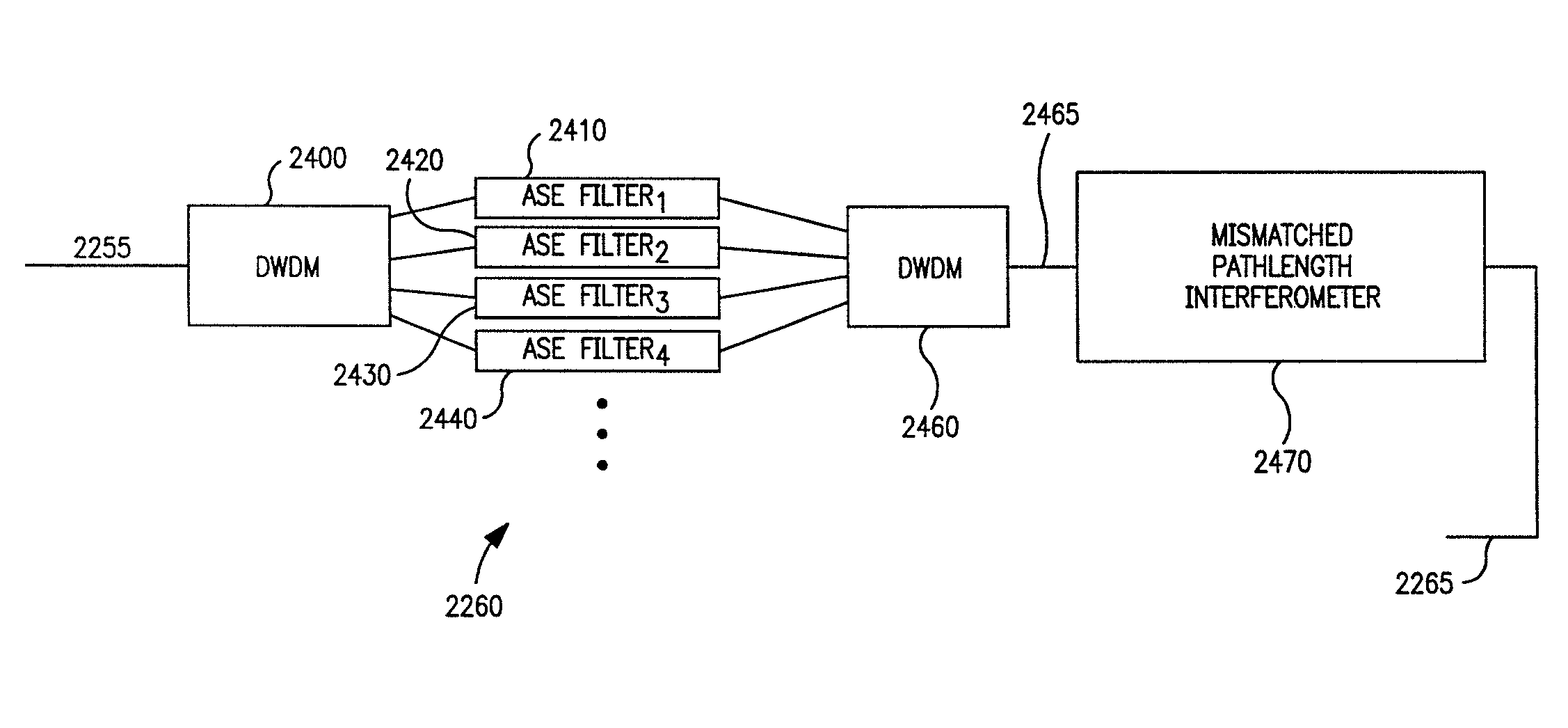

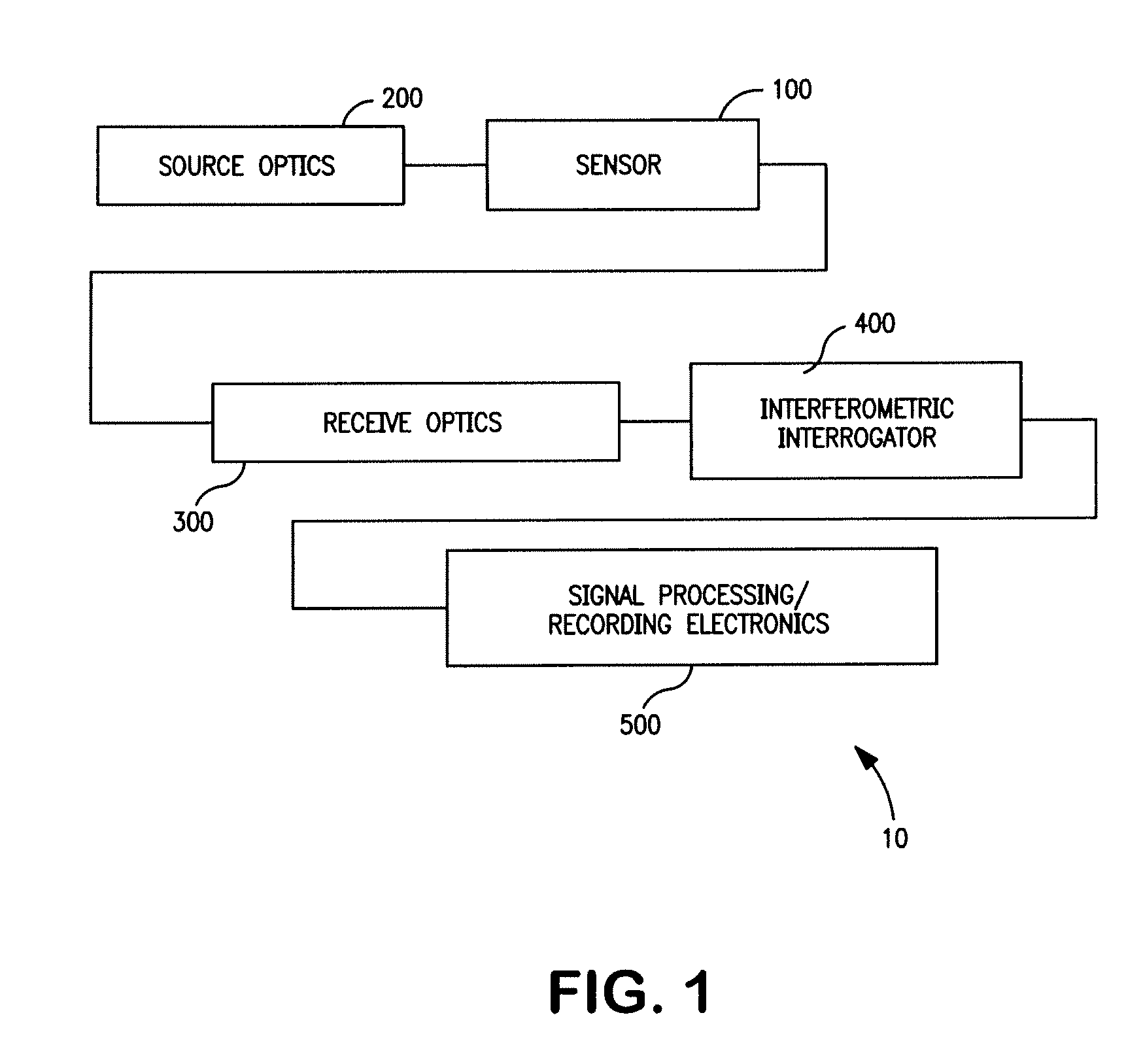

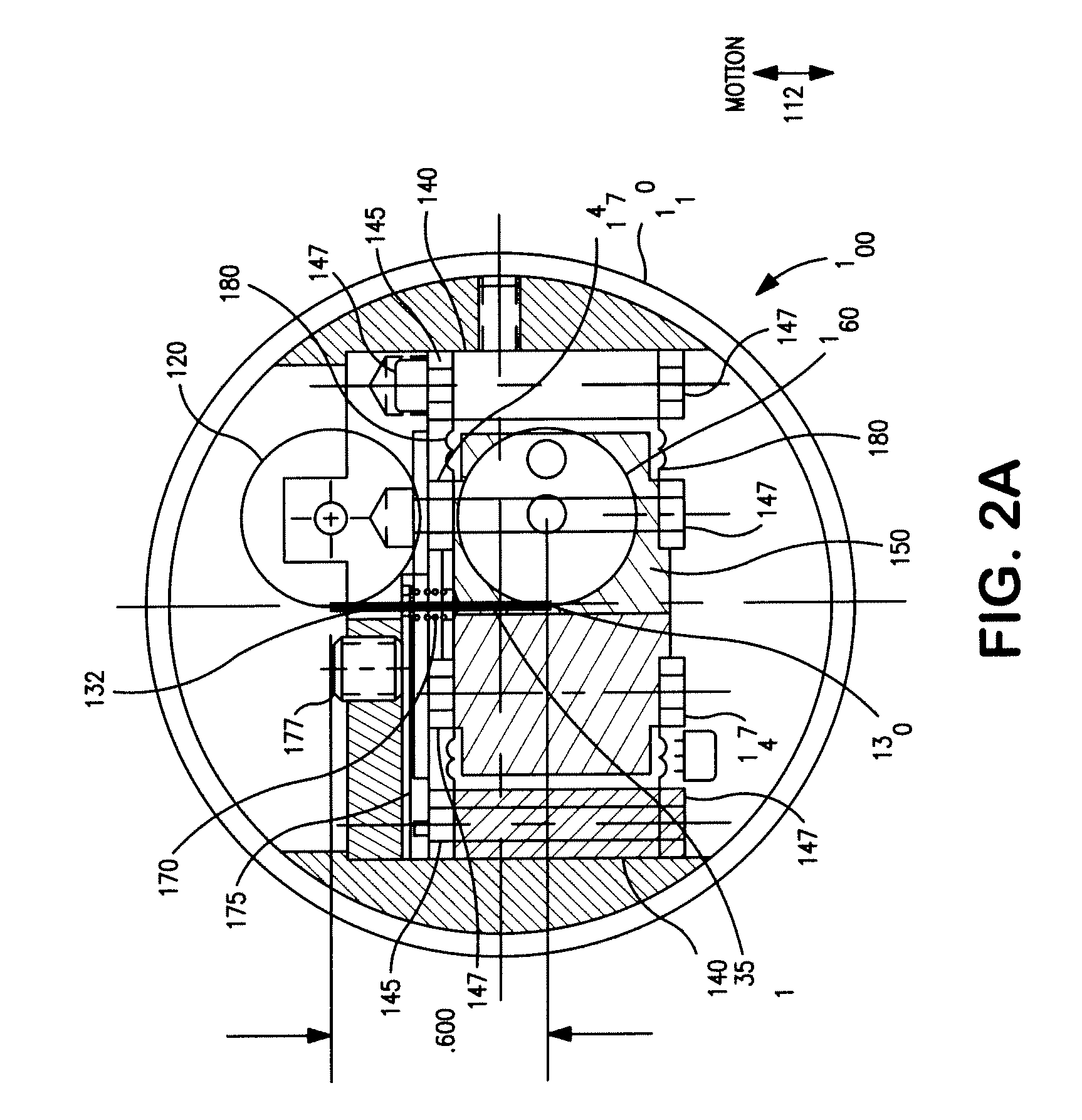

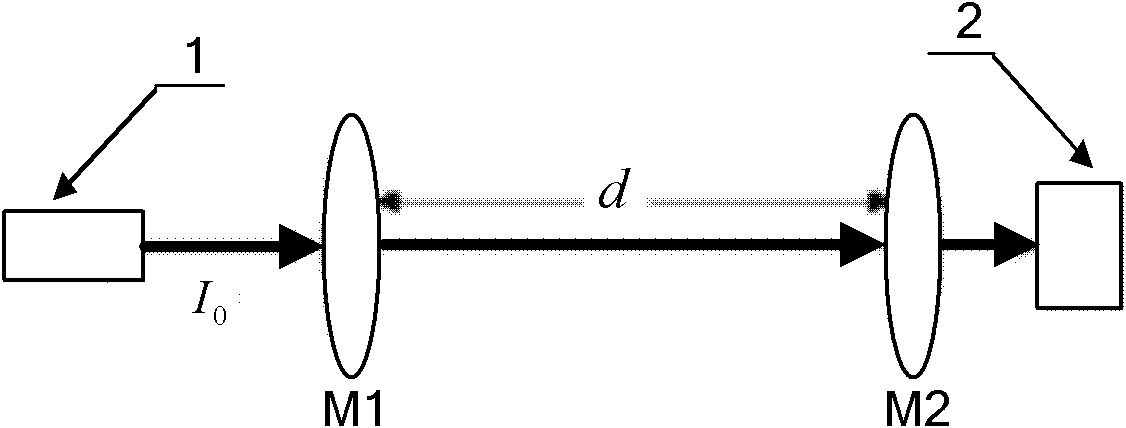

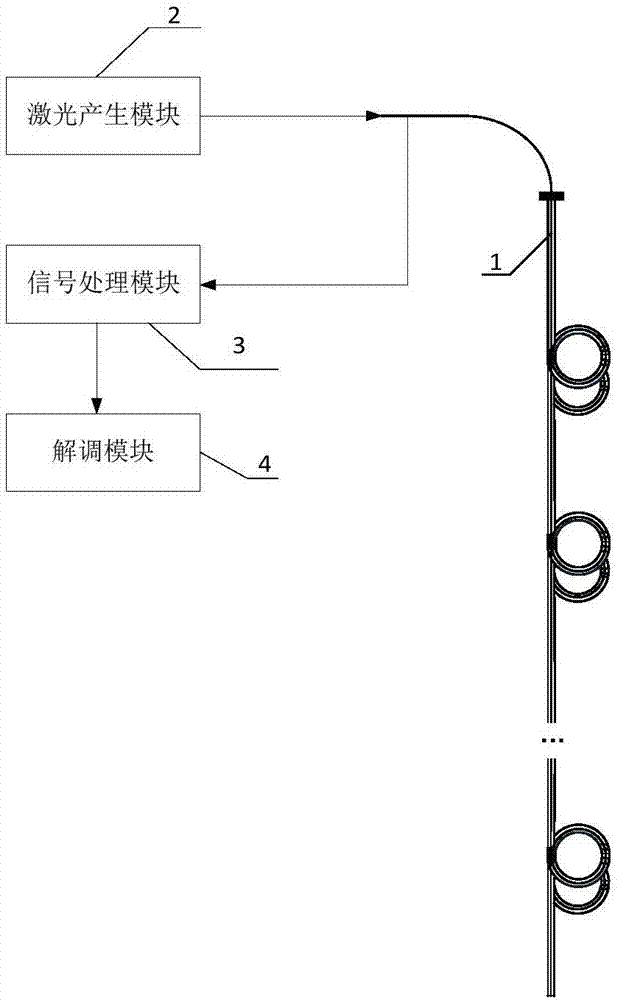

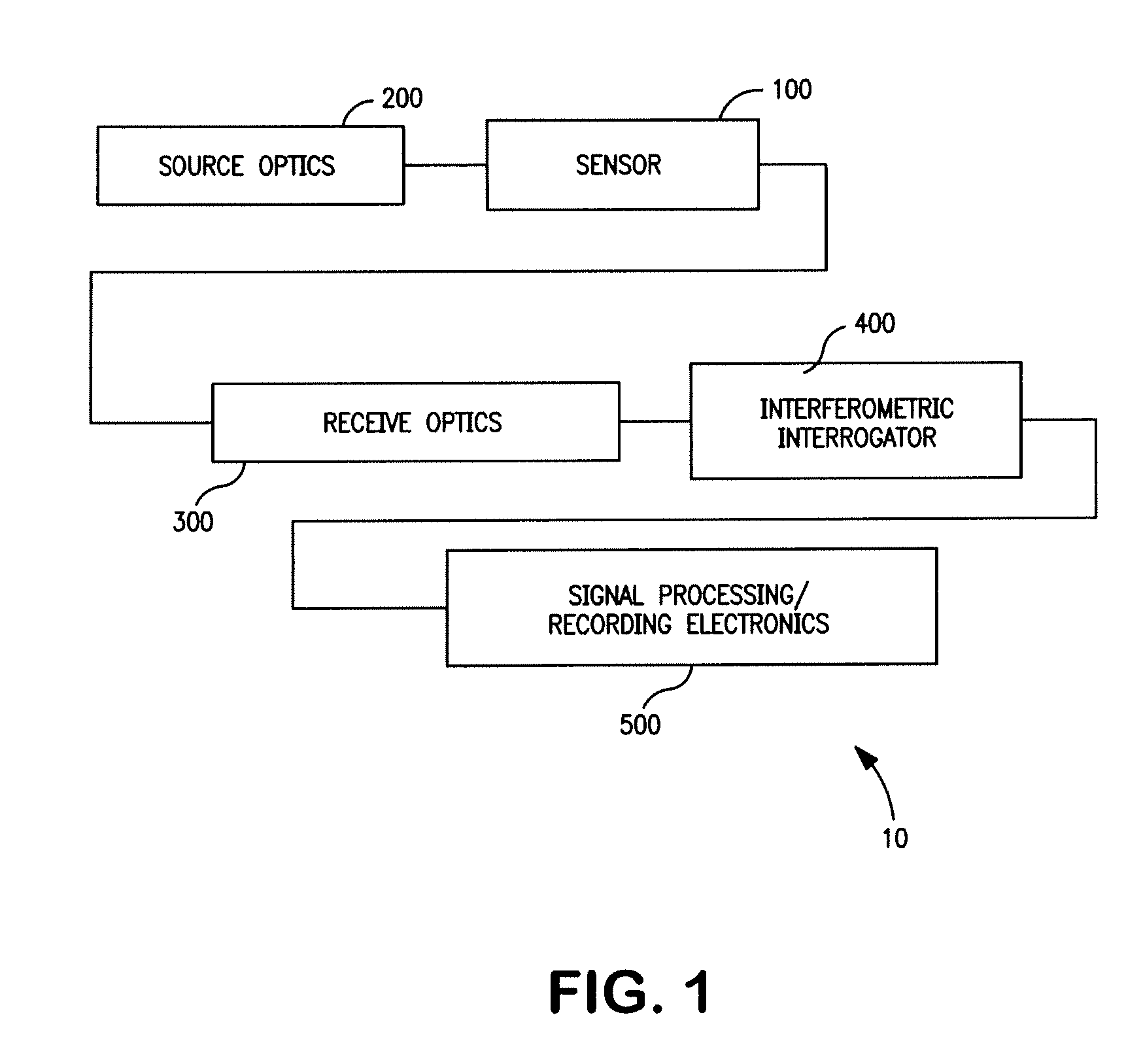

Fiber optic particle motion sensor system

ActiveUS7999946B2Simple demodulationLevel of performanceAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementPhase shiftedFiber interferometer

A sensor apparatus combines an optical sensor in which acceleration, acoustic velocity, or displacement (vibration) causes a corresponding shift in the center wavelength of the sensor output, coupled to a high speed interferometric interrogator, through an unbalanced fiber interferometer. The unbalanced interferometer functions to translate optical wavelength shift into phase shift, which is easily demodulated by the interrogator.

Owner:AVALON SCI

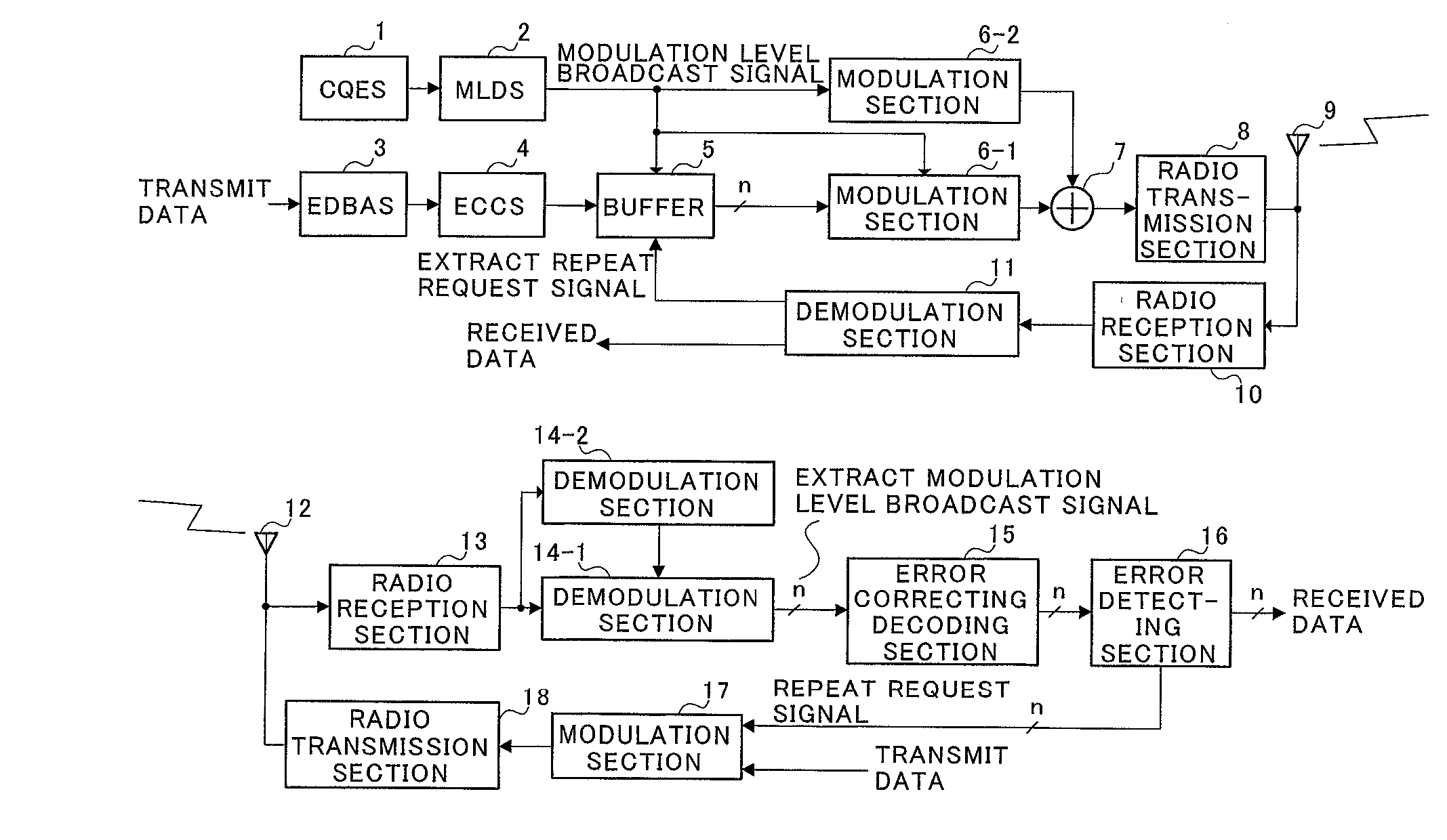

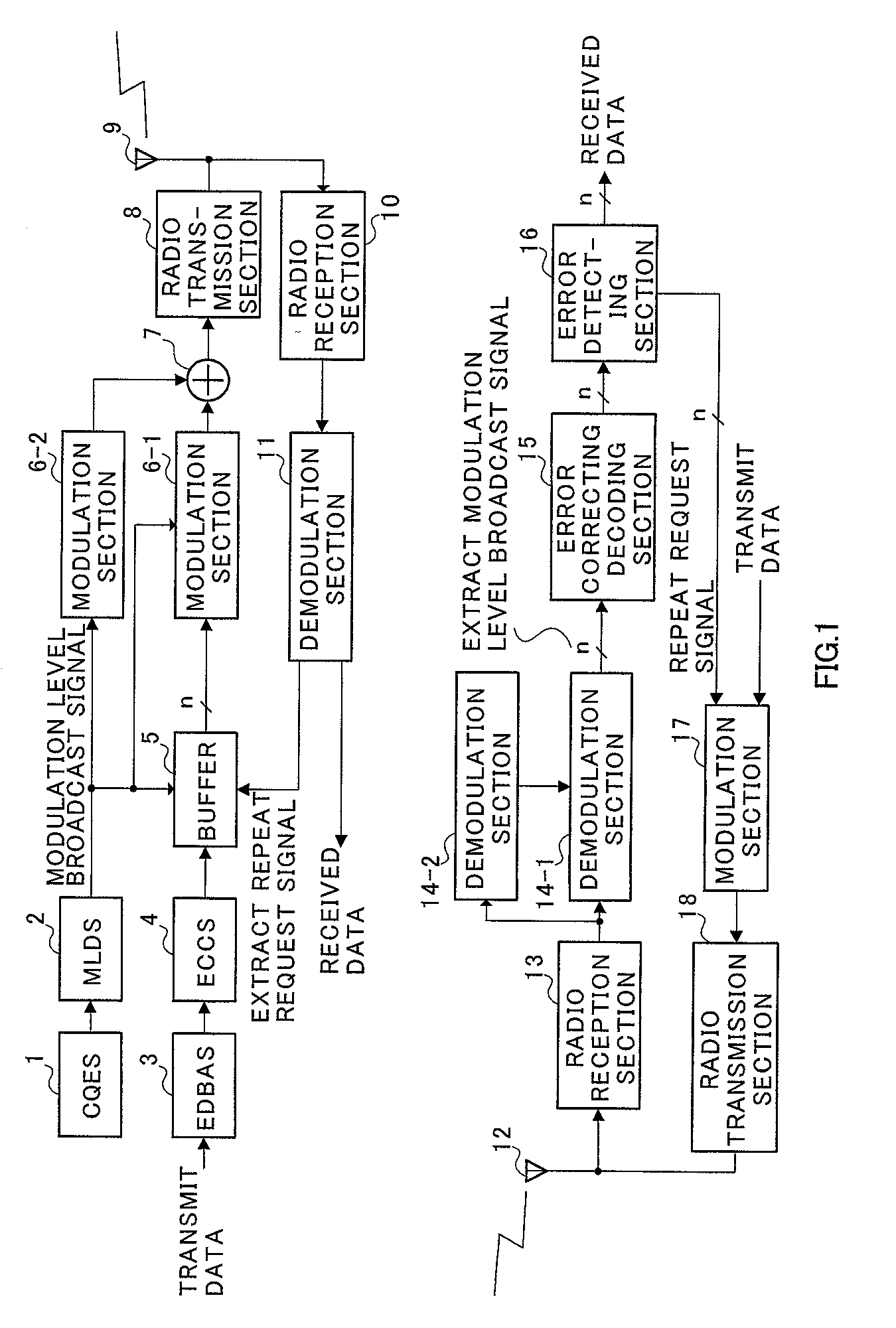

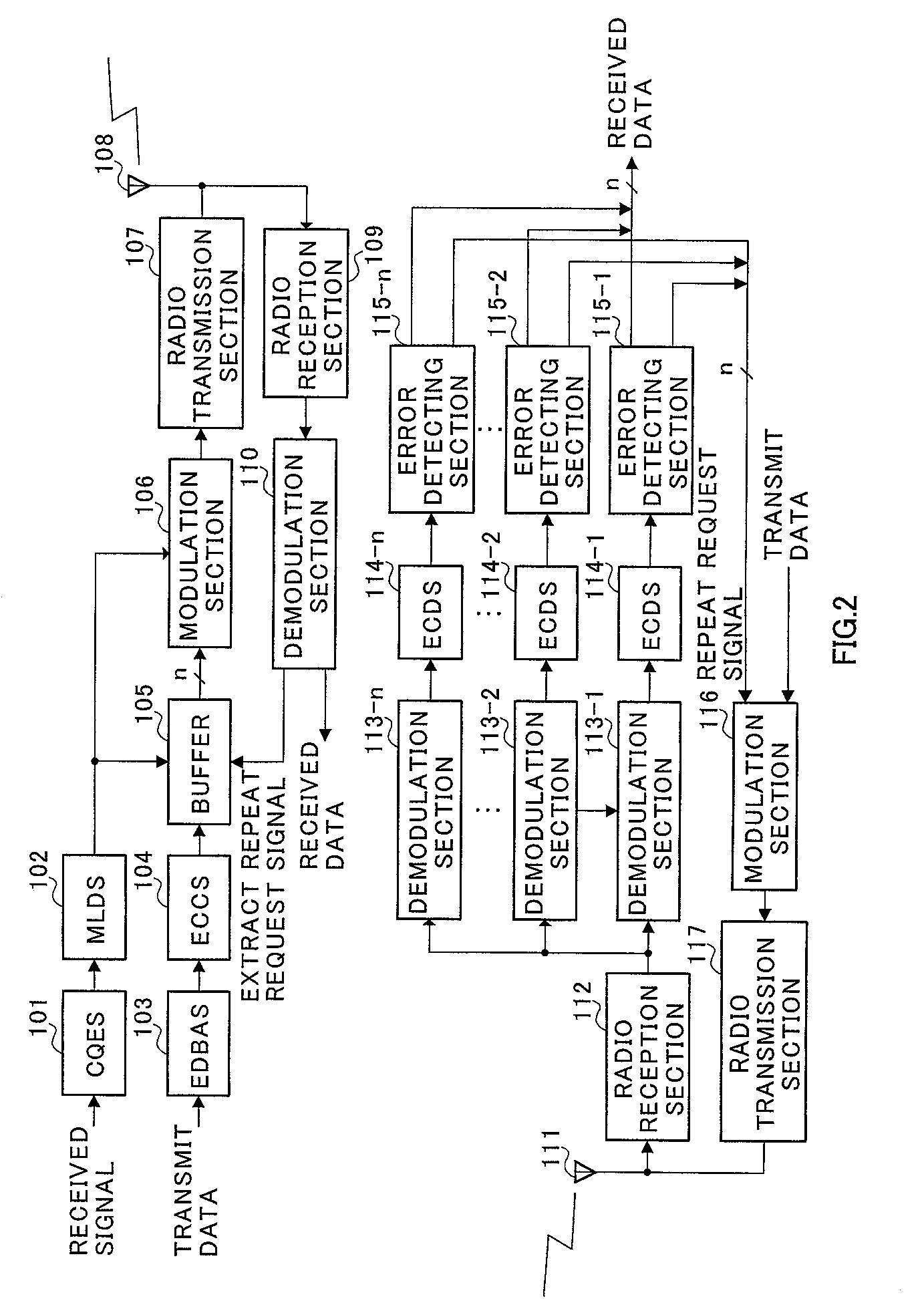

Adaptive modulation communication system

InactiveUS20020114379A1Simple demodulationError prevention/detection by using return channelMultiple modulation transmitter/receiver arrangementsData subjectSelf adaptive

In an adaptive modulation communication system that adaptively varies a modulation scheme for each transmit unit, a transmitting-side apparatus sets different error detecting units corresponding to bit position, and transmits data subjected to error detecting processing on a different error detecting unit basis corresponding to bit position, and a receiving-side apparatus performs demodulation independently for each of the error correcting units using different demodulation patterns to obtain received data.

