Device and method for automatic, static continuous preparation of fiber bragg grating array

A technology of fiber grating array and fiber grating, which is applied in cladding optical fiber, optical waveguide light guide, etc., can solve the problems of low production cost and high mechanical strength of fiber grating array, and achieve high mechanical strength, simple operation and easy realization, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

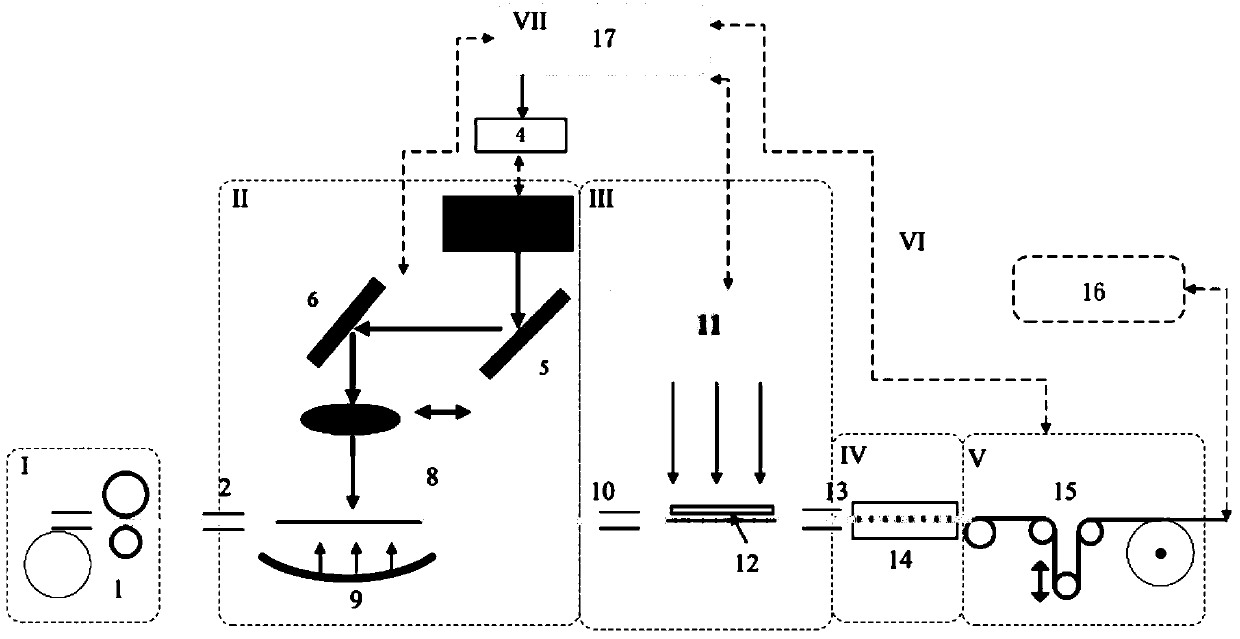

[0037] like figure 1 As shown, a device of the present invention for automatically and continuously preparing a fiber grating array comprises an optical fiber pay-off module I, a coating layer stripping module II, a grating writing module III, a coating module IV and Fiber collection module V, in addition, in order to facilitate the process monitoring of some modules and the automatic control of the whole device, there is also a fiber grating array online monitoring module VI and a computer control module VII. In the optical fiber pay-off module I, the coating layer stripping module II and the grating writing module III, there are optical fiber clamps between the two adjacent modules for the support and temporary fixation of the optical fiber, so as to realize the operation performed by each module. In the embodiment, the optical fiber el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com