Owner:PANASONIC CORP

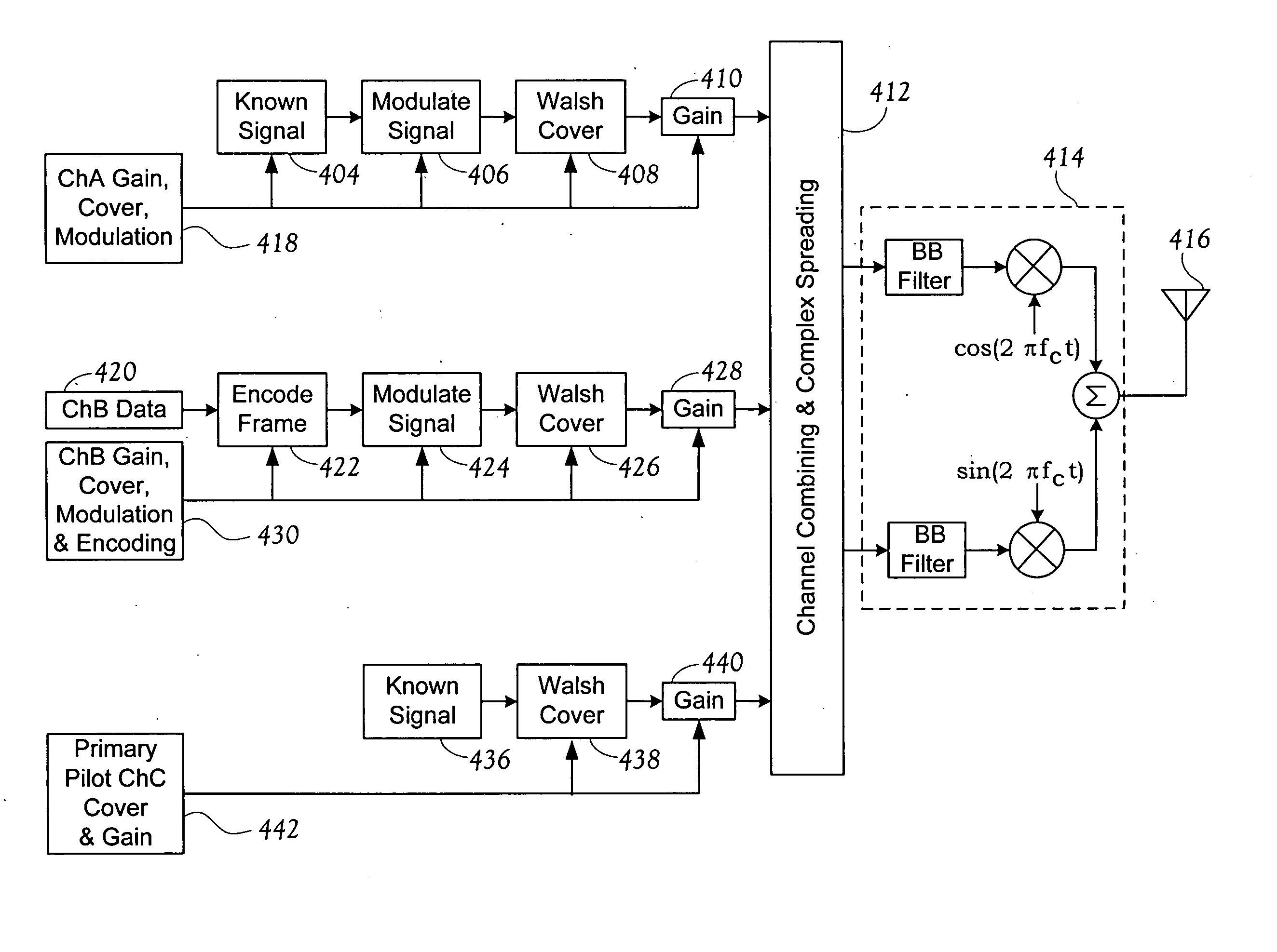

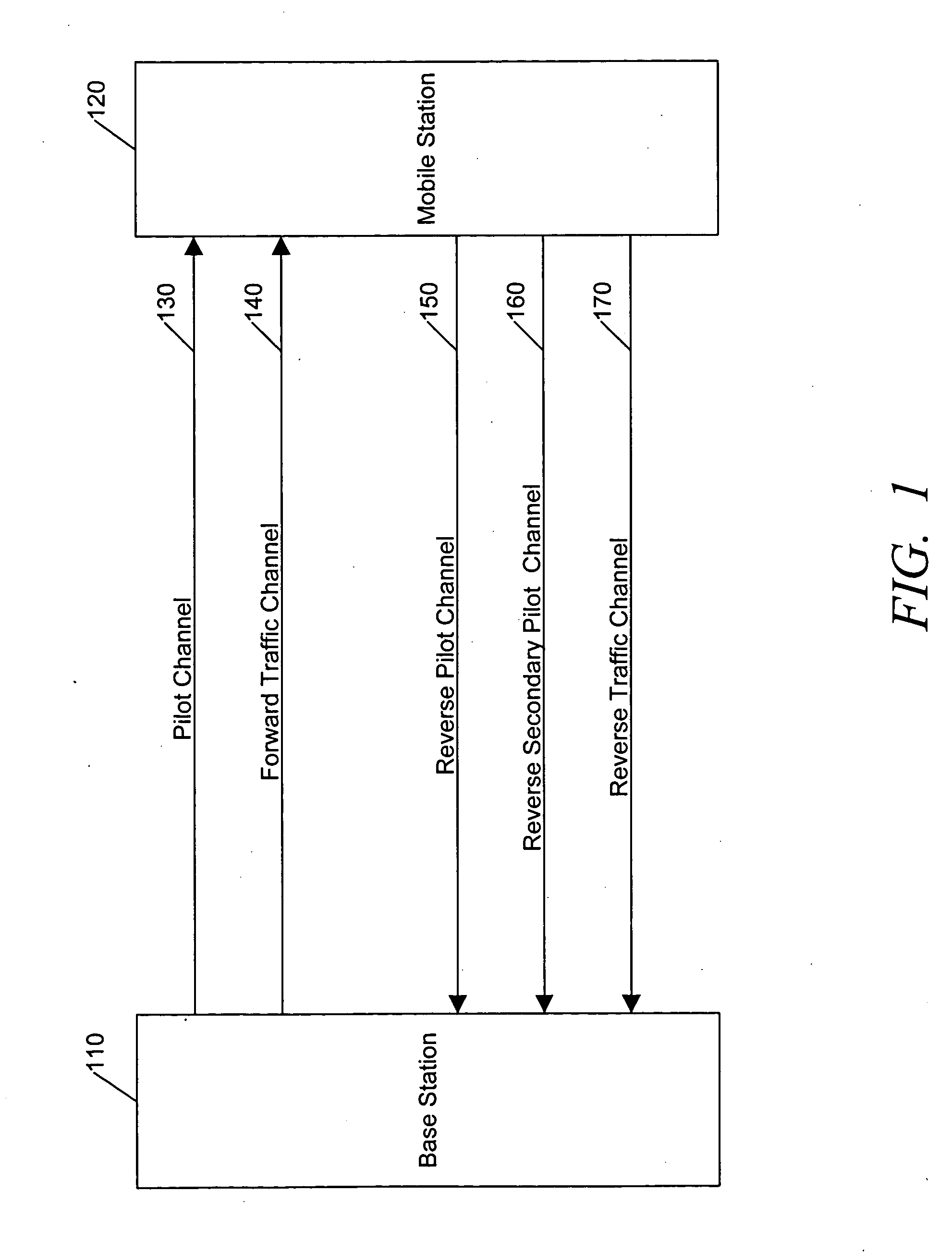

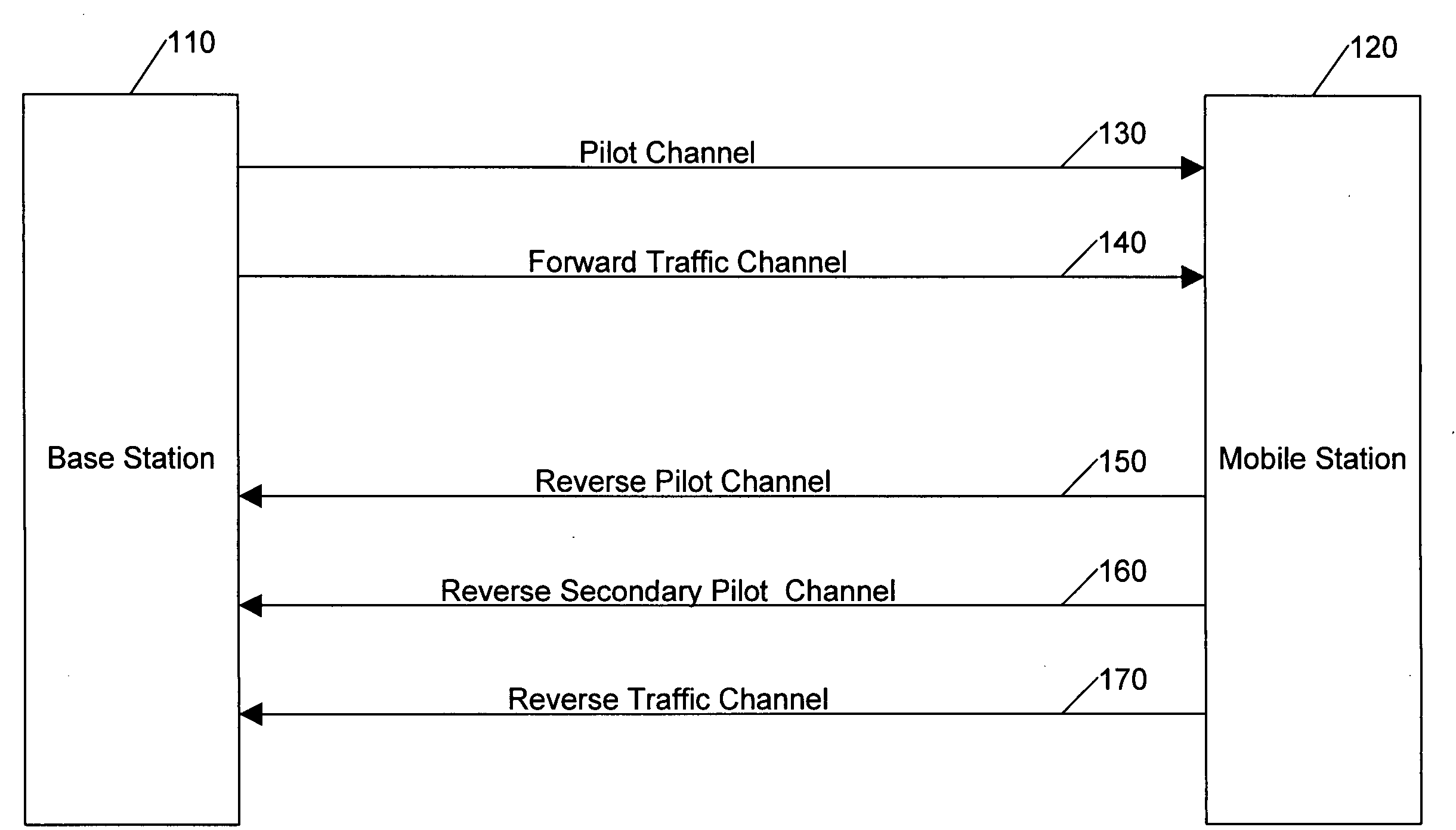

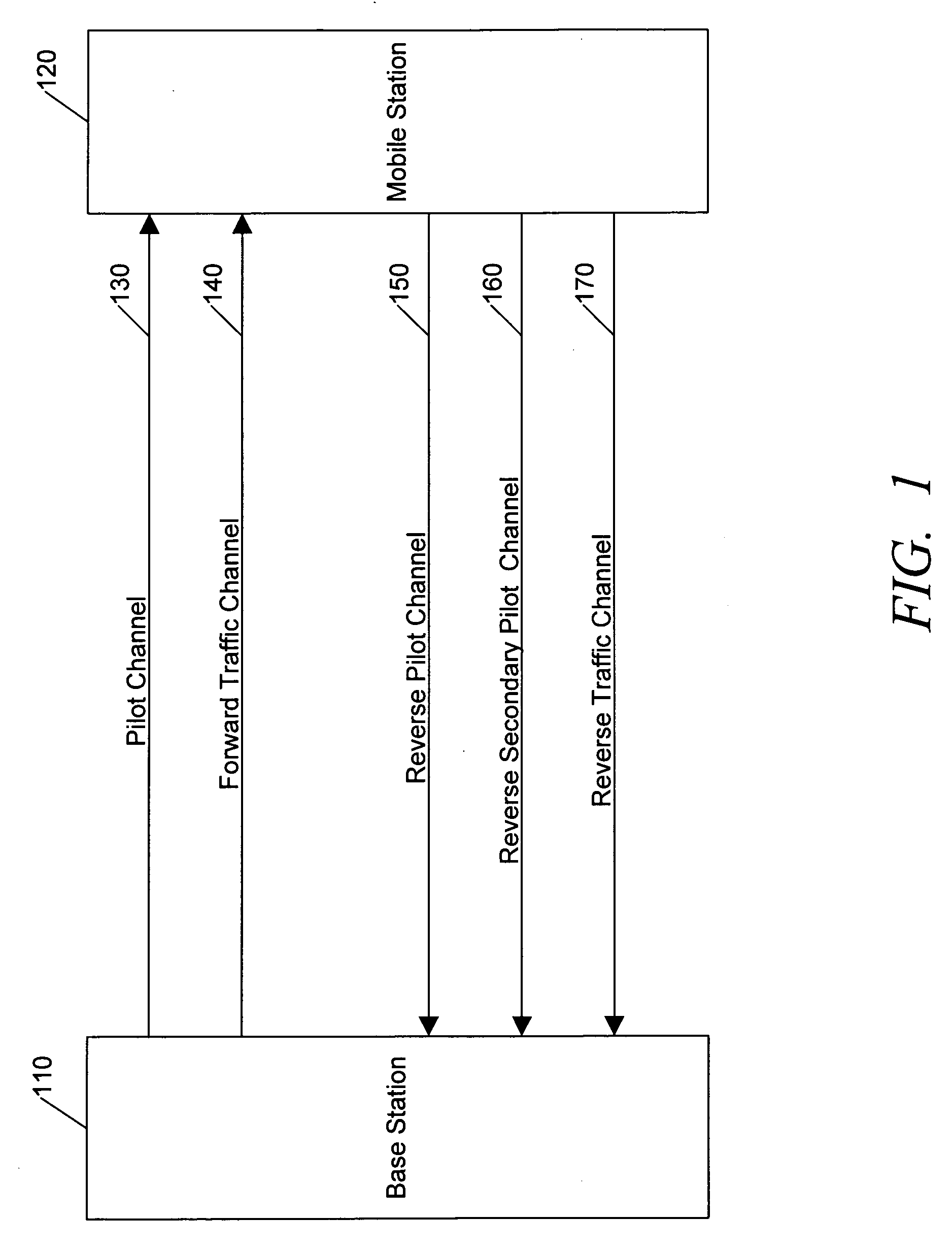

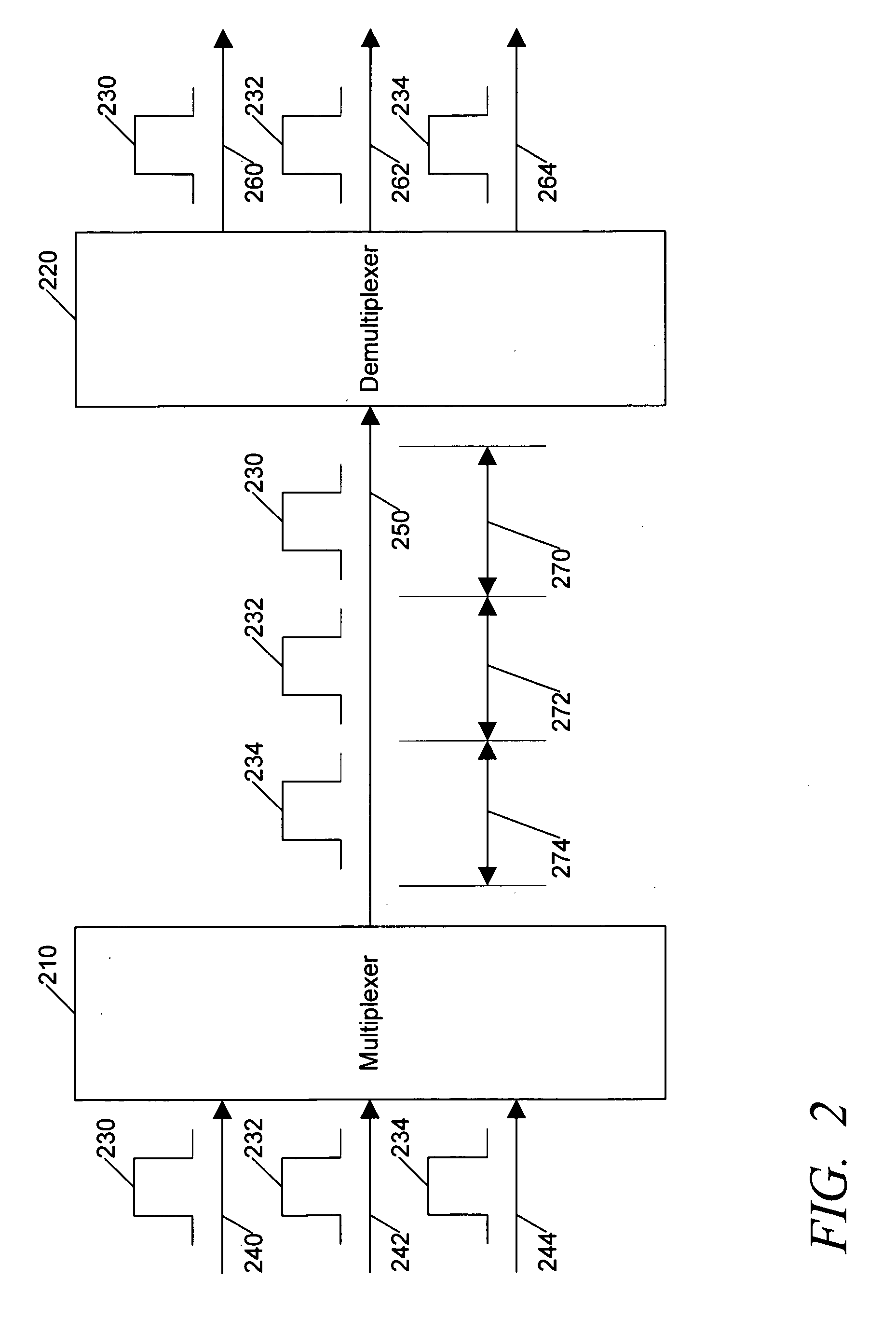

Pilot signal enhancements for a wireless communication system

ActiveUS20050030926A1Improve the usefulnessImprove effectivenessEnergy efficient ICTPower managementCommunications systemTraffic signal

In a method and apparatus suitable to convey timely information for facilitating accurate reception of transmitted data, a pilot signal is modulated to convey information. The information may facilitate efficient interpretation of an associated traffic signal. Modulation of a pilot signal frame may be limited to ensure early detection, and / or to minimize impairment of pilot functionality. In one embodiment, a Secondary Pilot Channel (SPICH) is transmitted at one of several selectable power levels to boost effectiveness of a phase reference, and is modulated to indicate the selected level. Such timely information enables prompt optimal combining of the SPICH with a primary Pilot Channel (PICH), and / or permits processing efficiencies for an associated traffic channel. Pilot signal frames may be transmitted at a predetermined level during a detection preamble portion of a frame to ensure accurate and early detection, and at a more optimal level thereafter.

Owner:APPLE INC

Communications systems and methods

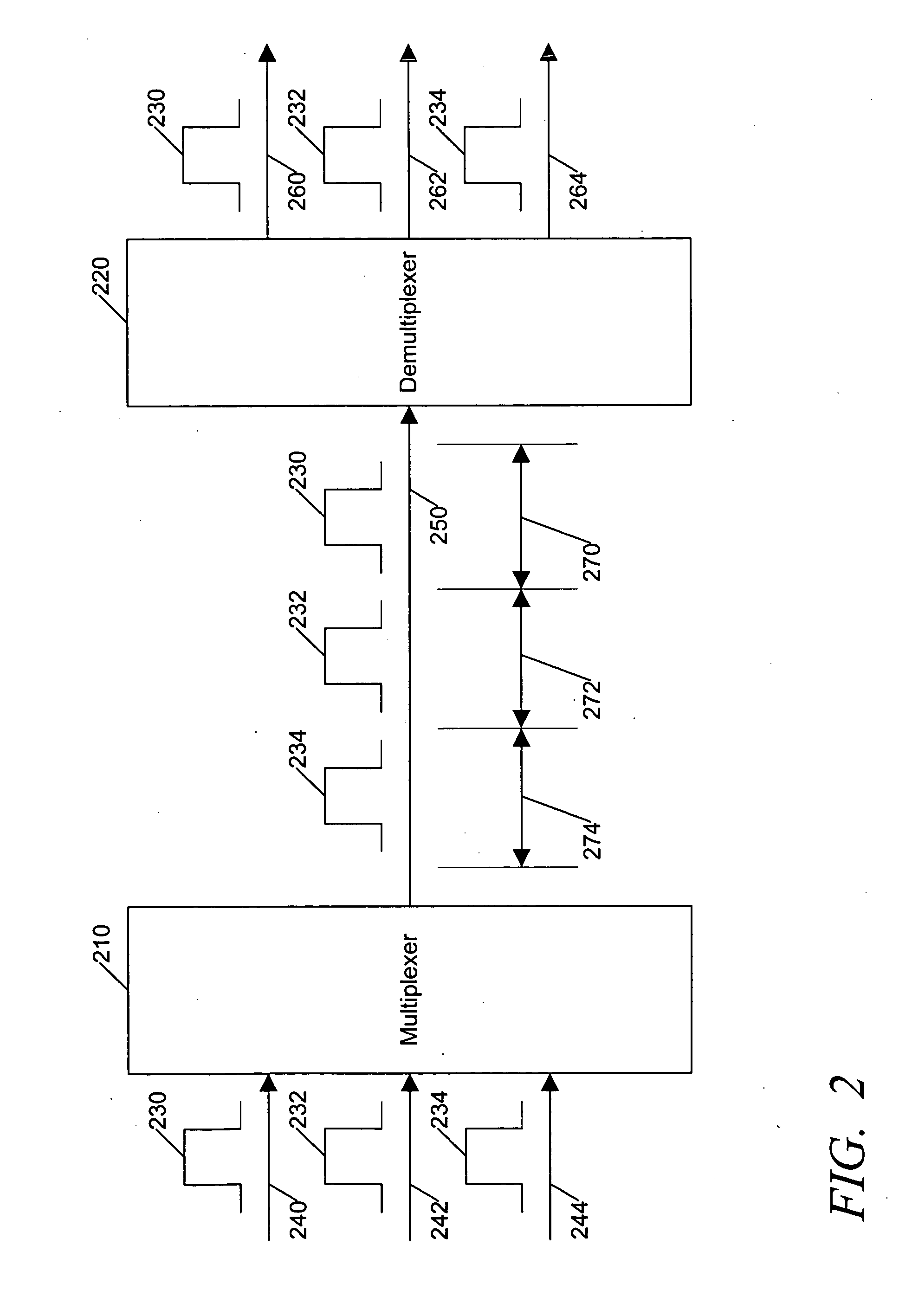

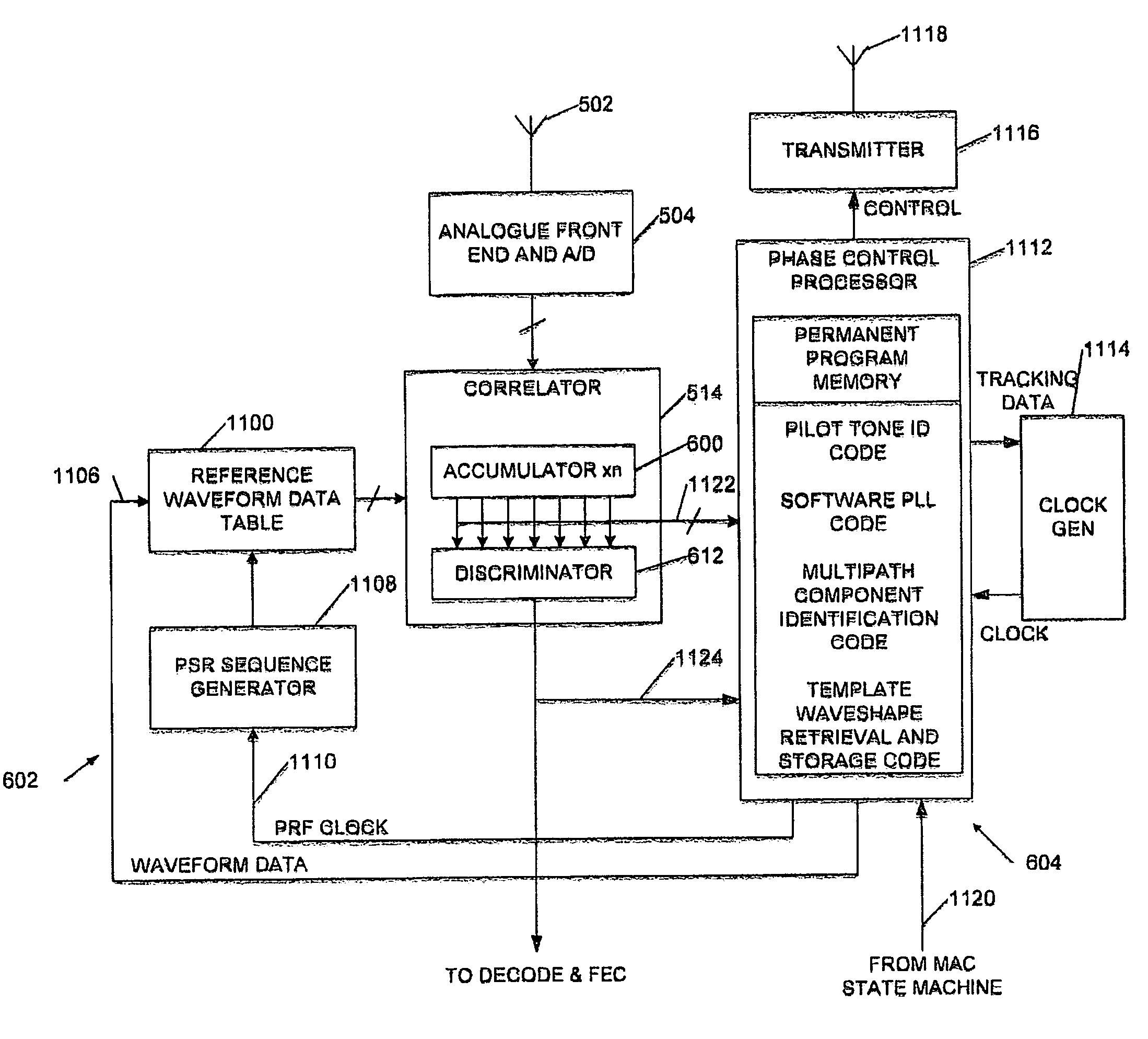

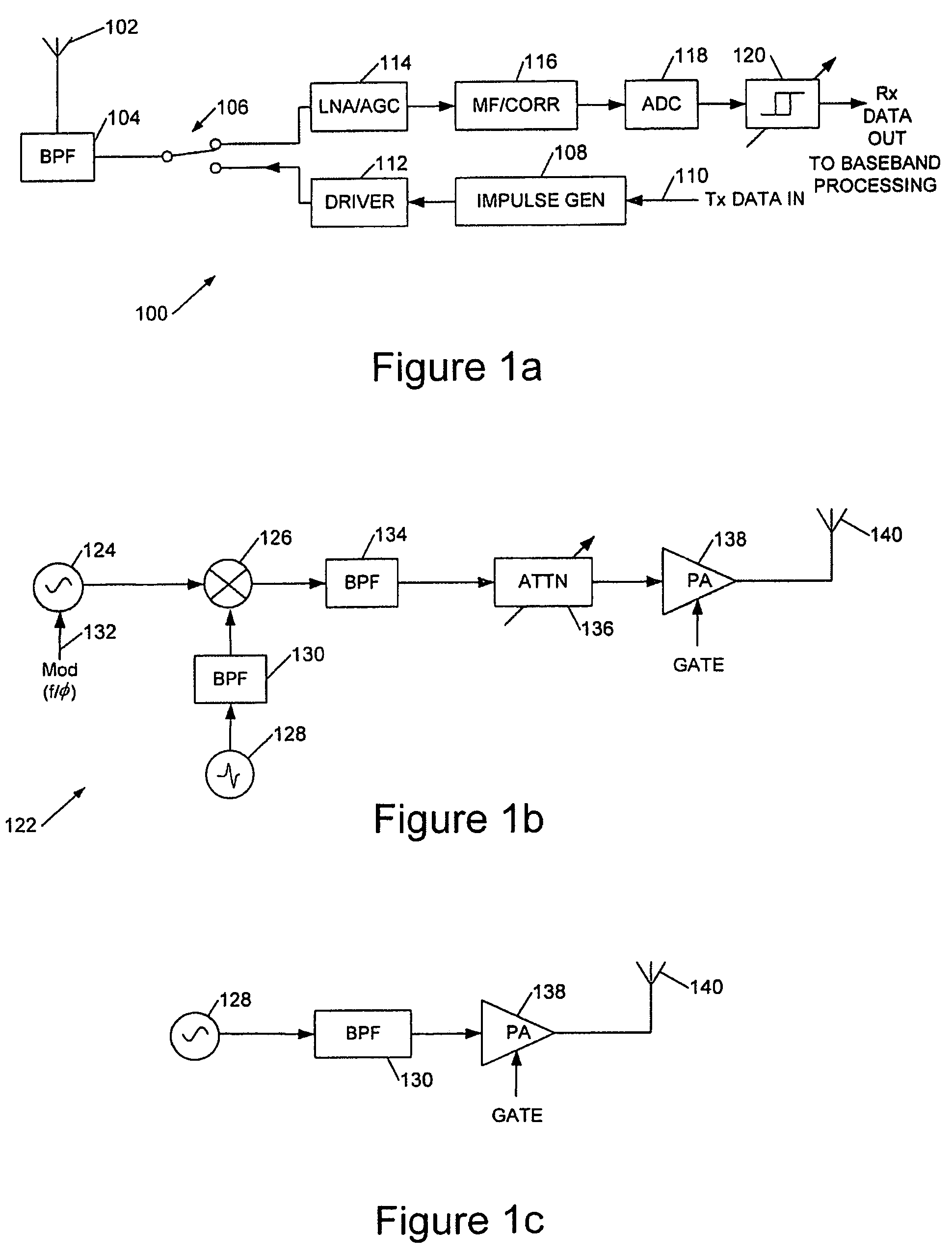

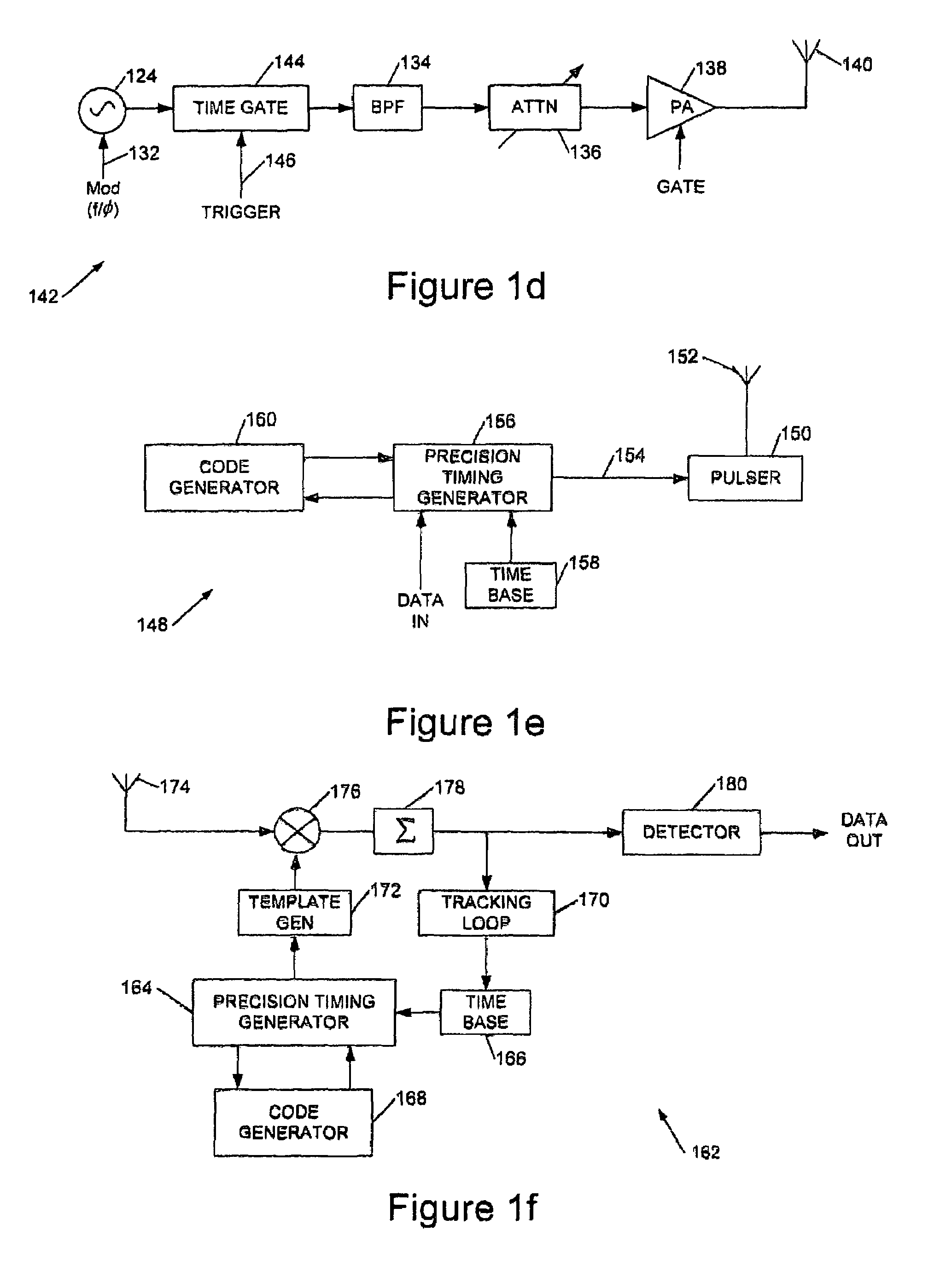

ActiveUS7457350B2Simple demodulationFrequency/rate-modulated pulse demodulationAmplitude-modulated carrier systemsUltra-widebandCommunications system

Described herein are ultra wideband (UWB) receiver systems, and applications thereof. Such a UWB receiver includes a receiver front end and a correlator coupled to the receiver front end. The receiver front end is configured to receive a UWB signal having a plurality of multipath components. The correlator is configured to correlate the UWB signal with a reference signal. The UWB signal includes a plurality of pulses, wherein each pulse has a plurality of multipath components. The reference signal also includes a plurality of multipath components of the pulse. The correlator includes at least one correlator module configured to correlate a plurality of the multipath components of the pulse with the reference signal.

Owner:TAHOE RES LTD +1

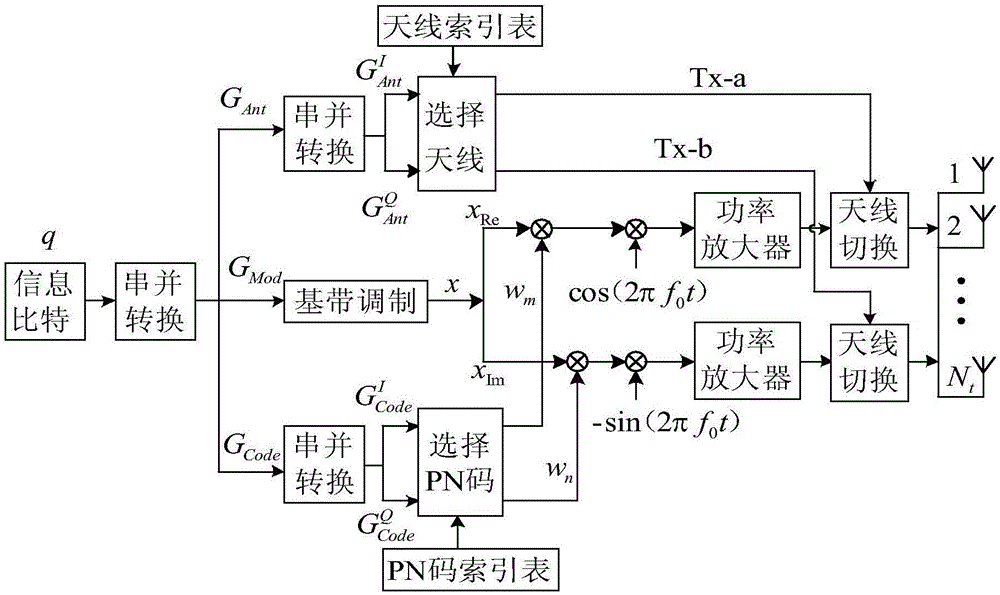

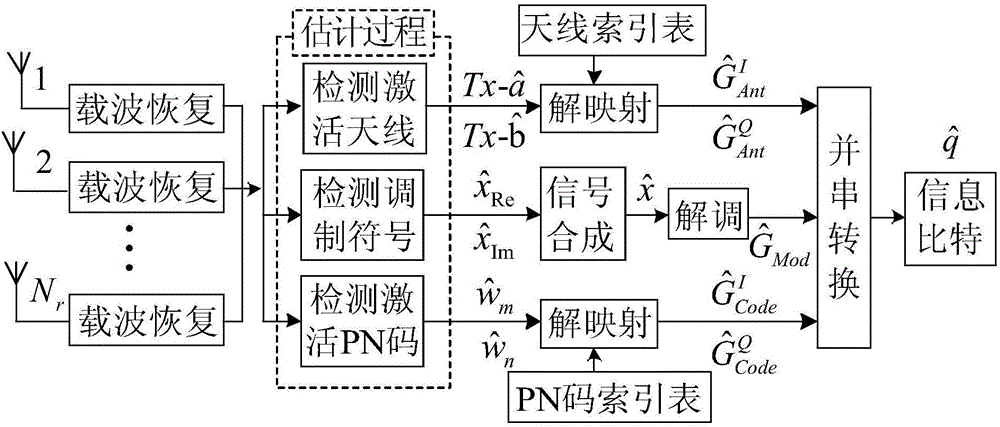

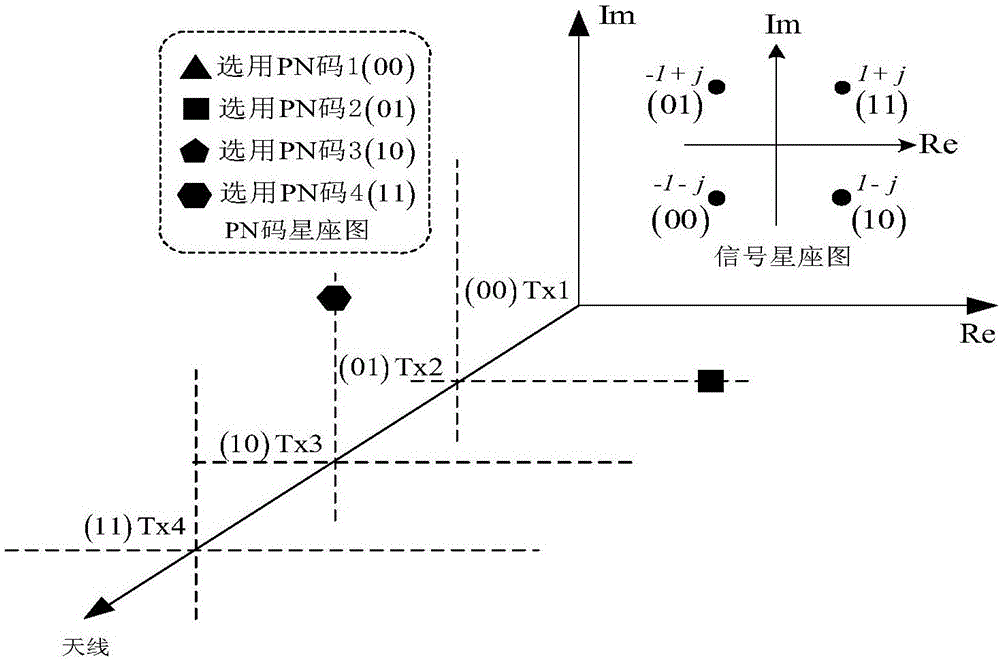

Space-code two-dimensional index modulation wireless communication system and method

InactiveCN106788636AReduced mapping constellation diagram dimensionsReduce consumptionRadio transmissionIndex mappingCommunications system

The invention discloses a space-code two-dimensional index modulation wireless communication system and method, and belongs to the technical field of wireless communication. According to a space-code two-dimensional index modulation scheme, two kinds of index resources are adopted for participating in indexing; a space index is combined with a code index; a transmission end is used for splitting an in-phase component and an orthogonal component of a baseband modulation symbol through a multi-antenna communication system mapped by the two-dimensional index; an orthogonal mapping way is adopted; independent index mapping is performed; a PN code required by current component frequency spread and an activated antenna are selected separately. When a receiving end detects information through a detection algorithm in an estimation way, information detection is performed according to an in-phase branch and an orthogonal branch of a signal. By adopting the space-code two-dimensional index modulation wireless communication system and method, a space modulation antenna indexing way is combined with a code index modulation indexing way, and an orthogonal mapping way is adopted, so that an antenna index and a code index are reutilized repeatedly, and information bits transmitted by index mapping are improved. The system frequency spectrum efficiency is increased, and the consumption of index resources is lowered.

Owner:CHONGQING LINFEI ELECTRONICS TECH CO LTD

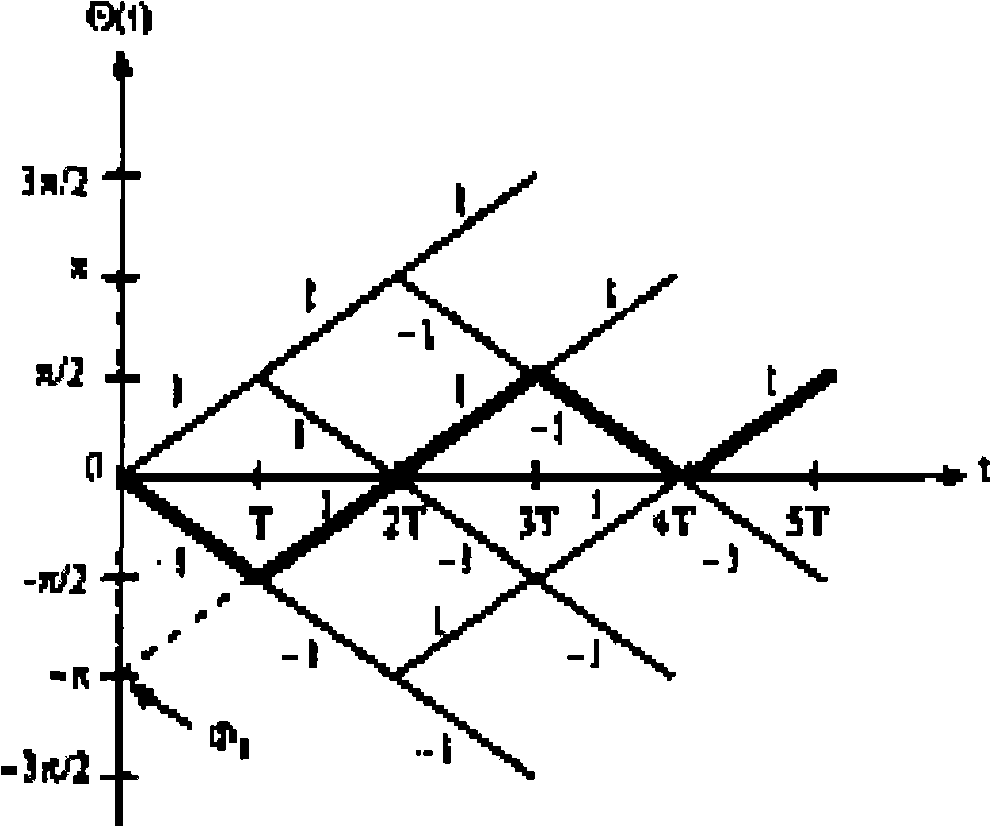

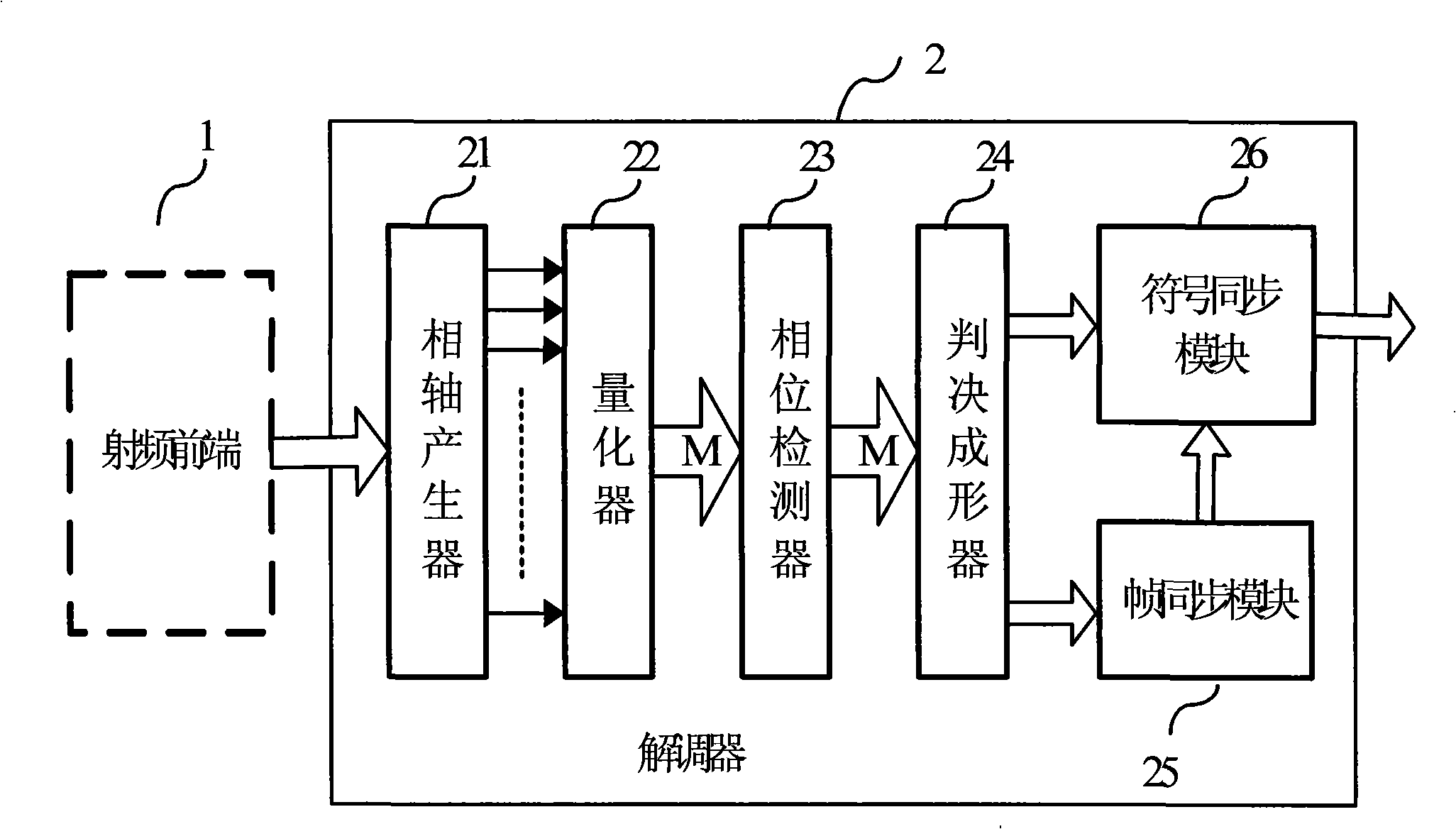

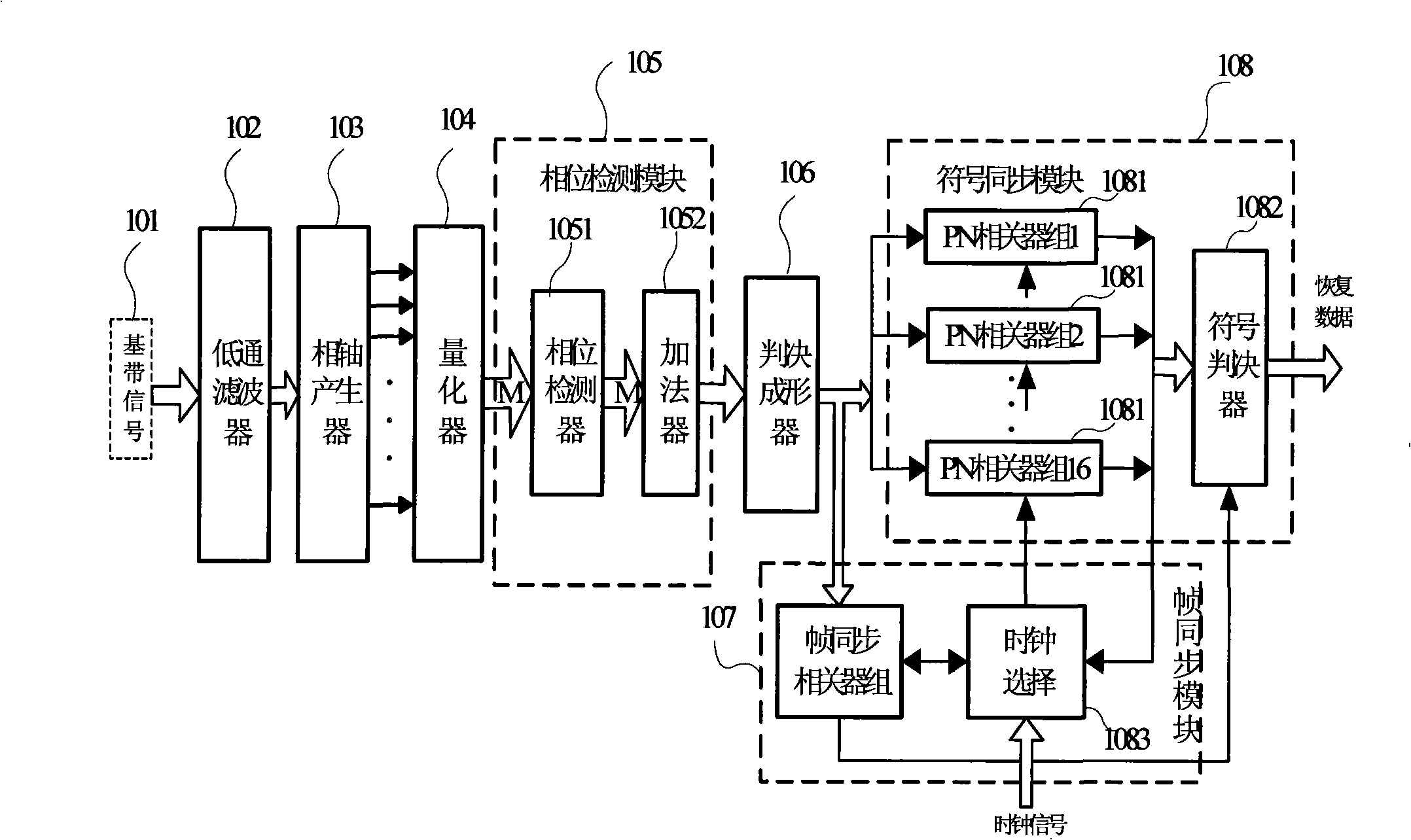

Low-power consumption MSK non-coherent digital demodulation method using phase axis detection and demodulator

InactiveCN101304396AReduce overheadReduce power consumptionModulated-carrier systemsEngineeringBaseband

The invention provides a low-power MSK non-coherent digital demodulating method by adopting the phase axis detection and a demodulator which consists of a phase axis generator, a quantizer, a phase detector, a judgment former, correlator groups, a sign judgment device and a clock selection circuit; wherein, the demodulator does not need an independent carrier frequency and a phase restoration circuit or a data restoration clock circuit; DSSS signals can directly de-spread by adopting the correlator groups without a clock and bit restoration circuit; the algorithm of the slopes of phase changes of base-band signals of PN code sequence is adopted in relative judgments, which can overcome the phase cumulative errors caused by the random clock skew of a sending terminal; in addition, the demodulator has a better compensation ability for frequency errors without special frequency compensation circuits; furthermore, the demodulating performance is unrelated with carrier phases and the synchronization performance of DSSS frequency spread and frames and signs is good. The MSK demodulator is characterized by simple demodulating method, low packet loss rate, few hardware expenses, strong anti-noise ability, low power, easy integration, and the like, and can be applied to modern high-end communication terminals.

Owner:杭州中科微电子有限公司

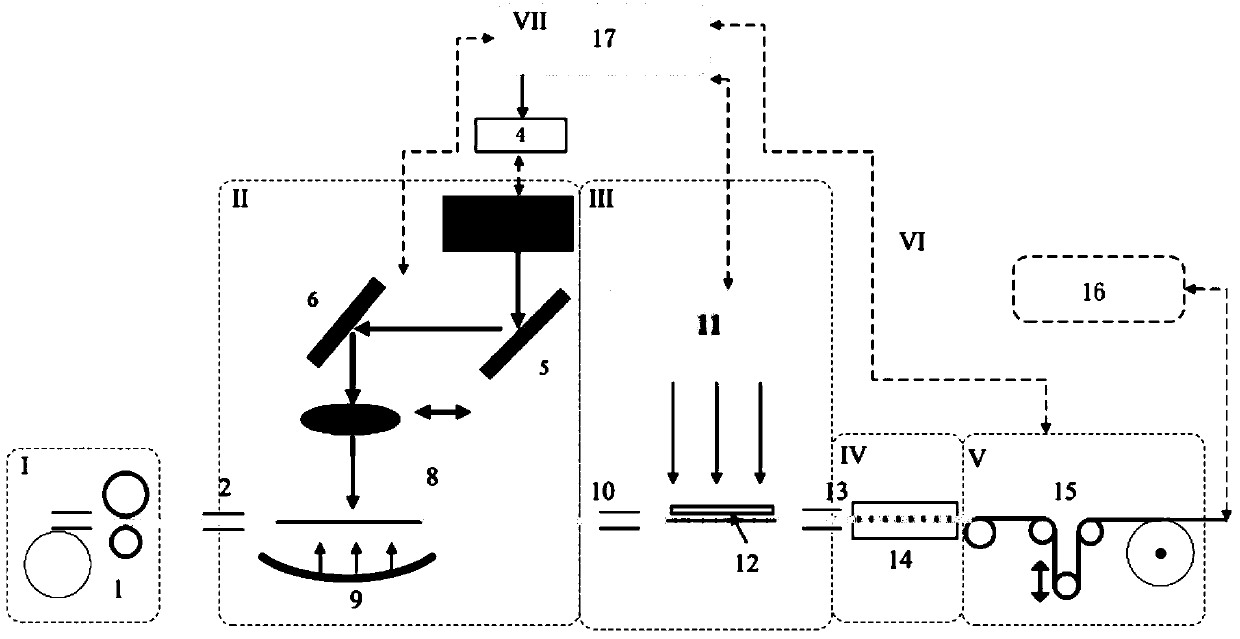

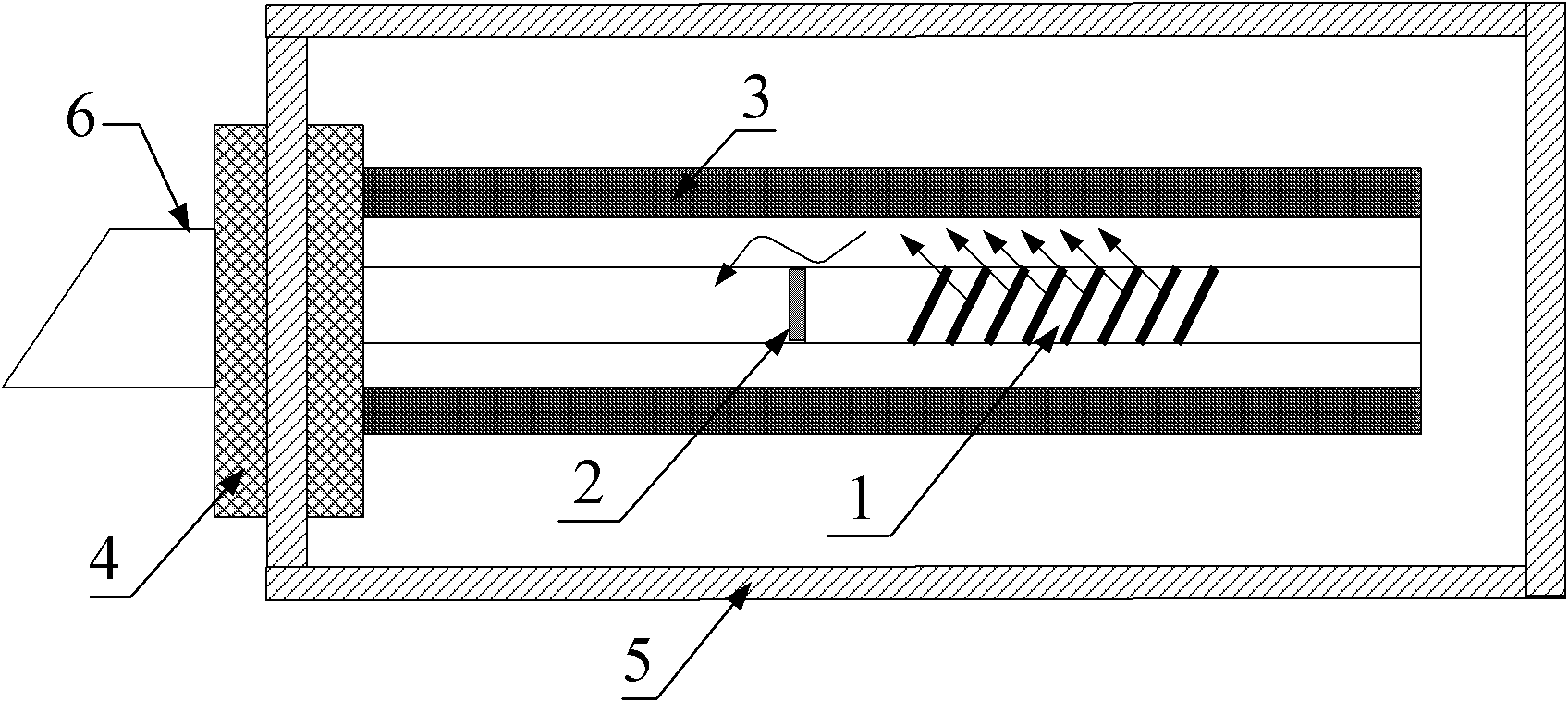

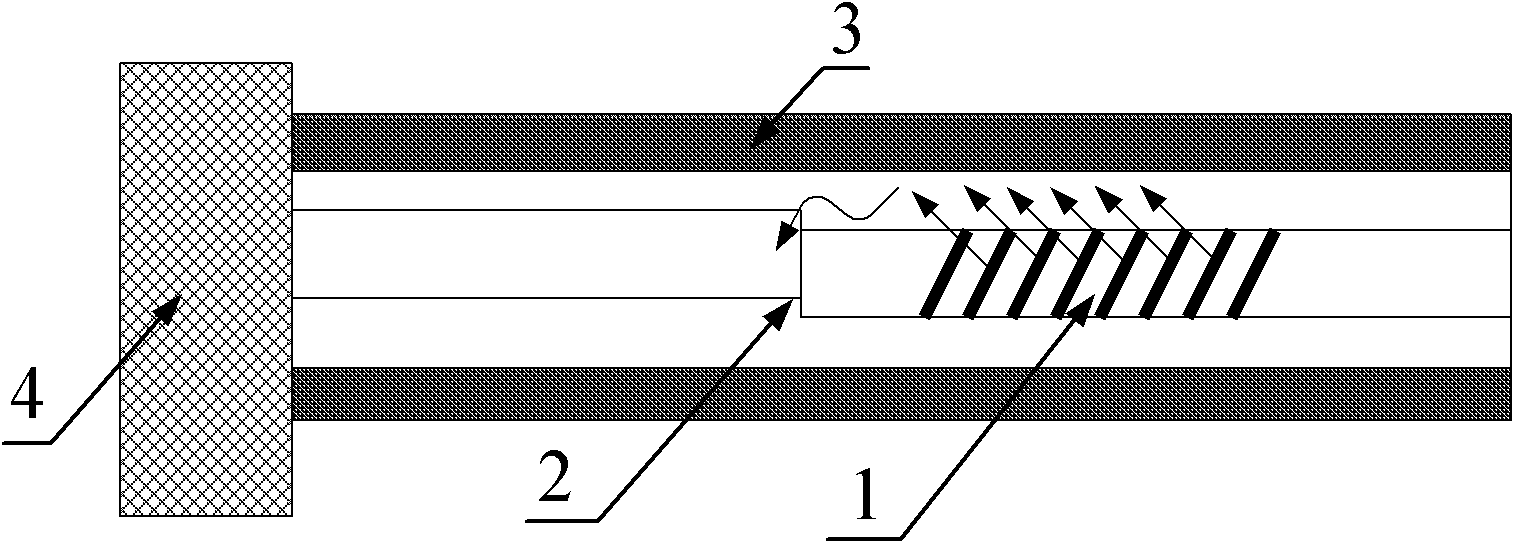

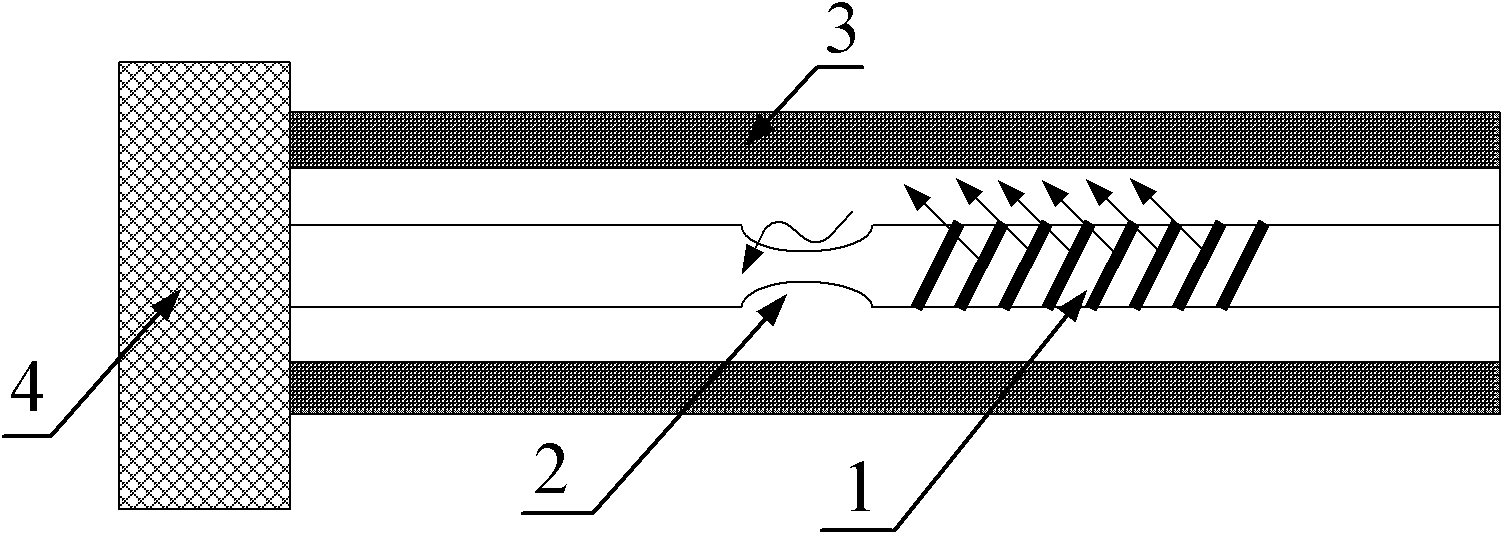

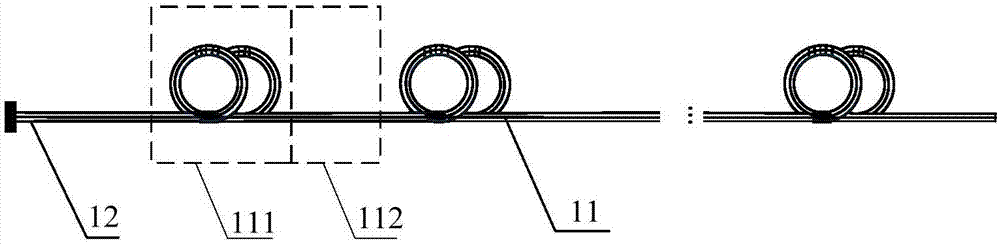

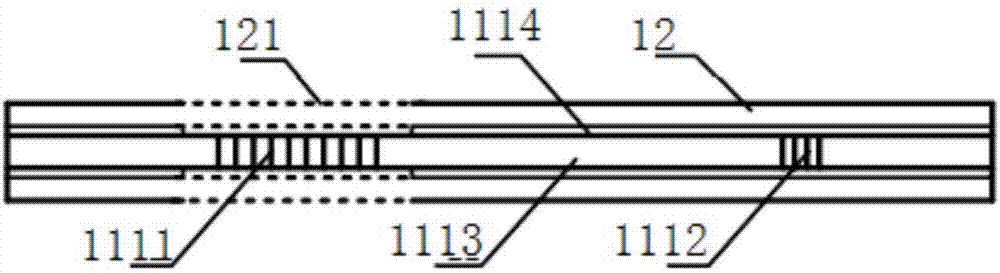

Device and method for automatic, static continuous preparation of fiber bragg grating array

InactiveCN103777270ASmall absorption coefficientPrecision stepping movement speedCladded optical fibreOptical waveguide light guideFiberGrating

A device for automatic, static continuous preparation of a fiber bragg grating array comprises an optical fiber paying-off module, a coating layer stripping module, an optical grating inscribing module, a coating module and a fiber winding module, wherein the optical fiber paying-off module, the coating layer stripping module, the optical grating inscribing module, the coating module and the fiber winding module are sequentially arranged in the optical fiber running direction. The optical fiber paying-off module comprises a coiling drum. The coating layer stripping module comprises a CO2 pulse laser, a first reflector, a second reflector, a focusing lens and a cylindrical surface reflector arranged in sequence. The optical grating inscribing module comprises an excimer laser and a phase mask plate. The coating module comprises an automatic ultraviolet light coating device. The fiber winding module comprises an automatic fiber winding device. A method for automatic, static continuous preparation of the fiber bragg grating array aims at non-hydrogen-loaded common fibers, and in the optical fiber paying-off and winding process, the method includes the first step of partially stripping coating layers of fibers through narrow-pulse infrared light, the second step of moving optical fiber portions of the stripped coating layers to the excimer laser for inscribing, the third step of moving the optical fiber portions after being inscribed to the ultraviolet light coating device for ultraviolet light coating and curing, and the fourth step of repeating the first step to the third step to carry out inscribing on multiple fiber bragg gratings to form the fiber bragg grating array.

Owner:WUHAN UNIV OF TECH +1

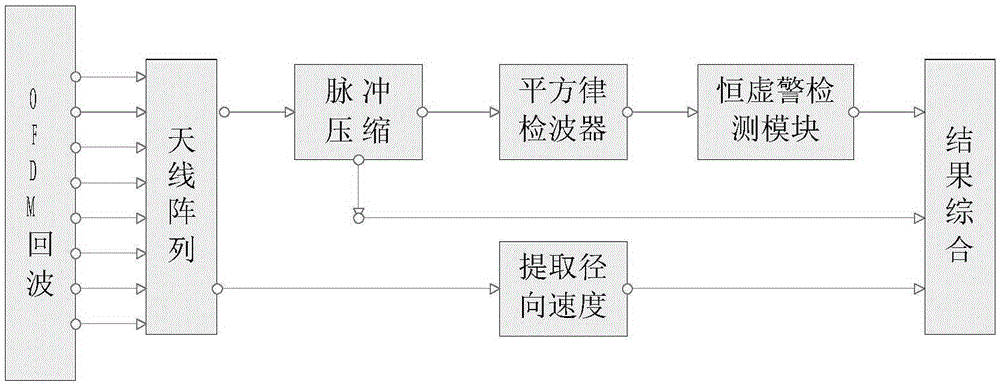

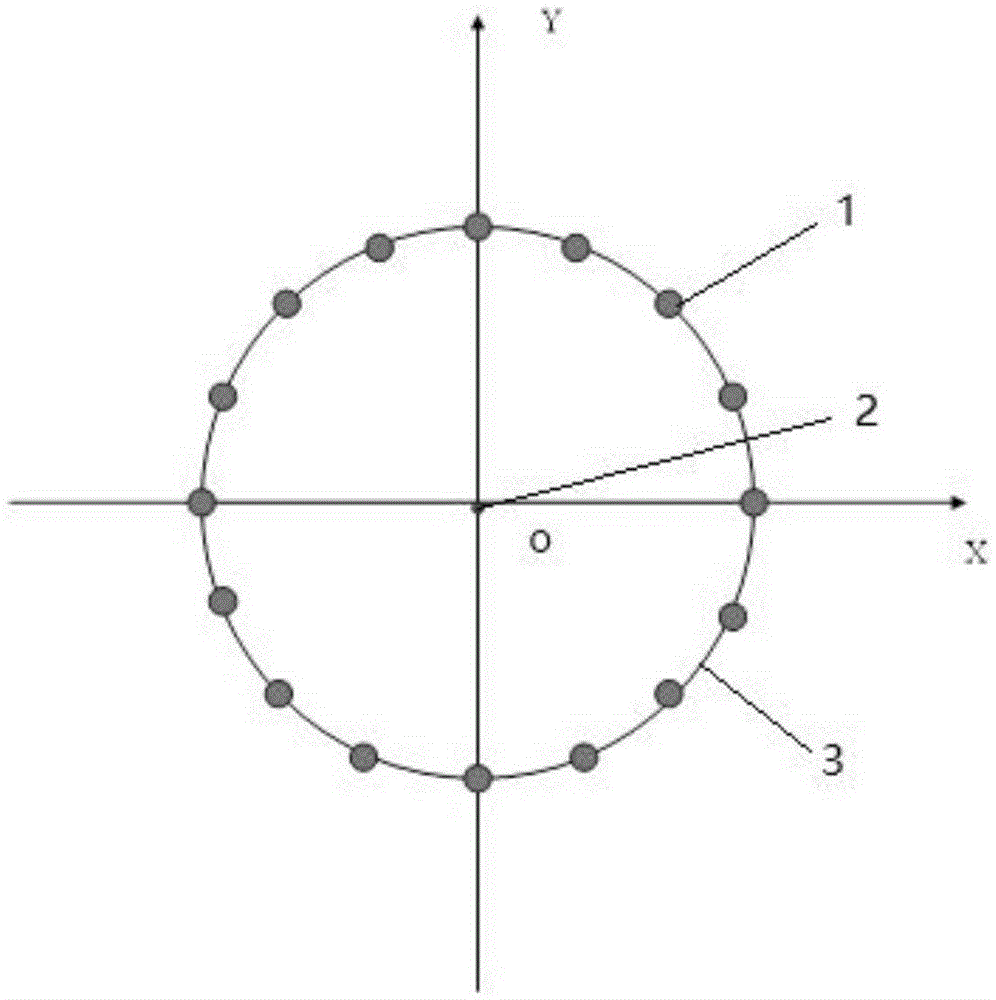

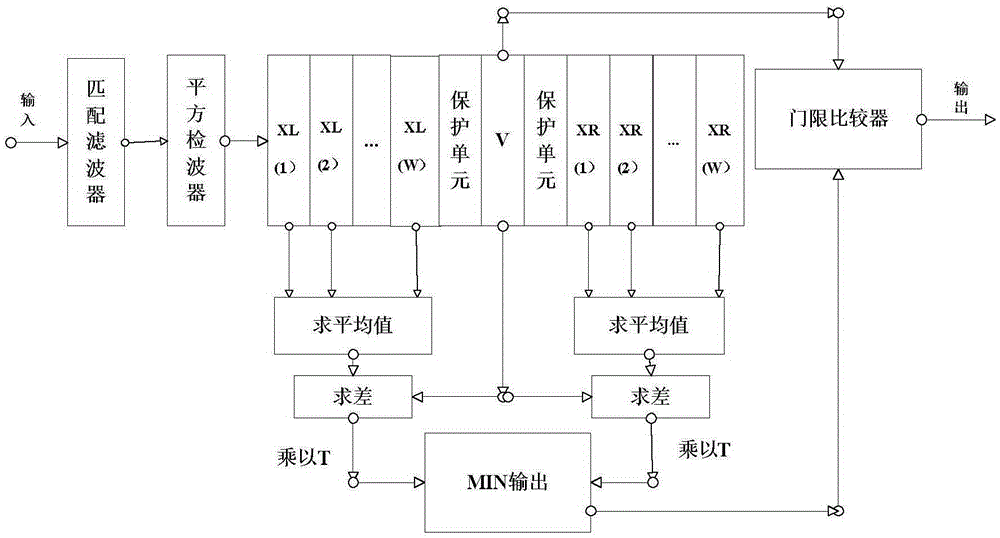

Passive radar low-altitude object detection method

ActiveCN105425225AWide coverageSimple demodulationWave based measurement systemsLow noisePassive radar

The invention provides a passive radar low-altitude object detection method. The distance between an object and an array is detected by installing a circular passive receiving radar antenna array, receiving OFDM communication signals reflected by a low-altitude slow-speed object and performing pulse compression, then a weak object under a low signal-to-noise ratio and strong interference is detected through a constant false alarm detection module, and finally, determination and advanced early warning of a low-altitude object with a potential threat are carried out through extracting the speed of the detected weak object. The method provided by the invention decreases the cost under the condition that the coverage scope is ensured by use of OFDM wireless communication signals through a passive radar system, and compared to a conventional OFDM phase-coded radar, is greatly simplified in terms of system; and the method is suitable for application in key areas which are covered by the OFDM wireless communication signals and require monitoring of low-altitude safety by use of such features of high utilization rate of an OFDM signal spectrum, good anti-multipath performance, high-distance resolution with broadband, adaptability of narrowband to a low noise-to-signal ratio and the like.

Owner:NAT UNIV OF DEFENSE TECH

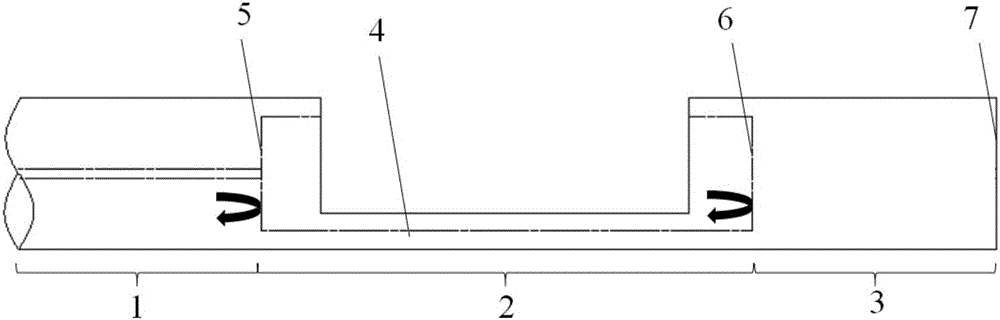

Micro nano fiber vibration sensor based on hollow fiber

ActiveCN106124027AReduce volumeGood quality interference signalSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectromagnetic interferenceResonance

The invention relates to a micro nano fiber vibration sensor based on a hollow fiber and belongs to the field of fiber sensing. A single-mode fiber, a hollow fiber and a solid core fiber are welded in sequence. The hollow fiber is a hollow cylindrical column. The center of the side surface of the circular column is provided with a groove, and the length in the axial direction of the groove needs to be smaller than the length of the hollow cylindrical column. The groove is formed by burning the side surface of the hollow fiber with a femto second laser. The invention solves the problem that a reflective surface formed when processing the fiber with the femto second laser has a low reflectivity or does not have a reflectivity; and the micro nano fiber vibration sensor is featured by small size, high resonance frequency, high temperature resistance, electromagnetic interference resistance and the like, and can be used for vibration measurement in high temperature environments.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

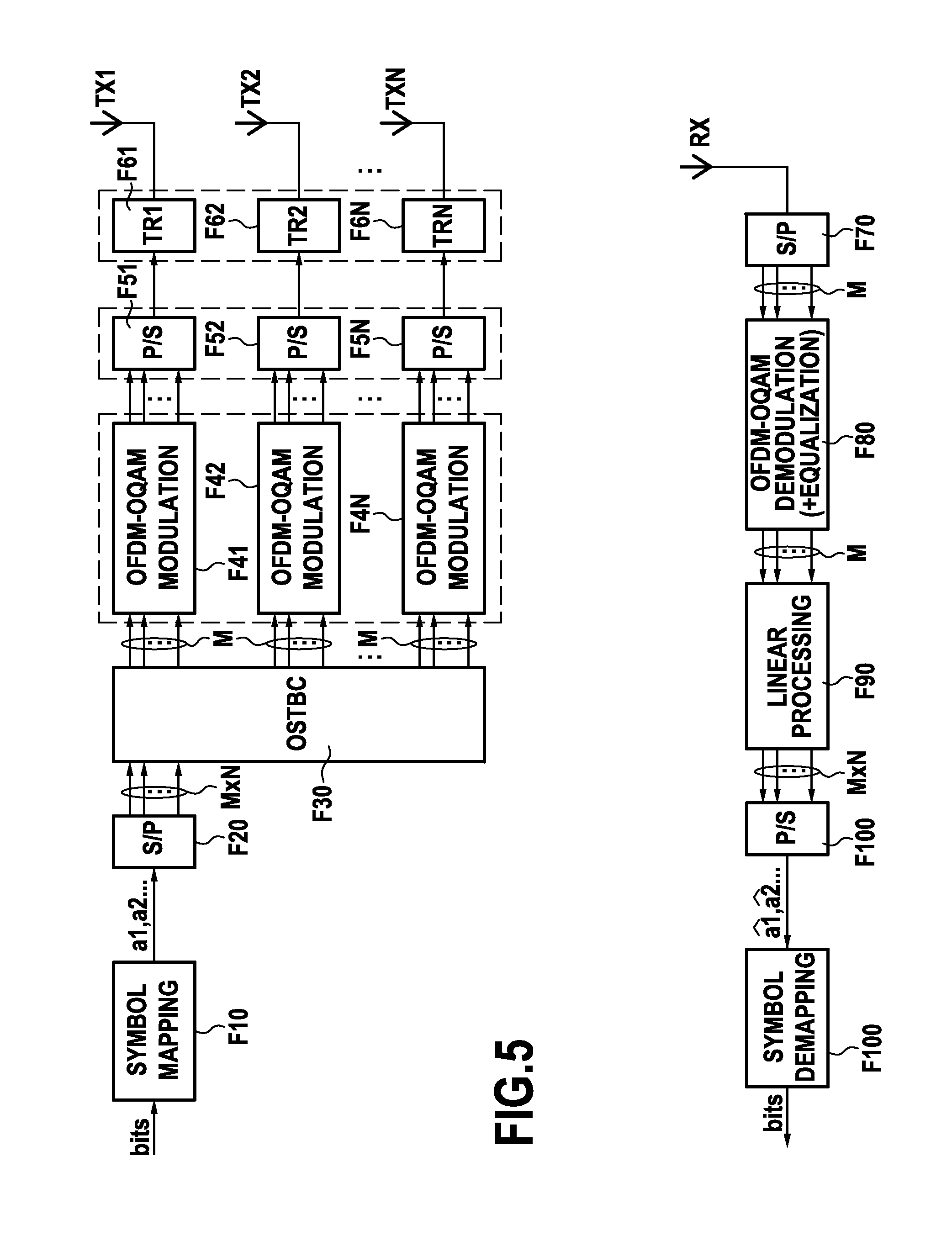

Method for transmitting at least one multi-carrier signal consisting of OFDM-OQAM symbols

ActiveUS9479381B2Avoid it happening againMaximize Spectral EfficiencySpatial transmit diversityFrequency-modulated carrier systemsTransmission channelMulti carrier

Disclosed is a transmission method of transmitting at least one multicarrier signal made up of OFDM-OQAM symbols to a receive antenna of a receiver device, the transmission method being for use by a transmitter device having at least one transmit antenna. In one embodiment, the method comprises, for each transmit antenna of the transmitter device, filtering OFDM-OQAM symbols associated with the transmit antenna using a time-reversal prefilter defined from an estimate of the transmission channel between the transmit antenna and the receive antenna and transmitting the filtered OFDM-OQAM symbols via the transmit antenna over the transmission channel.

Owner:ORANGE SA (FR)

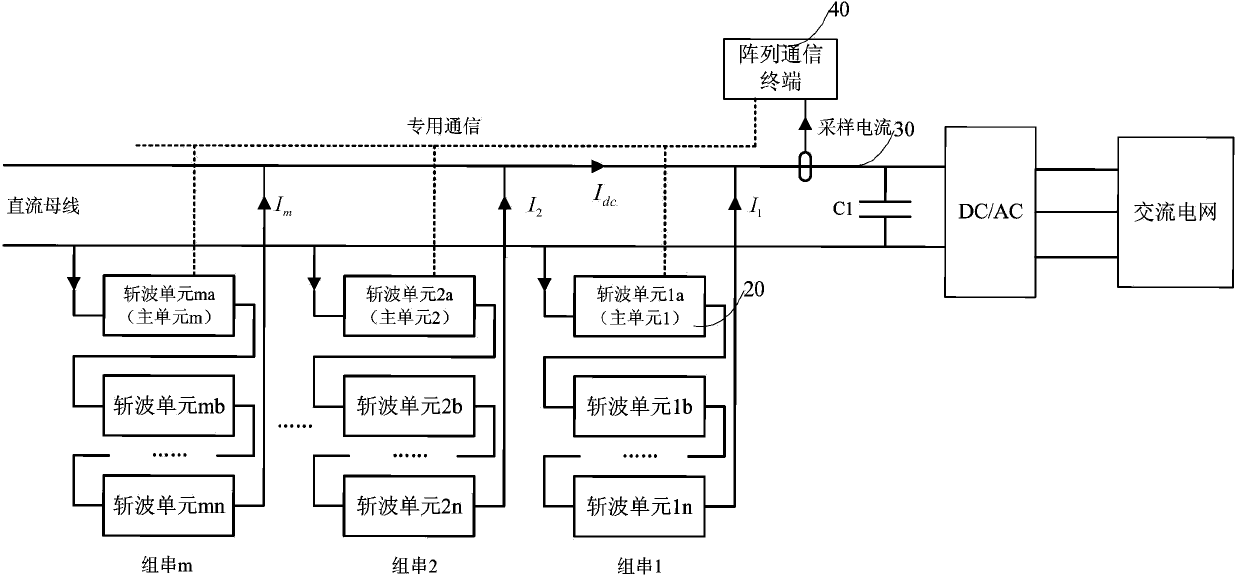

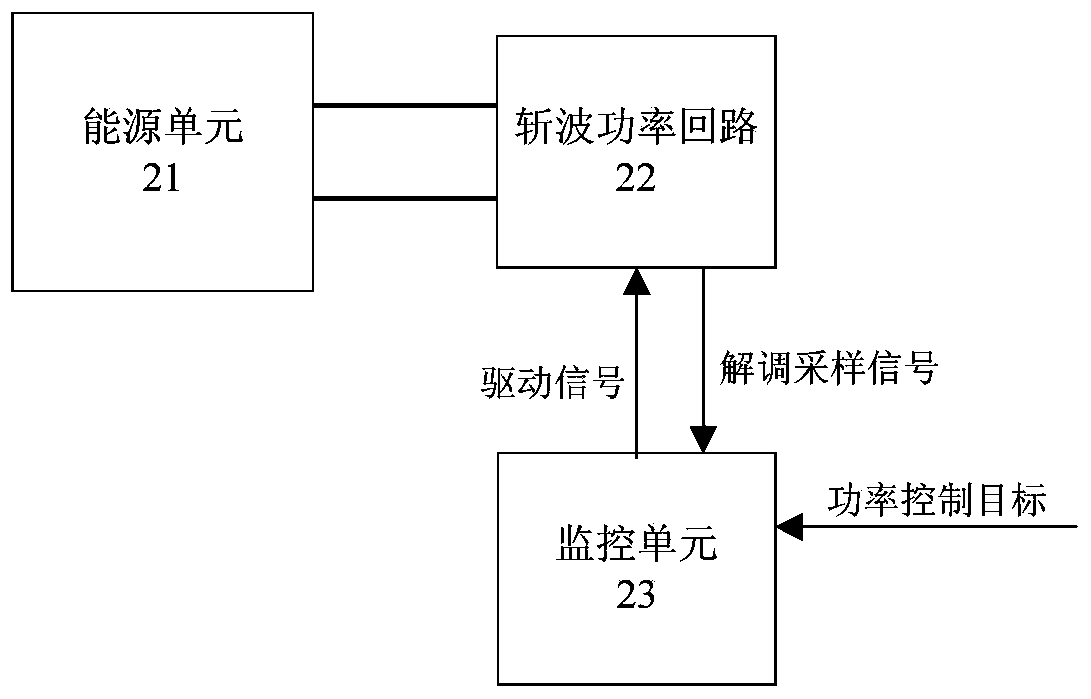

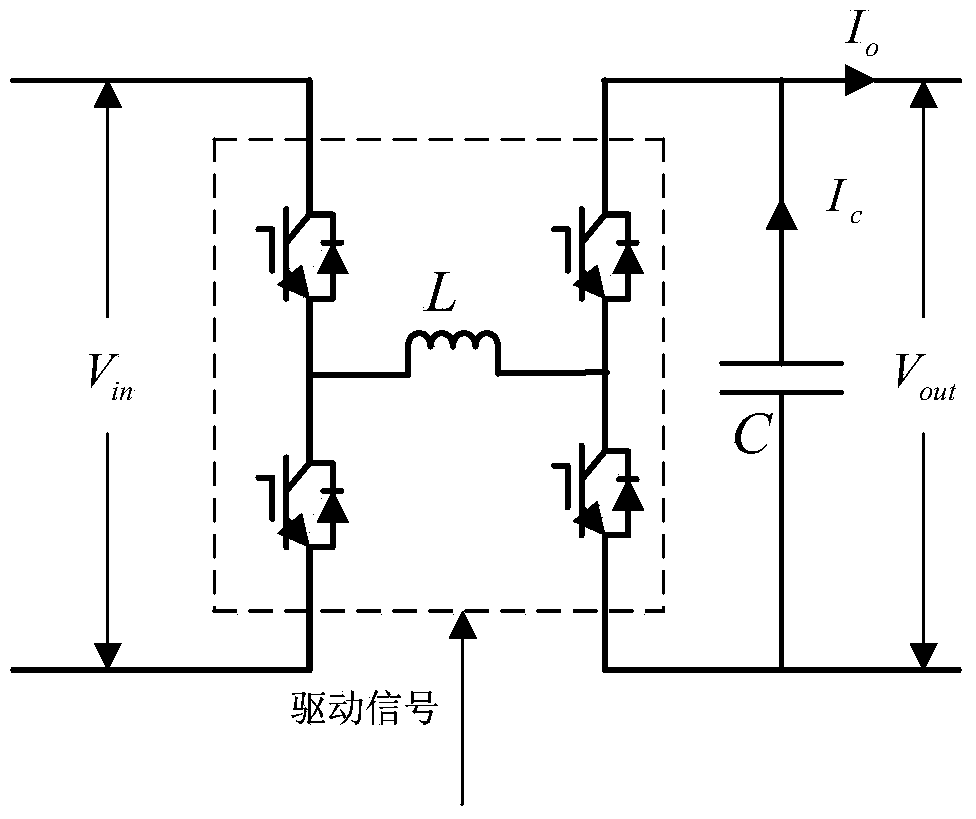

Method and apparatus for realizing composite communication of power and communication signals in electric power system

InactiveCN104184492ARealize two-way communication functionAvoid high-frequency filteringPower distribution line transmissionCapacitanceElectric power system

The invention relates to the technical field of communication of electric power devices and electronic devices, and provides a method and apparatus for realizing composite communication of power and communication signals in an electric power system. The method comprises the following steps: modulating source signals by reference to an FSK modulation mode, and generating PWM signals after composite modulation of the source signals and power by use of a PWM technology, wherein the PWM signals are transmitted in the form of data frames, and the data frames comprise a sender address, a destination address and data information; sampling DC bus currents, and obtaining the source signals sent to an array communication terminal through demodulation and reduction; and sampling capacitance branch currents of a chopper power loop, and obtaining the source signals sent to a chopper unit through demodulation and reduction. According to the invention, the PWM pulse signals generated by use of the PWM mode are taken as carriers for composite transmission of the source signals and the power, demodulation is carried out through detecting current signals in a line, and the corresponding source signals are obtained through reduction, such that composite transmission of the power and signals is quite well realized.

Owner:CHINA AGRI UNIV

fiber optic geophone

InactiveCN102262241AHigh sensitivityDemodulation is simpleCladded optical fibreSeismic signal receiversOpto electronicPhotodetection

The invention discloses an optical fiber geophone, which comprises a tilted optical fiber grating, a cladding-core energy recoupling structure, a polymer elastic tube, a supporting member, a shell and an optical fiber wire. One end of the polymer elastic tube is fixed on the supporting member. The other end is suspended to sense vibration, and the tilted fiber grating and cladding-core energy recoupling structure are all encapsulated in a polymer elastic tube; the outer side of the polymer elastic tube is protected by a shell, and the polymer elastic tube communicates with an external light source and photoelectric detection through an optical fiber wire The cladding-core energy recoupling structure is processed by a dislocation fusion splicing method or a fiber tapering method. The invention adopts a cladding-fiber core energy recoupling structure, which has a compact structure, and the structure is very sensitive to optical fiber micro-bending or optical fiber vibration, has high sensitivity, and the device demodulation is simpler and the demodulation cost is low.

Owner:JINAN UNIVERSITY

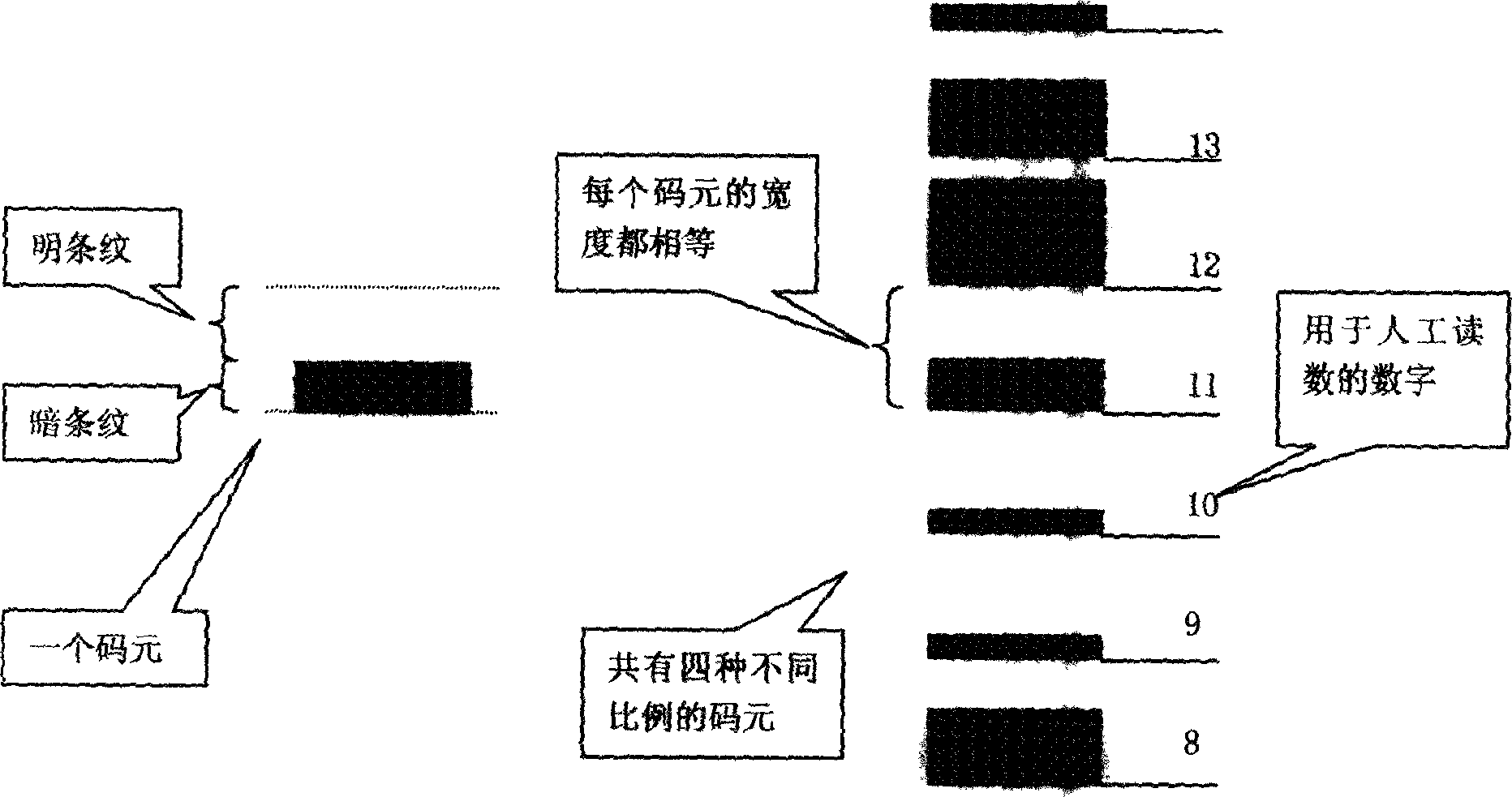

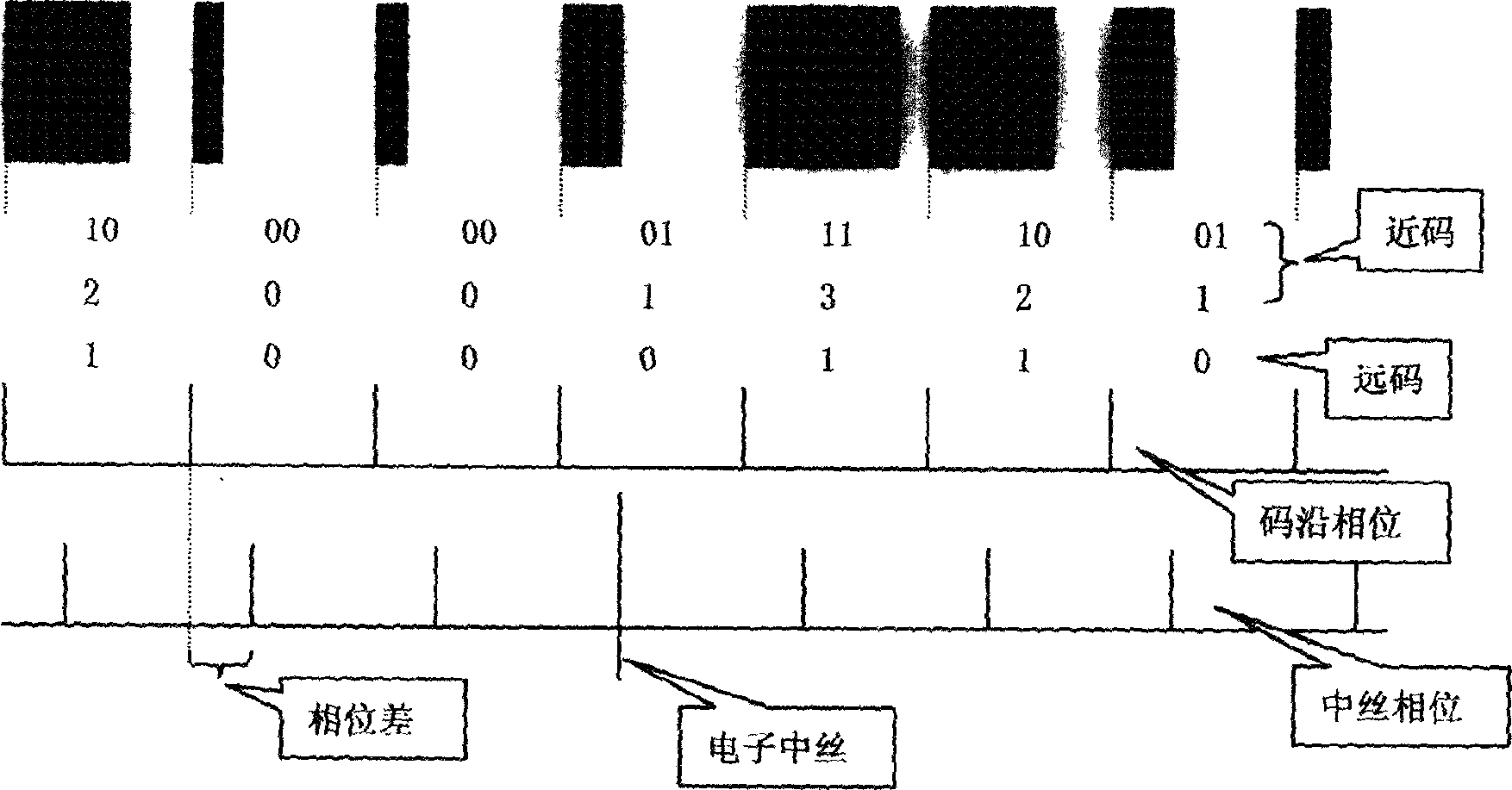

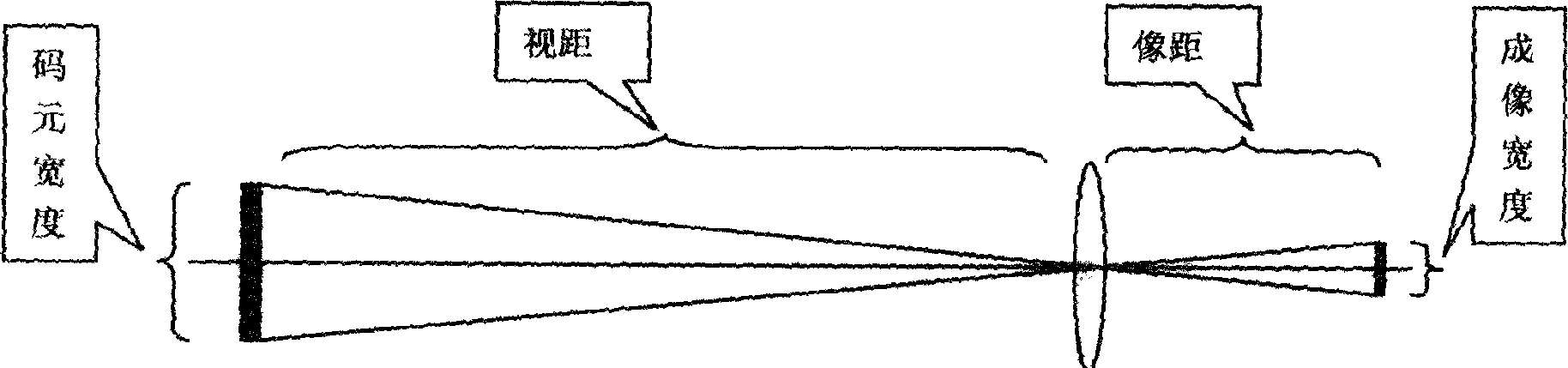

Bar code for digital level bar code ruler and electronic theodolite dial and encoding and decoding method therefor

InactiveCN1632464ASimple demodulationEasy to checkSurveyor's staffsMovable markersDecoding methodsEngineering

This invention relates to bar code used in digit water level code bar and electrical theodolite panel and its coding and decoding method. Its code elements are composed of a pair of light and dark strips with same order. The duty cycle of dark strips in the code elements at least two kinds and the code element with different duty cycle is named as proportion code. The multiple codes distributes as designed order to form the codes of digit water level and electrical theodolite panel which are characterized by the same width of each code element.

Owner:WUHAN UNIV +1

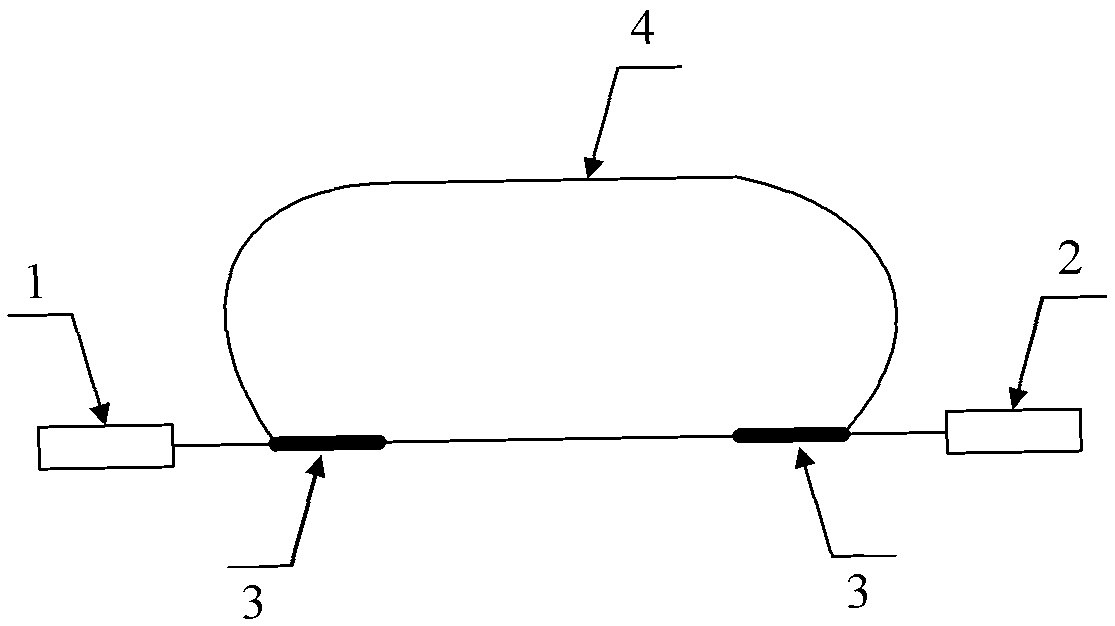

Multi-parameter sensor and measurement system based on photonic crystal fiber

InactiveCN101871791AHigh measurement accuracyHigh precisionCladded optical fibreOptical waveguide light guideEngineeringMeasurement precision

The invention discloses a multi-parameter sensor based on a photonic crystal fiber. An input end and an output end of the sensor are respectively provided with an input coupler and an output coupler, an annular photonic crystal fiber cavity is formed in the way that a section of hollow photonic crystal fiber is connected between the two couplers, and the section of hollow photonic crystal fiber is used as a sensing head of the multi-parameter sensor. The invention also discloses a multi-parameter measurement system which comprises a signal acquiring, processing and displaying module and the multi-parameter sensor, the sensor is respectively connected with a light source and a photoelectric detector through the input coupler and the output coupler thereof, and the photoelectric detector is connected to the signal acquiring, processing and displaying module. The invention additionally provides a pressure measurement system comprising the multi-parameter measurement system and a pressurizing device arranged on the sensing head, and the pressuring device comprises a plenum chamber, a photonic crystal fiber clamp, a connector and the like. The multi-parameter sensor and measurement system of the invention has the advantages of simple and convenient operation, simplified structure, high measurement precision, easy miniaturization and standardization design and the like.

Owner:NAT UNIV OF DEFENSE TECH

Quasi-distributed sea water temperature salinity sensor, measuring device and method thereof

ActiveCN106932026ALow loss characteristicLow insertion lossConverting sensor output opticallyPhysicsSeawater

The invention discloses a quasi-distributed sea water temperature salinity sensor, a measuring device and a method thereof. The sea water temperature salinity sensor is an optical fiber. A number of sensing areas and non-sensing areas are arranged on the optical fiber. Each sensing area comprises a weak grating combination of LPG and FBG. LPG is sensitive to salinity and temperature, and produces power loss with the amplitude related to salinity and temperature for backscattered light. FBG is only sensitive to temperature, and produces power enhancement with the amplitude related to temperature for backscattered light. Single-wavelength pulse laser is input into the optical fiber. A backscattered light signal returned by the optical fiber is detected. The backscattered light signal is demodulated to acquire the sea water temperature and salinity detected by each sensing area. The sea water temperature value and the salinity value of multiple points are measured at the same time. The demodulation step is simple. According to the invention, LPG and FBG are optimized by writing parameters; the loss is low; and cascade long-distance quasi-distributed sea water temperature salinity detection is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

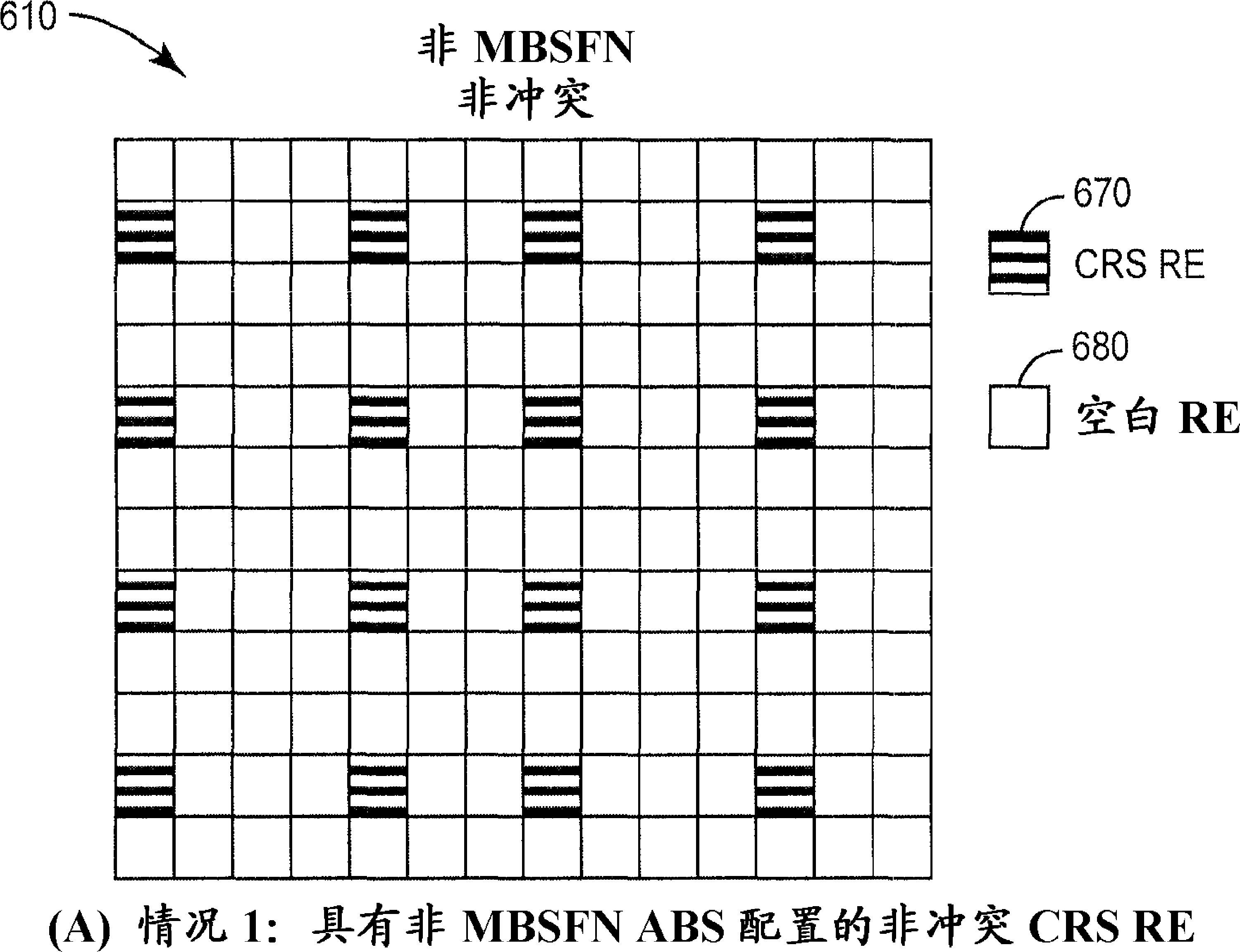

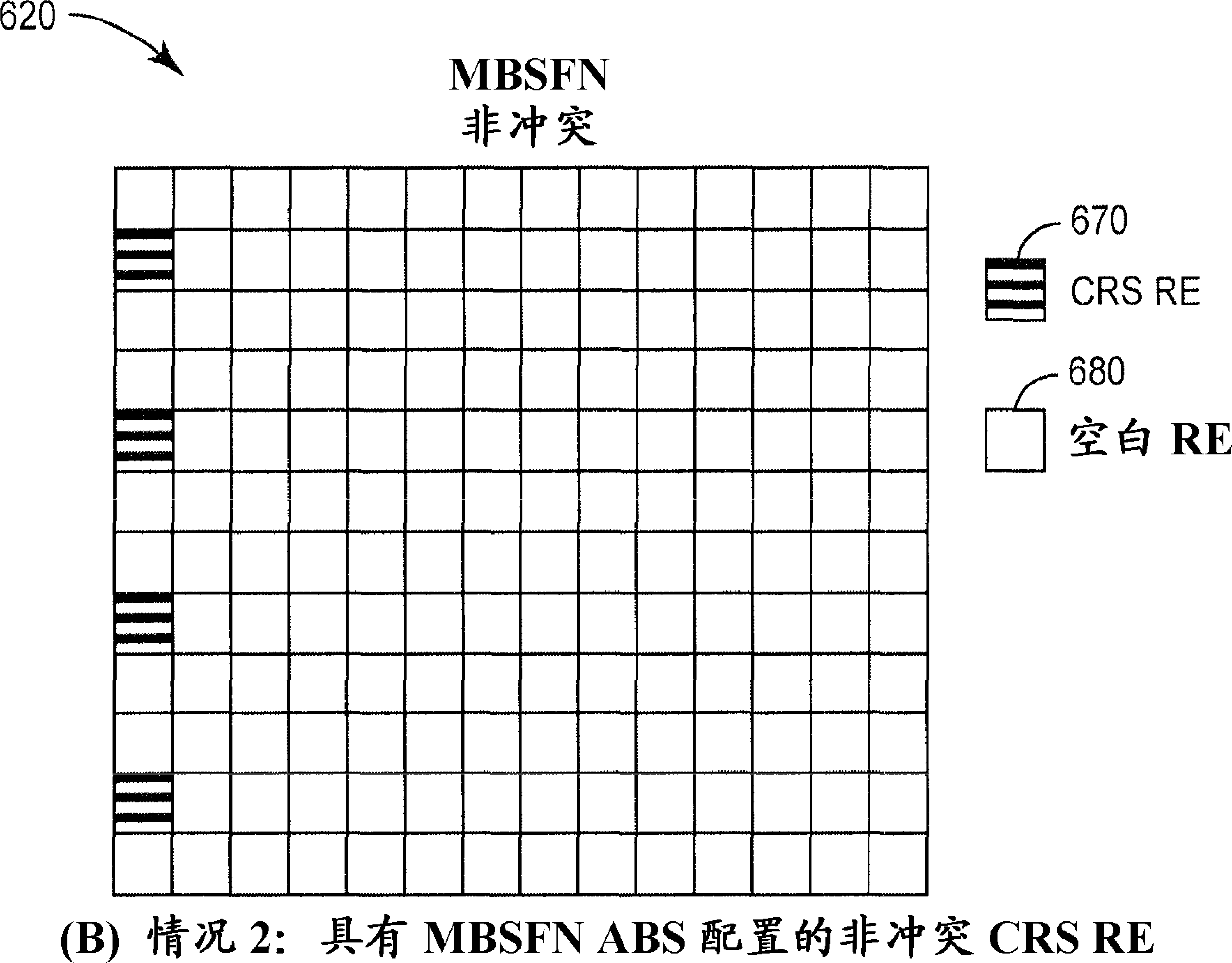

Almost-blank subframe configuration detection in heterogeneous networks

InactiveCN104054383ADescribe wellTransmission is not easy to adaptPower managementSite diversityCell specificResource block

A method for detecting an Almost-Blank Subframe (ABS) configuration for an interfering macro cell of a heterogeneous network is implemented in a wireless terminal. For one or more resource blocks in a received signal, a first power metric is calculated as a function of channel response estimates determined for predicted cell-specific (or common) reference signal (CRS) resource element locations in a plurality of symbols. For the one or more resource blocks in the received signal, a second power metric is calculated as a function of channel response estimates determined for the predicted CRS resource element locations in a single one of the plurality of symbols. A difference between the first and second power metrics is compared to a threshold, and responsive to the comparison a determination is made as to whether the macro cell is operating in a Multicast and Broadcast Single Frequency Network (MBSFN) mode or a non-MBSFN mode.

Owner:TELEFON AB LM ERICSSON (PUBL)

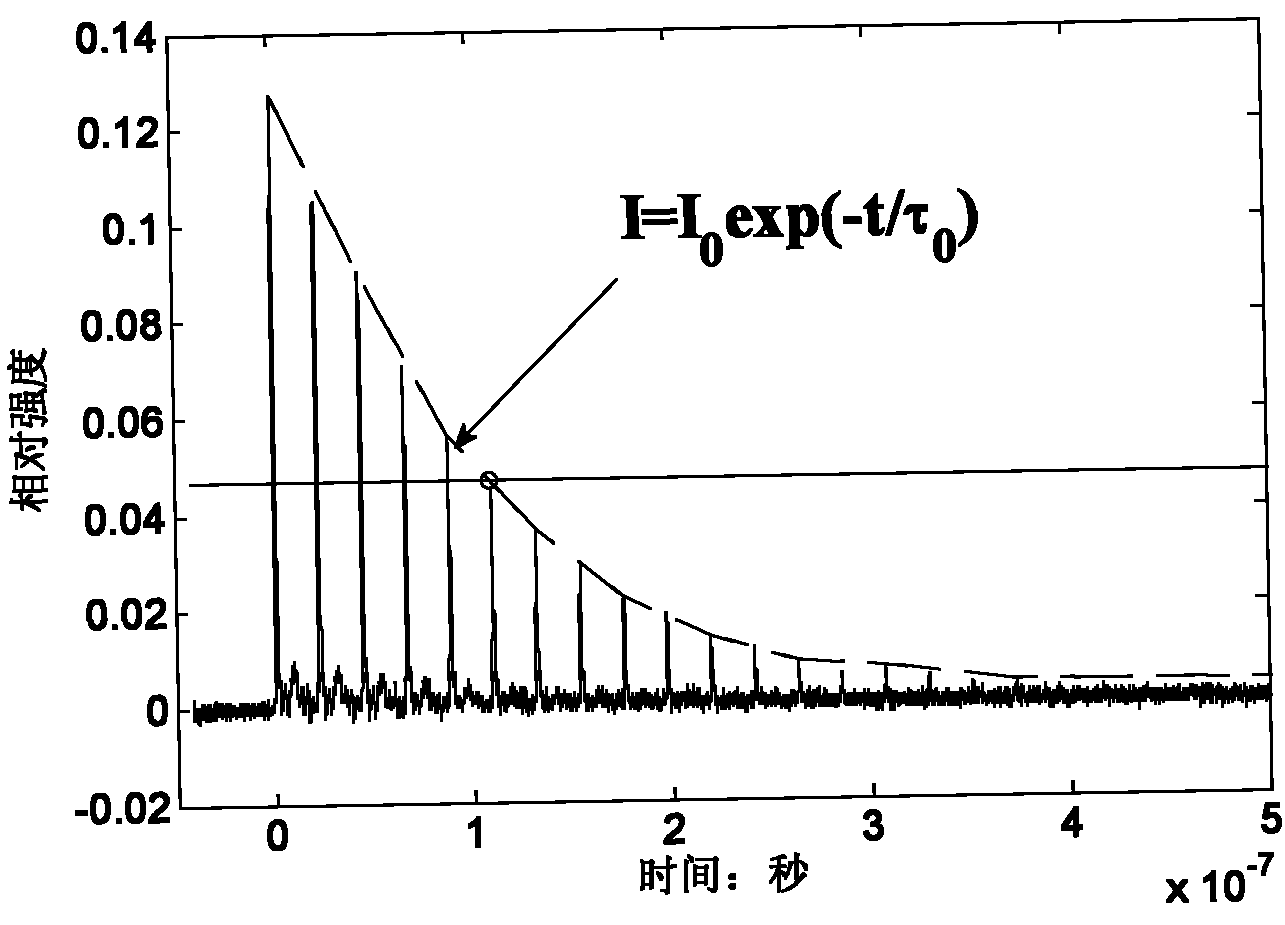

Acoustic wave sensing measurement device based on optical fiber sagnac interferometer

ActiveCN104792402AImprove accuracyIncrease the slopeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansGratingMeasurement device

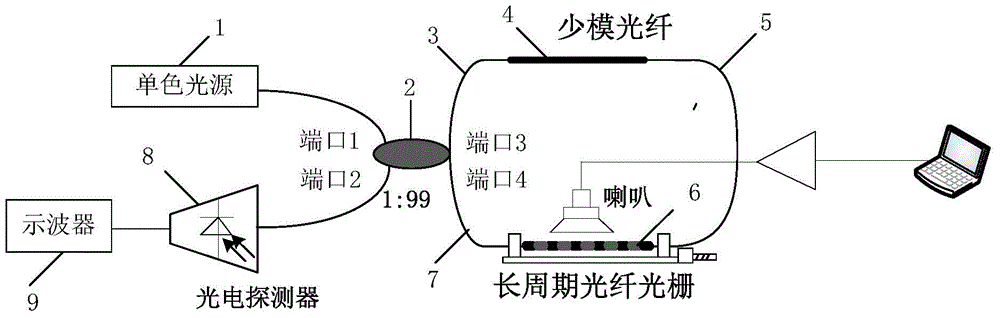

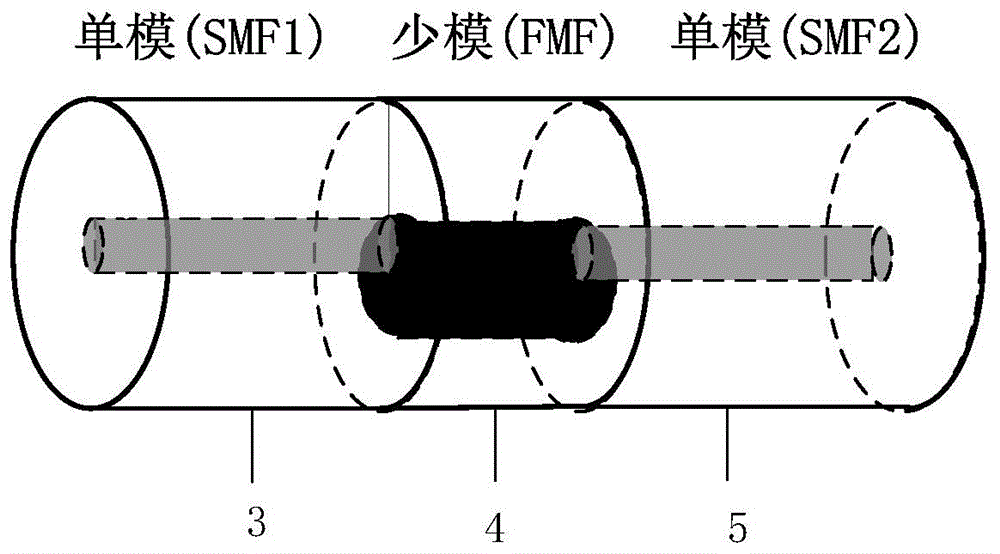

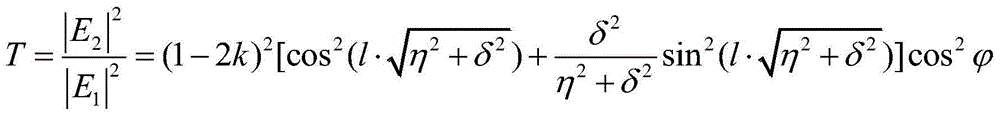

The invention discloses an acoustic wave sensing measurement device based on an optical fiber sagnac interferometer. The acoustic wave sensing measurement device comprises a single-color light source, an optical fiber coupler, a first single-mode optical fiber, a few-mode optical fiber, a second single-mode optical fiber, a long-period optical fiber grating, a third single-mode optical fiber, a photoelectric detector and an oscilloscope, the first single-mode optical fiber, the few-mode optical fiber, the second single-mode optical fiber, the long-period optical fiber grating and the third single-mode optical fiber which are arranged between a third end and a fourth end of the optical fiber coupler are sequentially connected to form a sagnac closed-loop structure, and the long-period optical fiber grating and the few-mode optical fiber realize cascade connection in a sagnac closed-loop. When outside acoustic wave acts on the long-period optical fiber grating, curvature of the outside acoustic wave is modulated by acoustic frequency signals, drift of resonant wavelength at loss peak of the outside acoustic wave is caused, and light power change at a wavelength position corresponding to a bevel edge of the loss peak is analyzed by means of bevel edge demodulation to demodulate to-be-measured acoustic wave signals so as to realize sensing measurement of the acoustic wave signals.

Owner:HUAZHONG UNIV OF SCI & TECH

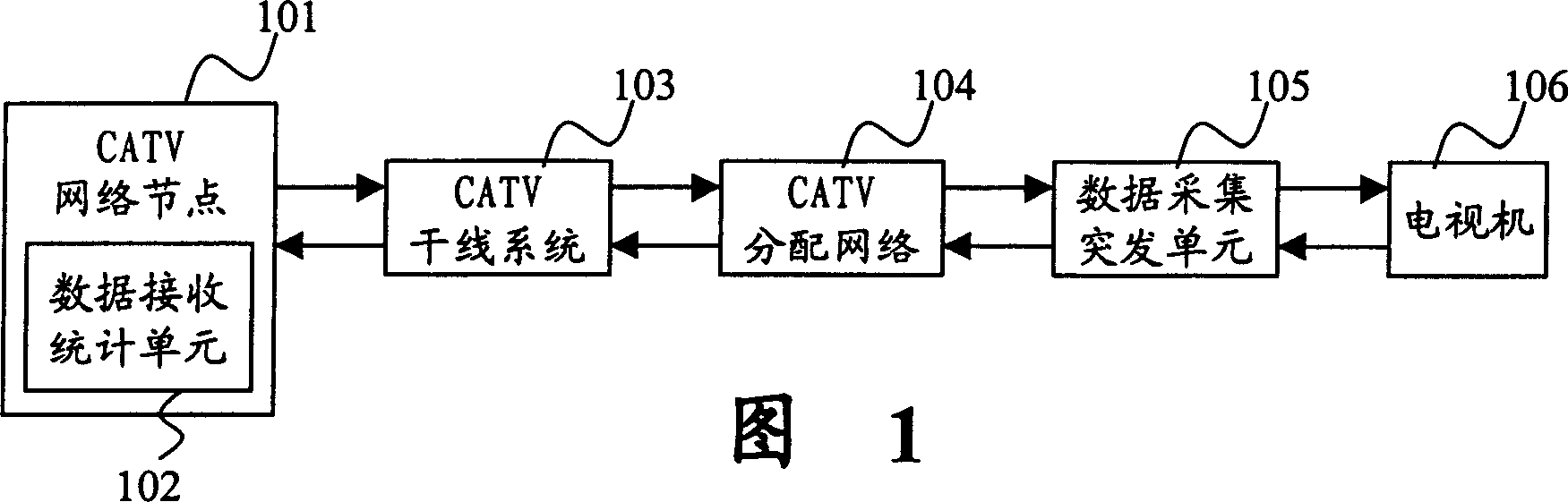

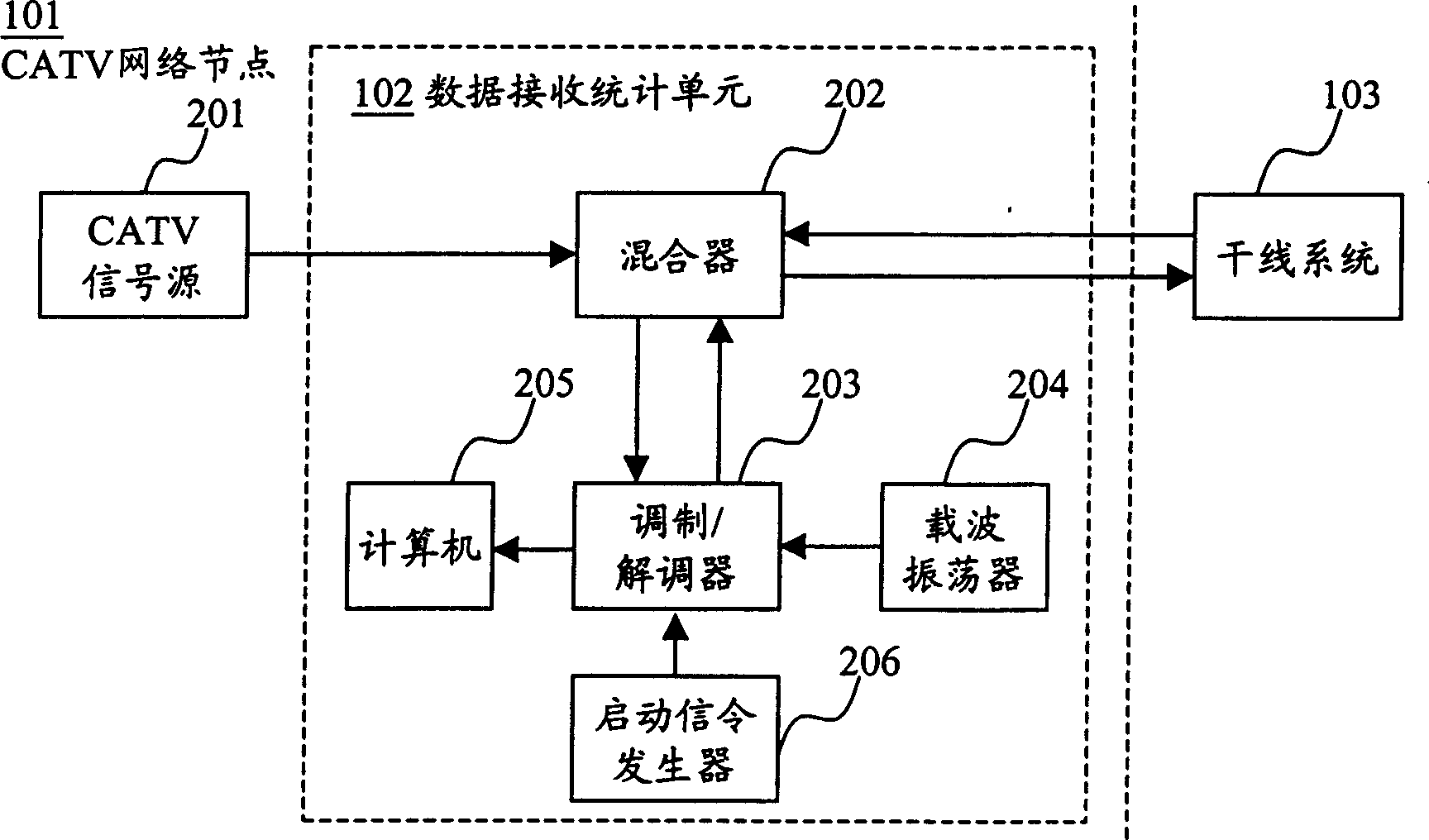

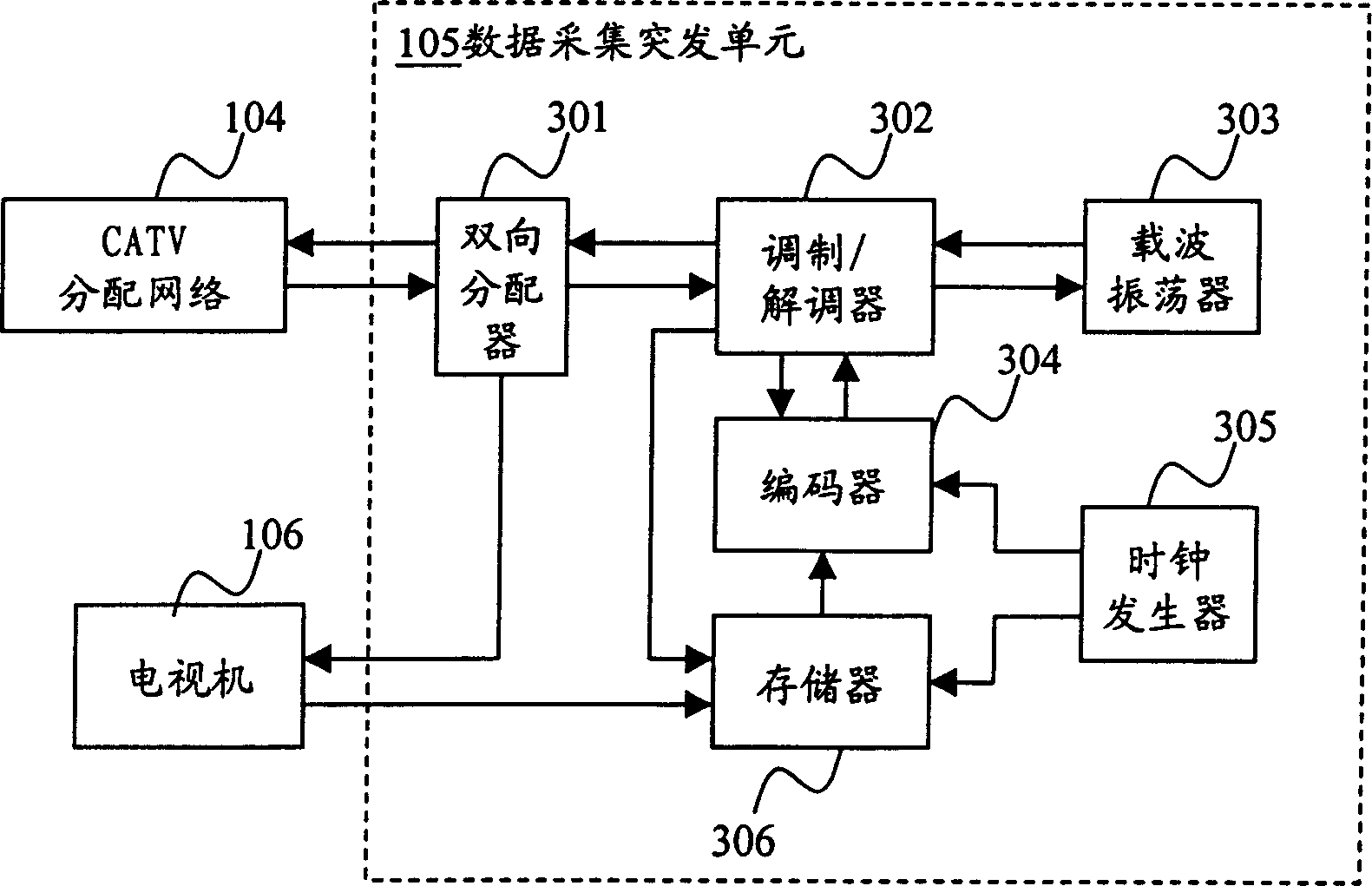

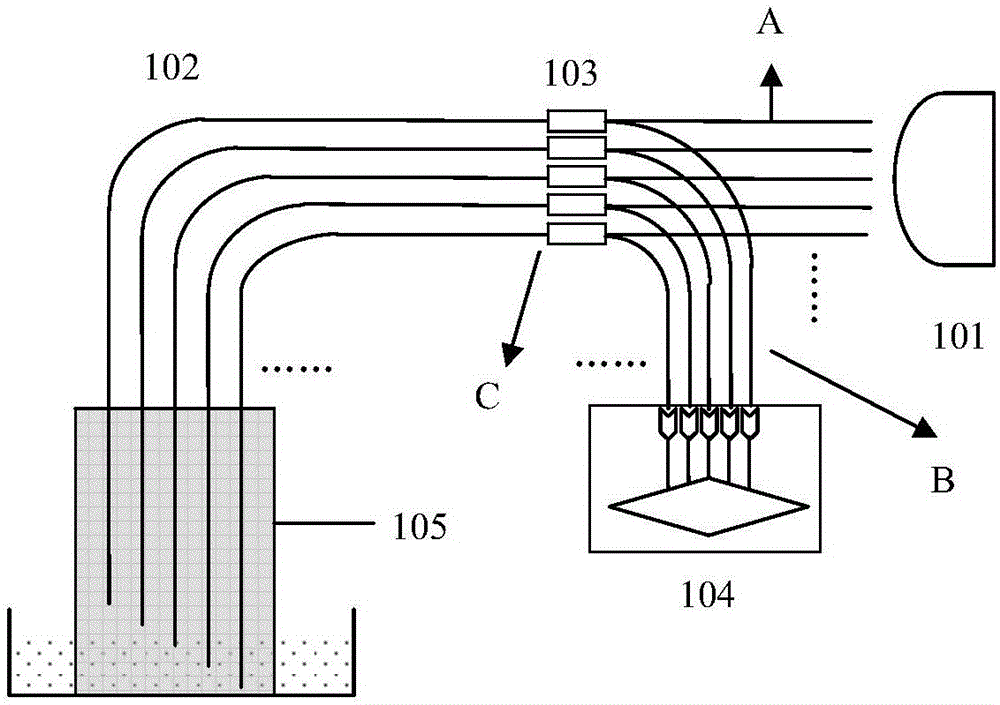

Automatic collection and statistical method and system for TV audience rating

InactiveCN1722821AEfficient managementSimple demodulationTwo-way working systemsElectrical cable transmission adaptationData acquisitionData science

This invention provides a method and system of automatically collecting and counting the television view rate, characterized in that the method comprises the following steps: a) the data receiving and counting unit 102 in CATV network node 101 will send data collecting open signal to the data burst collecting unit 105 in sampling user through the forward direction chain circuit of the two-way CATV network; b) the data collecting burst unit 105 will send the receive data to the receiving and counting unit 102 through the return chain circuit; c) the data receiving and counting unit will dressing, storing, analyzing and counting the returned data; d) getting the estimated value of view rate of the area covered by that network node. If gathering and processing the data of all network nodes, it can count the estimated view rate of bigger range.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

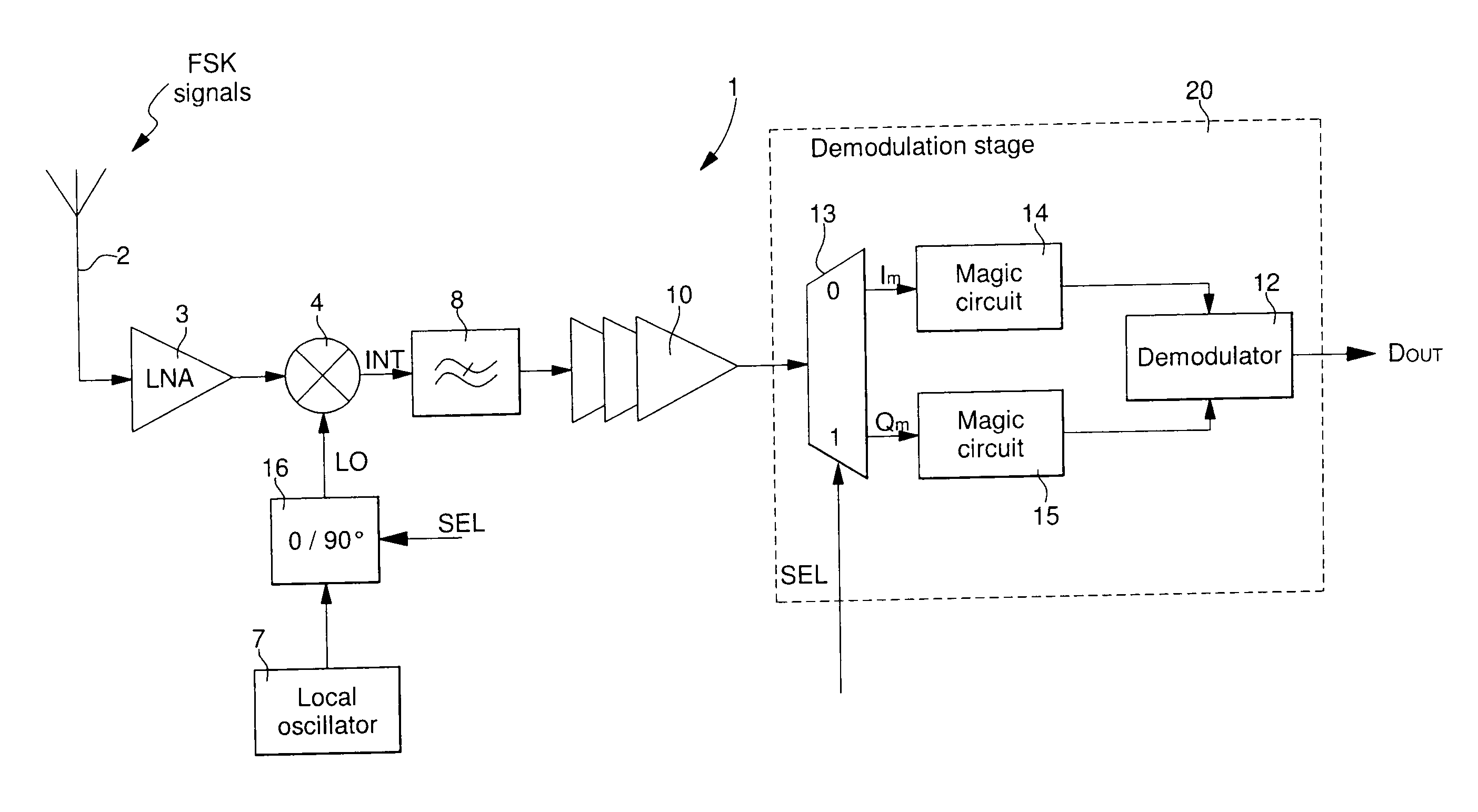

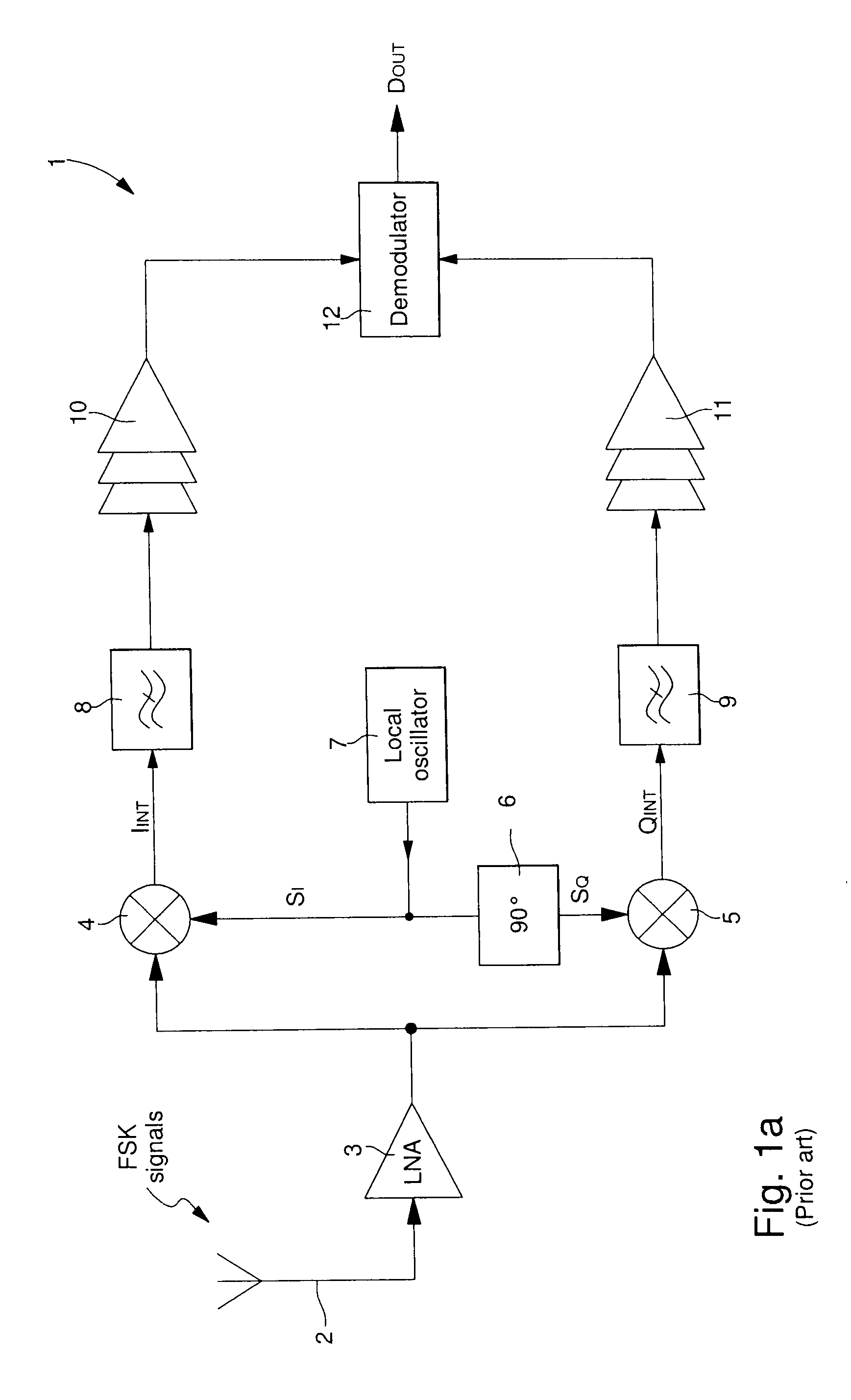

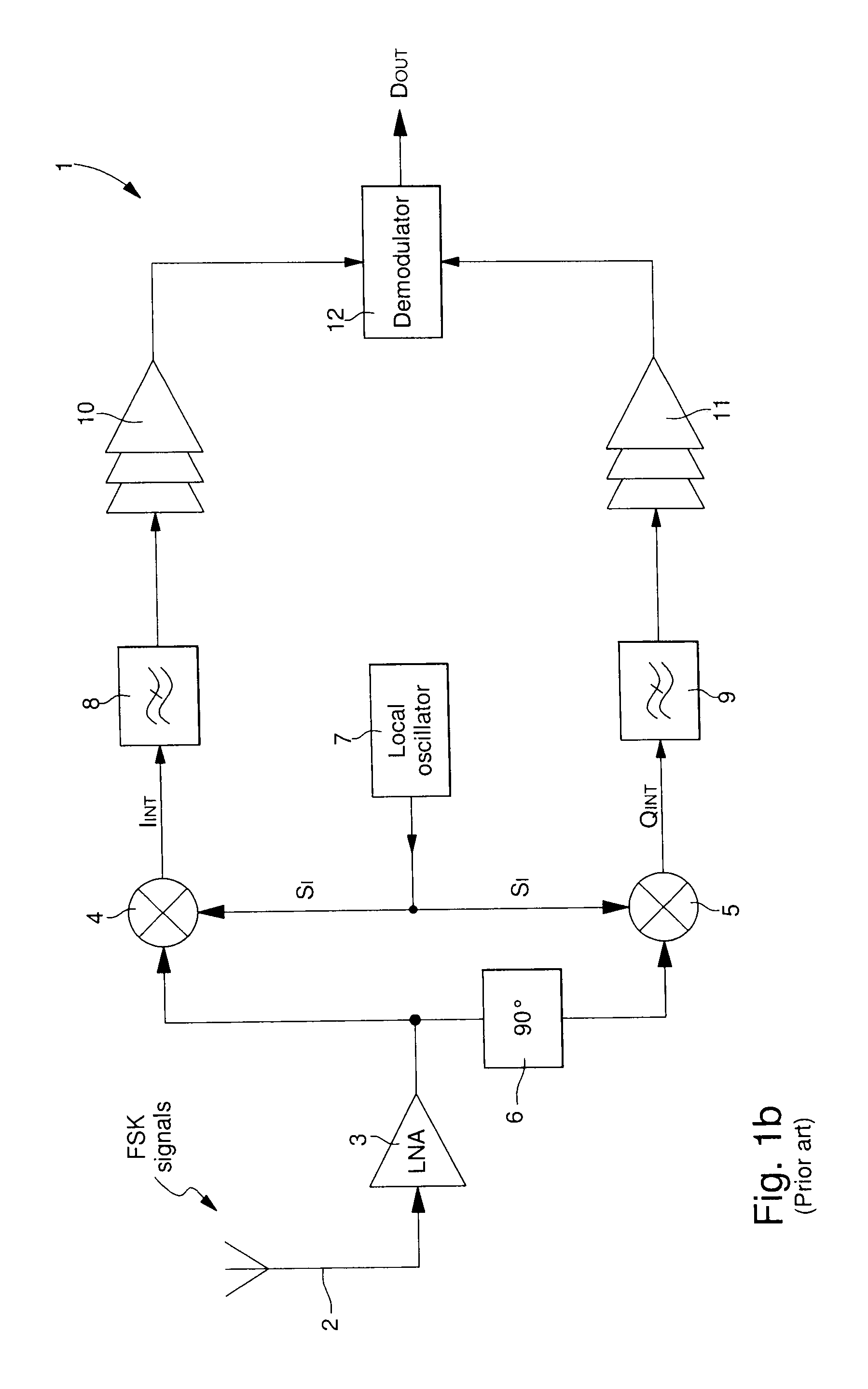

Low rate, direct conversion fsk radio-frequency signal receiver

ActiveUS20120045023A1High sensitivityLow rateFrequency-modulated carrier systemsAngle demodulationLow-pass filterSwitching cycle

The receiver (1) picks up low rate FSK radio frequency signals. This receiver includes an antenna (2) for receiving FSK radio frequency signals, a low noise amplifier (3) connected to the antenna, a local oscillator (7) for supplying oscillating signals (LO), a phase shift circuit (16) for performing a 0° to 90° phase shift, and vice versa, in the oscillating signals (LO) or the incoming FSK radio frequency signals in each semi-period of a phase switching cycle (1 / fs). The phase shift circuit alternately and successively generates in-phase and quadrature oscillating signals, or in-phase and quadrature incoming FSK radio frequency signals. The receiver includes a single mixer (4) for mixing the oscillating signals successively with the incoming FSK radio frequency signals, so as to generate alternately intermediate in-phase and quadrature baseband signals (INT) as a function of the phase shift circuit. The receiver further includes a low-pass filter (8) for filtering the intermediate in-phase and quadrature signals, and a demodulation stage (20) for demodulating the data (DOUT) from the filtered intermediate signals. The receiver is arranged such that the phase shift circuit (16) is switched by a phase selection signal (SEL) to a phase switching cycle frequency (fs) which is lower than the frequency deviation (Δf) of the modulated data in the FSK radio frequency signals and higher than the data rate frequency. Magic circuits (14, 15) in the demodulation stage reconstruct the intermediate signals during each switch operation for continuous demodulation in the demodulator (12).

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

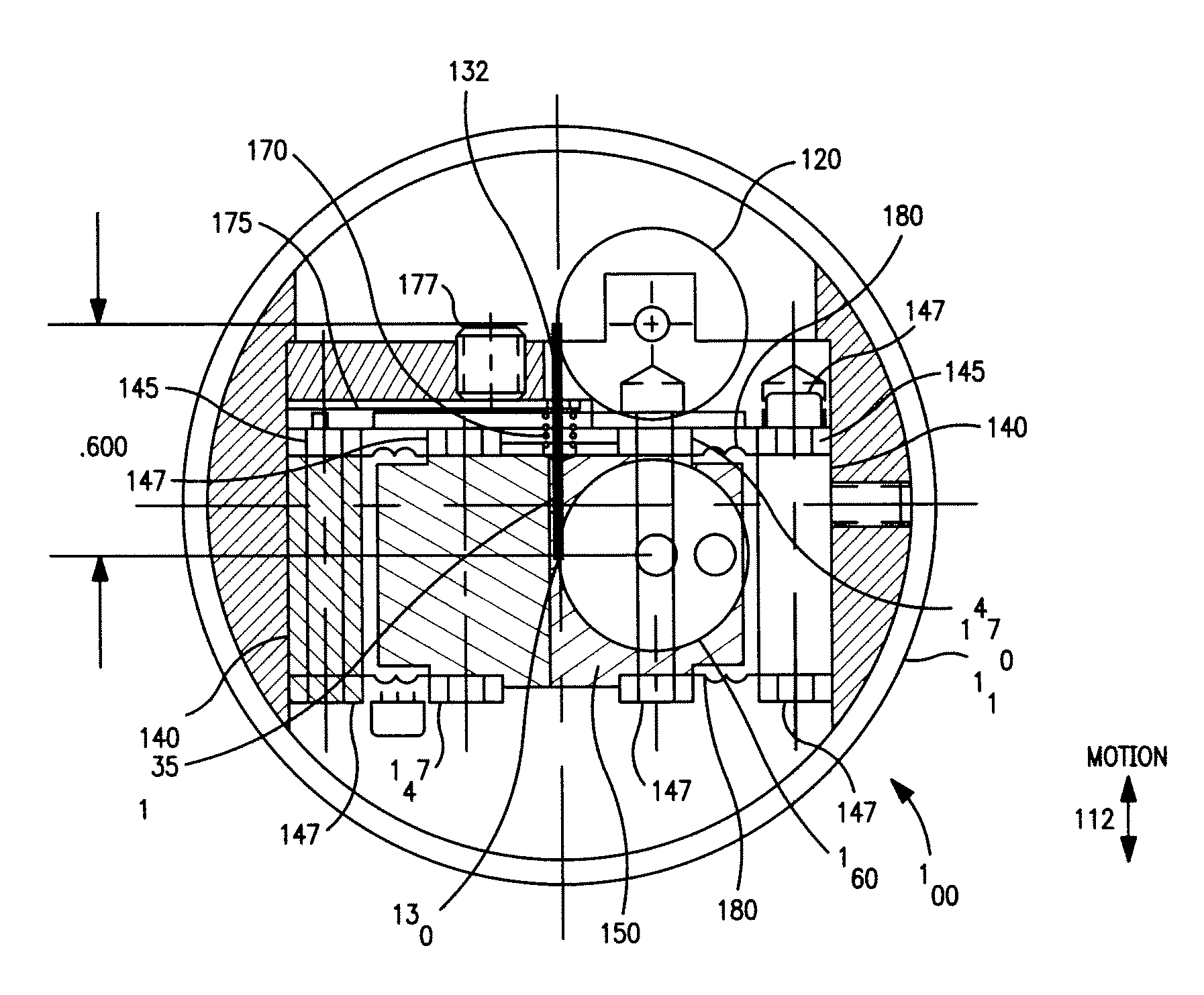

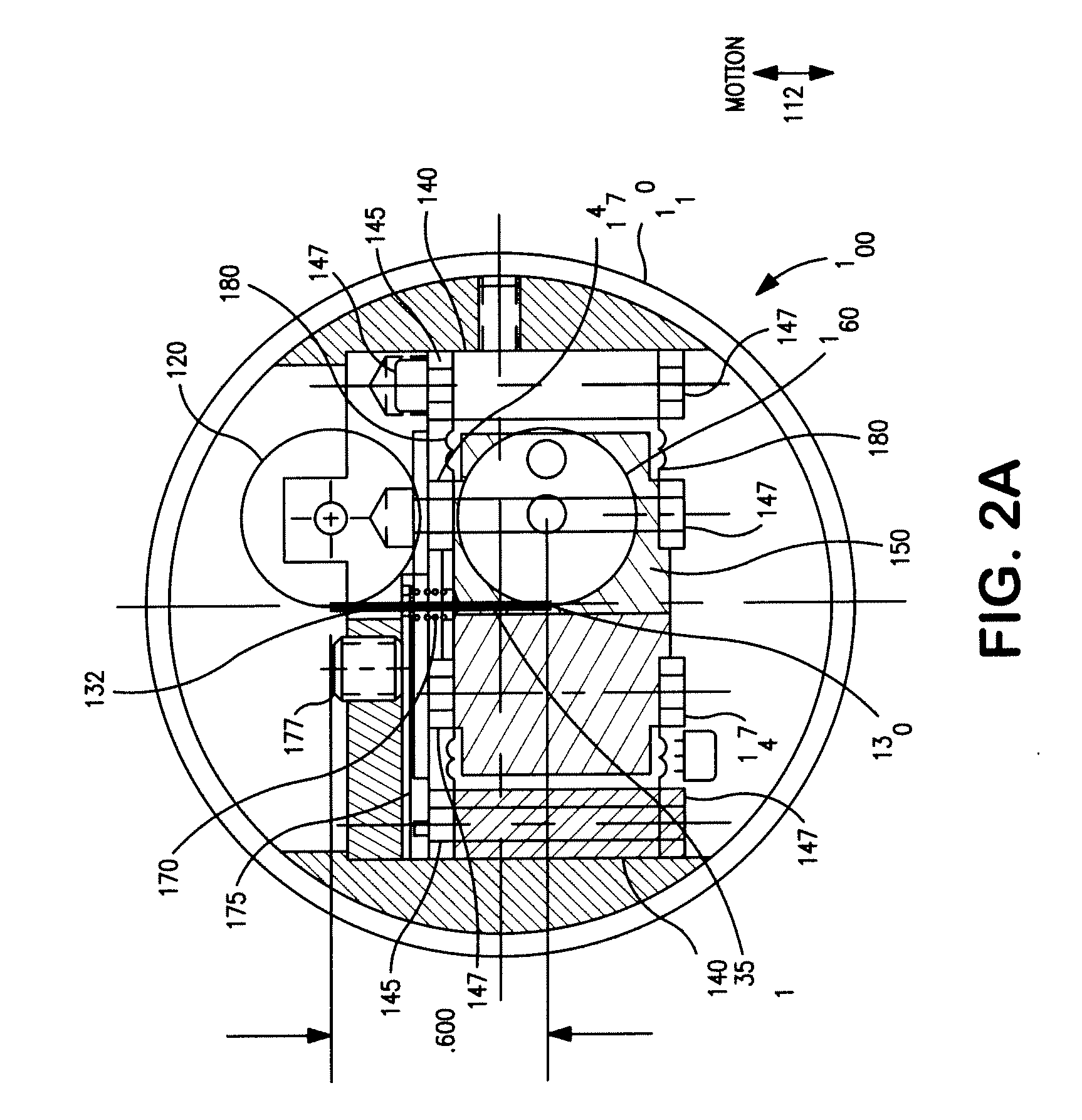

Fiber optic particle motion sensor system

ActiveUS20100313658A1Simple demodulationHigh level of performanceAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementPhysicsFiber interferometer

A sensor apparatus combines an optical sensor in which acceleration, acoustic velocity, or displacement (vibration) causes a corresponding shift in the center wavelength of the sensor output, coupled to a high speed interferometric interrogator, through an unbalanced fiber interferometer. The unbalanced interferometer functions to translate optical wavelength shift into phase shift, which is easily demodulated by the interrogator.

Owner:AVALON SCI

Micro-machine magnetic field senor and application thereof

ActiveCN105988090AHigh sensitivityIncrease the amount of changeElectrodynamic magnetometersPiezoelectric/electrostrictive devicesInsulation layerResonance

The present invention provides a micro-machine magnetic field senor and an application thereof. The sensor at least comprises a resonance oscillator and an insulation layer and at least one layer of metal coil arranged on the surface of the resonance oscillator in order. An S-shaped folding beam is employed to realize the connection of an elastic beam and an anchor to ensure that the resonance oscillator is moved along the direction perpendicular to the resonance oscillator when the resonance oscillator is subjected to resonance and greatly improve the variation of a resonance beam in the enclosed area unit time compared to a square ring formed by a general dual-end fixed support beam so as to increase the variation of the magnetic flux in the metal coil and the sensitivity of a magnetic field. Besides, a grounding aluminium layer is added in the insulation layer of the metal coil to effectively avoid the problem that the signals of the resonance oscillator are coupled to the metal coil. The micro-machine magnetic field senor and the application thereof are simple in structure and reduce the loss of a device with no need for current communication on the metal coil; and moreover, the size of the magnetic field is measured through measurement of the induced electromotive force at two ends of the metal coil, and therefore the influence of the temperature is small.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Pilot signal enhancements for a wireless communication system

ActiveUS20080205374A1Improve the usefulnessImprove effectivenessEnergy efficient ICTPower managementTraffic signalTelecommunications

Owner:APPLE INC

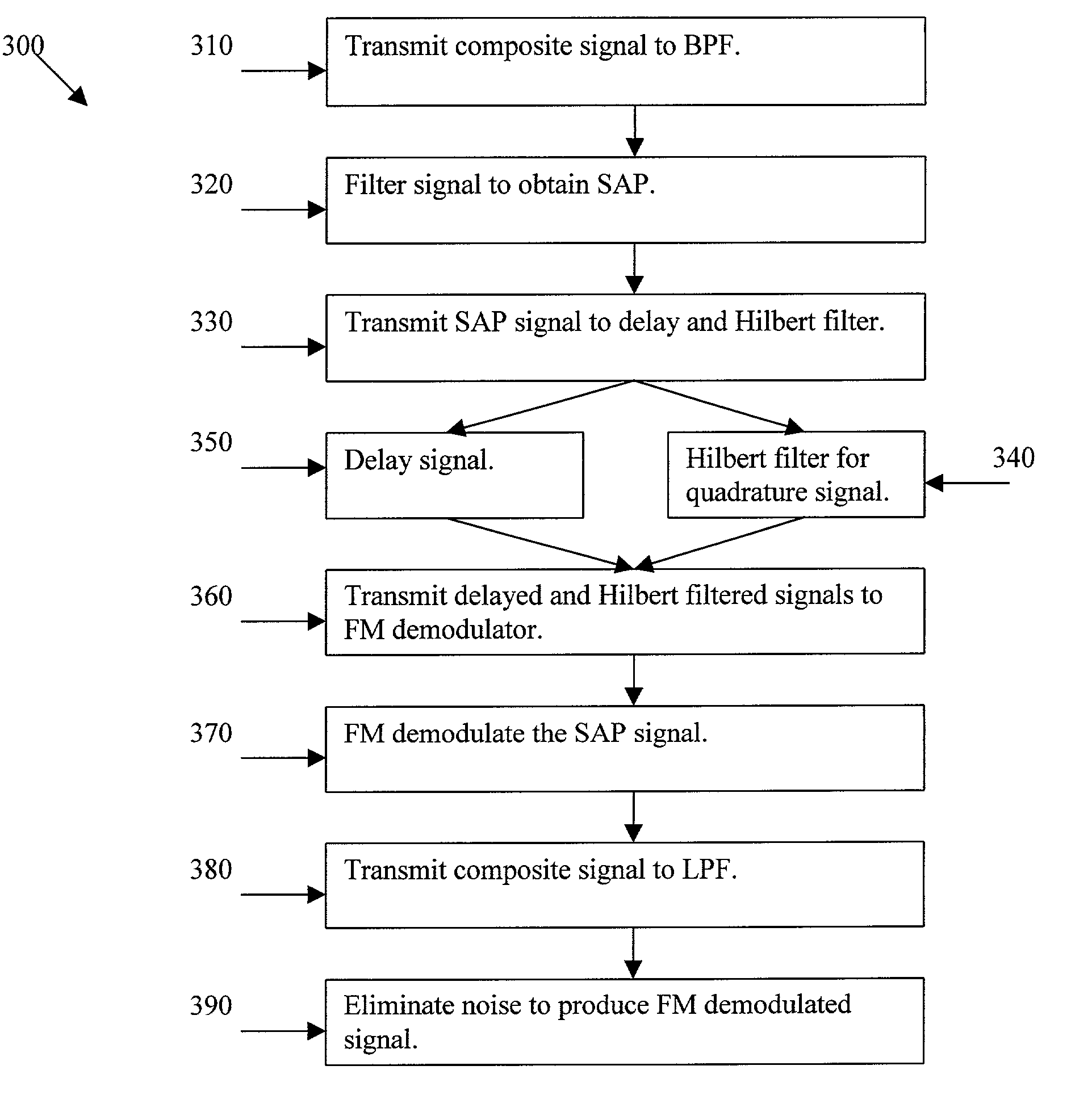

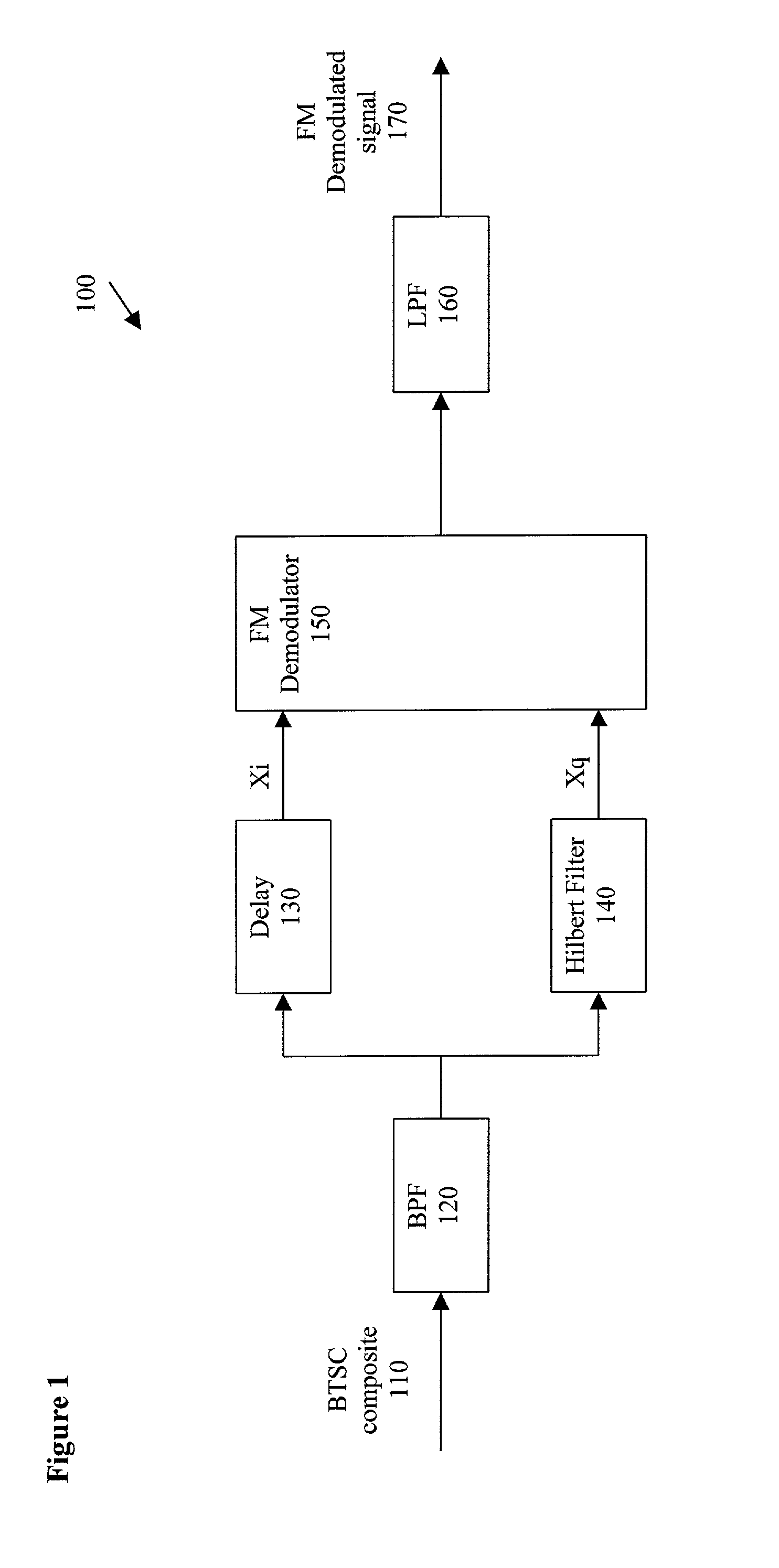

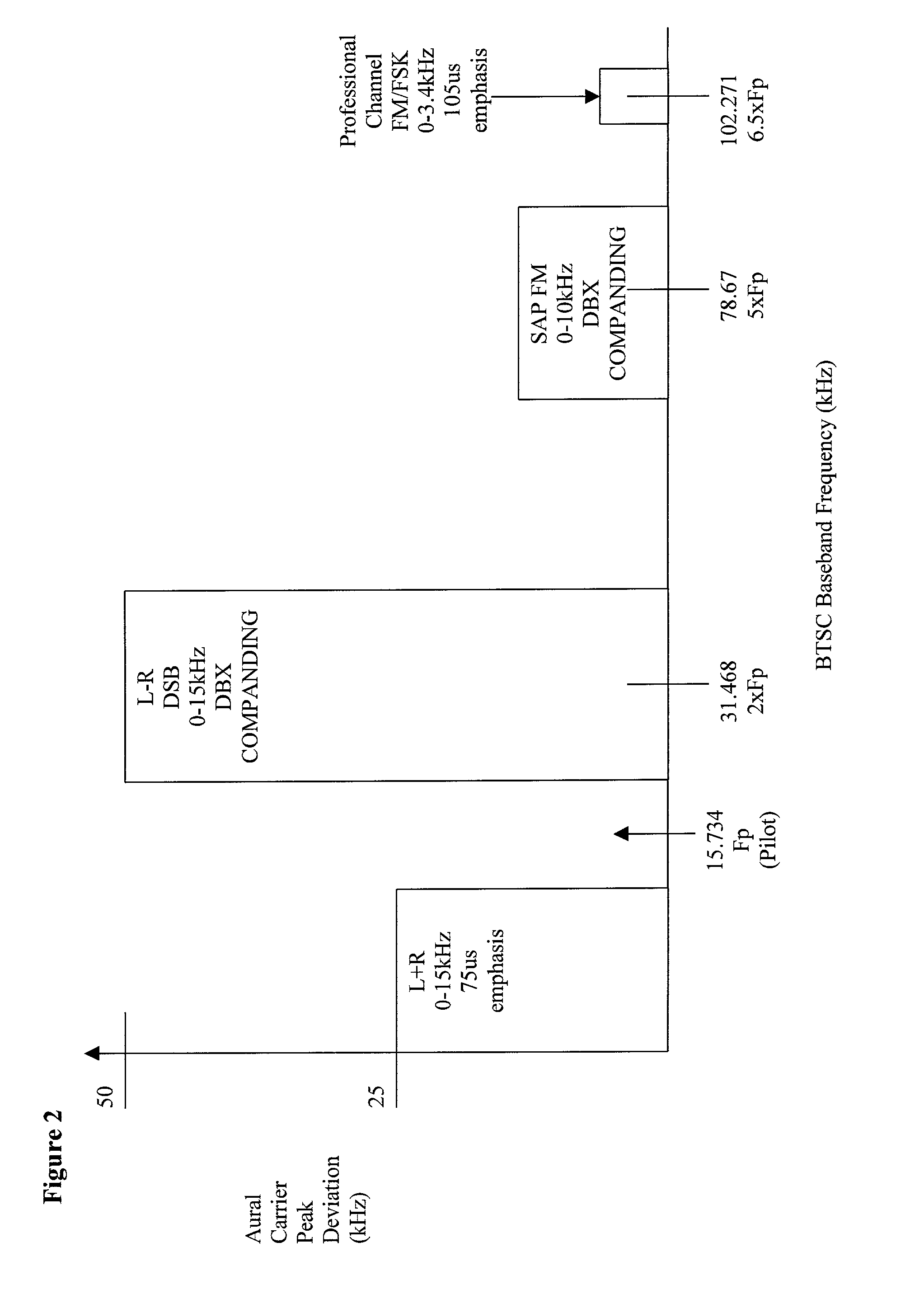

System and method for SAP FM demodulation

InactiveUS7006806B2Simple signalCancel noiseTelevision system detailsColor television detailsBandpass filteringPhase shifted

Certain embodiments of the present invention provides a system and method for SAP FM demodulation. The system includes a bandpass filter for isolating the SAP signal, a Hilbert filter to produce a copy of the SAP signal phase shifted by 90 degrees, an FM demodulator for demodulating the SAP signal using the phase shifted SAP signal and a delayed SAP signal, and a lowpass filter to eliminate noise from the FM demodulated SAP signal. The system may also include an automatic gain control for normalizing amplitude of FM demodulator input signals. The digital FM demodulator uses a simplified approximation using non-unity delay for simplified demodulation of frequency modulated signals.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

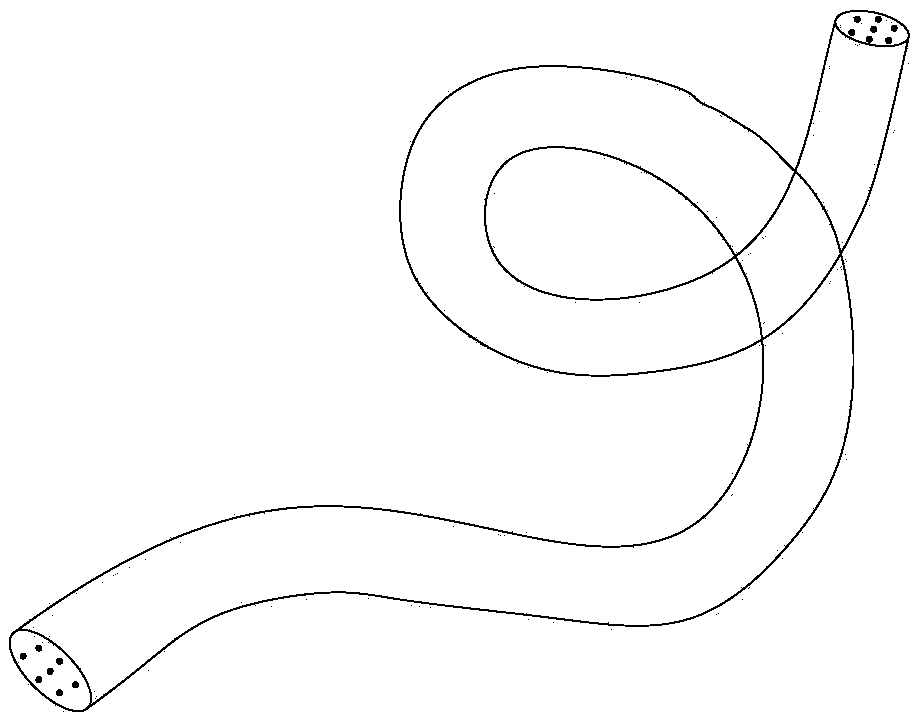

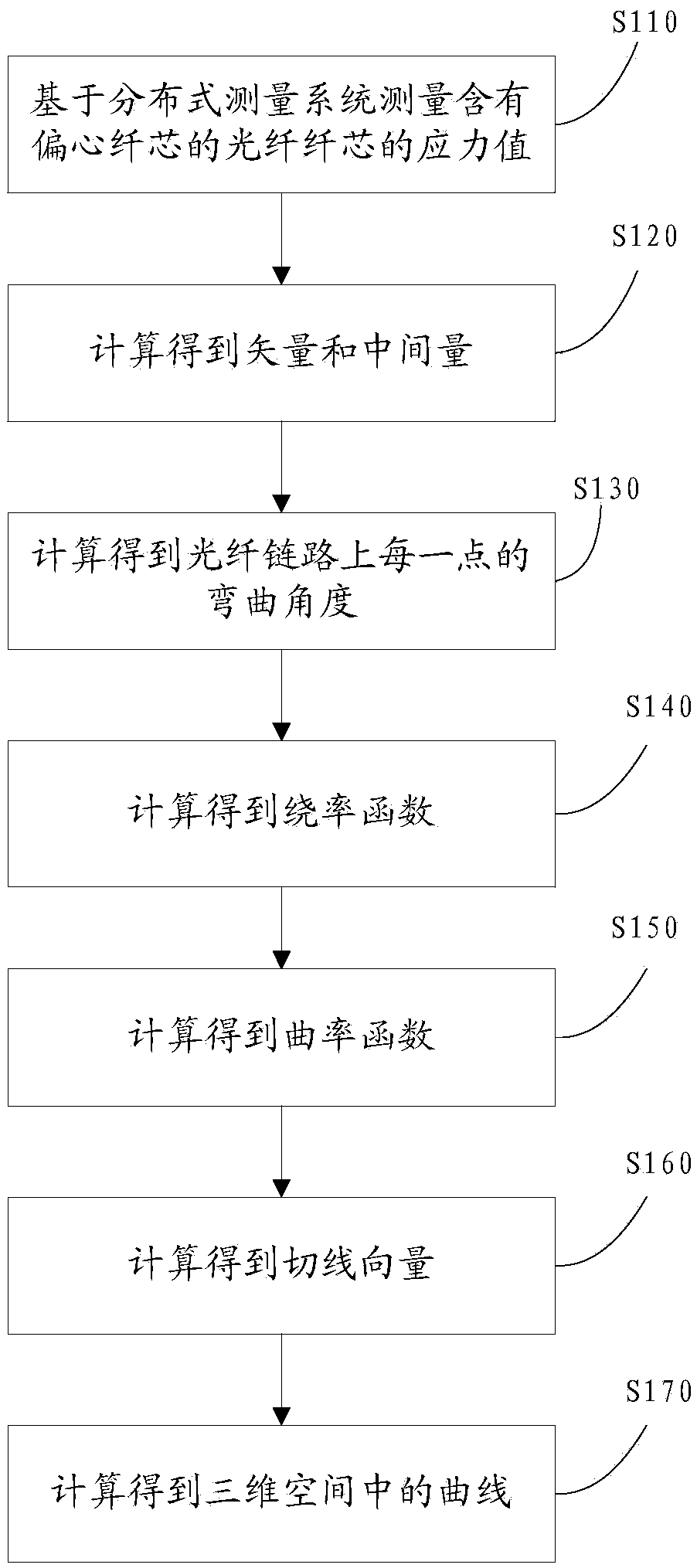

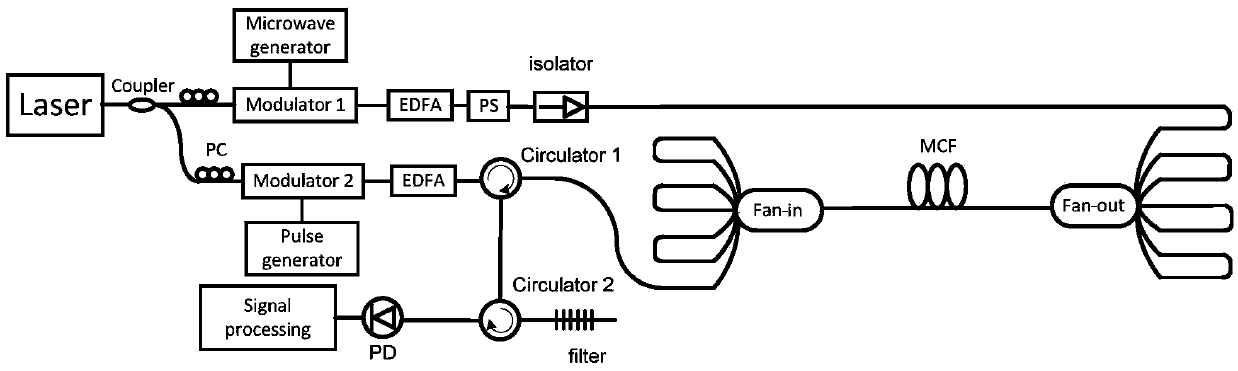

Three-dimensional shape measurement method

The invention discloses a three-dimensional shape measurement method. The method comprises steps: based on a distributed measurement system, a stress value of an optical fiber core with an eccentric fiber core is measured; a vector and an intermediate variable are acquired; a bent angle of each point in an optical fiber link is acquired; a torsion function is acquired; a curvature function is acquired; a tangent vector is acquired; and a curve in three-dimensional space is acquired. The fact that a fiber Bragg grating is inscribed in a multi-core optical fiber in the prior art is not needed, the distributed sensor based on the method of the invention is convenient to make and convenient to demodulate, the making process and the steps for the sensor are simplified, and the implementing cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

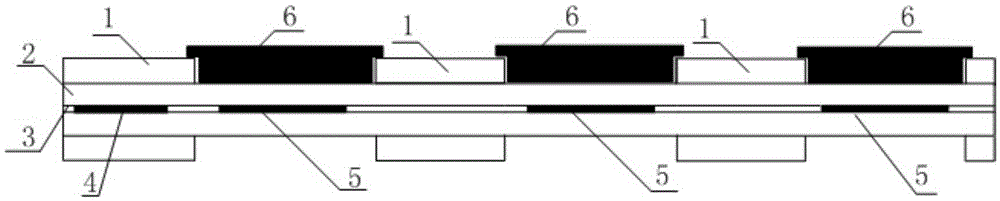

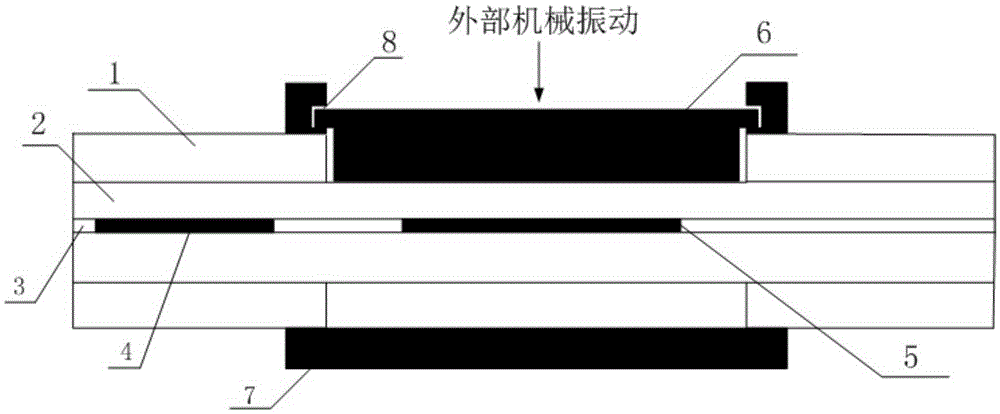

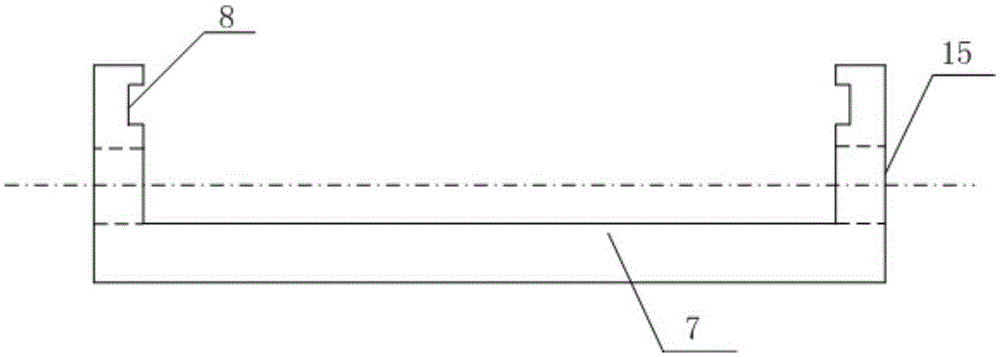

Great-angle tilted fiber bragg grating mechanical vibration sensing array and system

ActiveCN105387923ASmall sizeNo currentSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberGrating

The invention discloses a great-angle tilted fiber bragg grating mechanical vibration sensing array and a great-angle tilted fiber bragg grating mechanical vibration sensing system. The great-angle tilted fiber bragg grating mechanical vibration sensing array comprises an optical fiber core, and is characterized in that: the front section of the optical fiber core is provided with a 45-degree tilted fiber bragg grating, and the 45-degree tilted fiber bragg grating serves as a polarizer of a great-angle tilted fiber bragg grating vibration sensor; an included angle between tilted grating stripes of the tilted fiber bragg grating and an optical fiber cross section is 45 degrees; the middle section of the optical fiber core is provided with N great-angle tilted fiber bragg gratings, and N is a natural number greater than or equal to 1; grating stripes of the N great-angle tilted fiber bragg gratings are parallel to one another, and an included angle between the tilted grating stripes of each great-angle tilted fiber bragg grating and the optical fiber cross section ranges from 79 to 84 degrees; and the outer surface of an optical fiber cladding corresponding to each great-angle tilted fiber bragg grating is provided with an elastic membrane. The great-angle tilted fiber bragg grating mechanical vibration sensing array and the great-angle tilted fiber bragg grating mechanical vibration sensing system can be widely used in the fields of optical fiber perimeter and structural safety monitoring, landslide early warning and the like.

Owner:CHONGQING UNIV OF TECH

Long distance passive liquid level sensor based on distributed fibers

ActiveCN106595807AHigh measurement accuracyReduced measurement accuracyNuclear energy generationMachines/enginesFiberLuminous intensity

The invention discloses a long distance passive liquid level sensor based on distributed fibers, for solving the problem that a current fiber liquid level sensor has low accuracy and low stability. The long distance passive liquid level sensor based on distributed fibers comprises a light source, a comparison circuit, a wavelength division multiplexing device array formed by N wavelength division multiplexing devices, and a fiber array formed by N fibers, wherein pumping arms of the N wavelength division multiplexing devices are connected with the light source; signal arms of the N wavelength division multiplexing devices access the comparison circuit; beam combination arms of the N wavelength division multiplexing devices are correspondingly connected with head ends of the N fibers one to one; tail ends of the N fibers are measuring ends; the vertical distance between the end surfaces of the tail ends of the two adjacent fibers is x, and x is the measuring accuracy to be achieved. The long distance passive liquid level sensor based on distributed fibers can determine the liquid level position according to the abrupt change position of luminous intensity, being similar to digital detection, wherein the measuring accuracy is mainly decided by the distributed spacing of the fibers. Besides, the long distance passive liquid level sensor based on distributed fibers can eliminate the influence of energy shaking of light source and external disturbance on measurement, is slightly influenced by environment, and has high measuring accuracy and high stability.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com