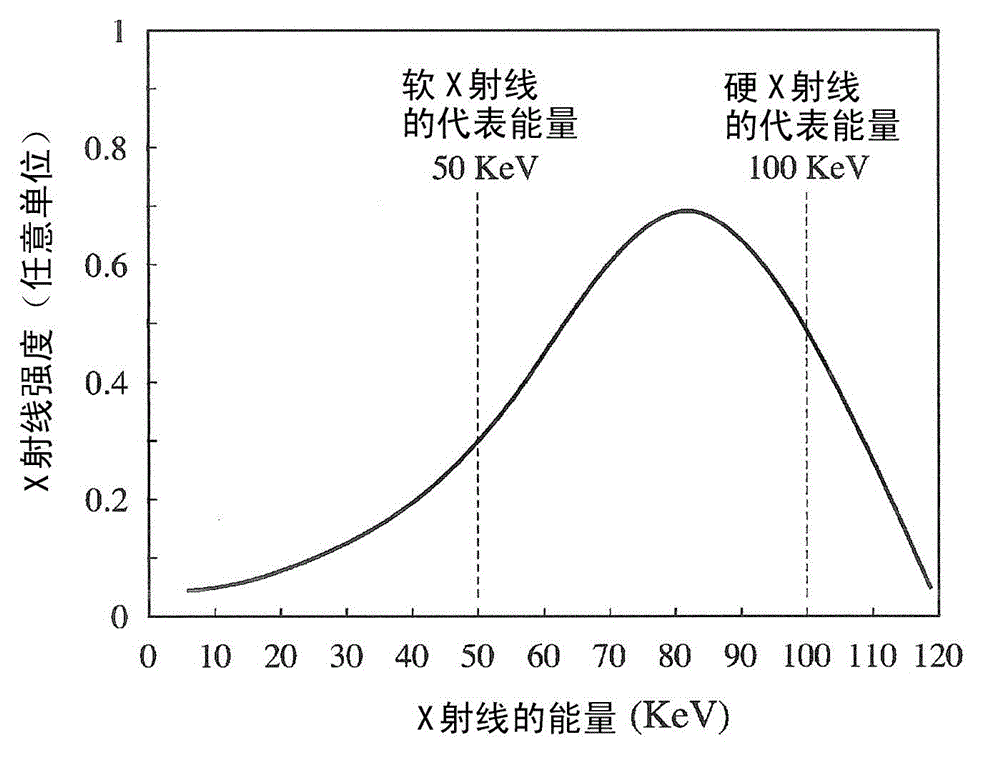

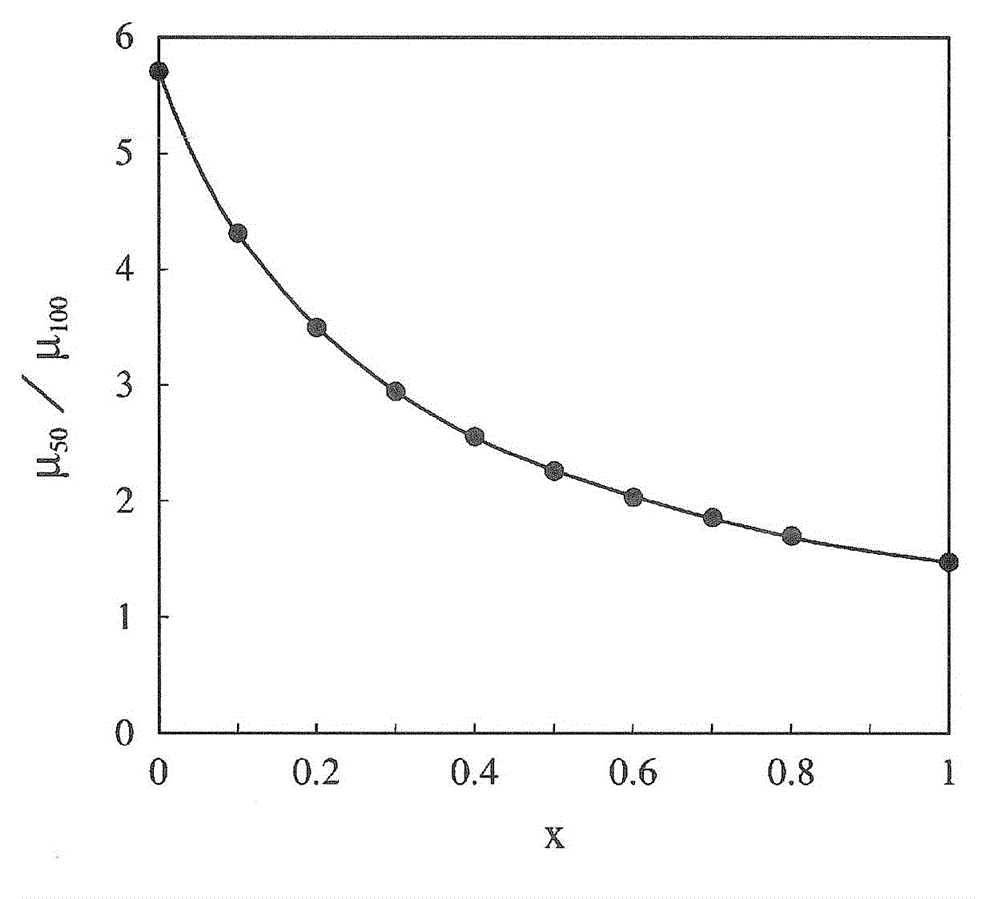

Polycrystalline scintillator for detecting soft x-rays

An X-ray and scintillator technology, which is applied in the field of polycrystalline scintillator for soft X-ray detection, can solve the problems of toxicity, price, characteristic deviation, and insufficient X-ray luminous intensity, and achieve large absorption coefficient, less afterglow, The effect of small absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] In a resin kettle with a capacity of 1 liter, together with 1300 g of high-purity alumina balls with a diameter of 5 mm and 200 cc of ethanol, the Al from the alumina balls was considered. 2 O 3 In the case of mixing, put 73.79g of Y 2 O 3 Powder, 29.80g Gd 2 O 3 Powder, 0.77g CeO 2 Powder, 38.16g of Al 2 O 3 Powder and 57.48g of Ga 2 O 3 A total of 200 g of raw material powder composed of powder. In order to reduce the content of Fe and Si, the Al 2 O 3 The powder was preliminarily heat-treated in a vacuum (10 Pa or less) at 1400° C. for 1 hour, and then pulverized by a ball mill for 12 hours. After mixing the raw material powder in a wet ball mill for 12 hours, drying was performed. The mass change of the alumina balls mixed by the wet ball mill was 0.06 g. The average particle diameter of the wet ball mill mixed powder determined by using a laser diffraction particle size distribution analyzer (LA920 manufactured by Horiba, Ltd.) and having an average re...

Embodiment 2

[0075] Use Y from 73.61g 2 O 3 Powder, 29.73g of Gd 2 O 3 Powder, 0.706g CeO 2 Powder, 38.26g of Al 2 O 3 Powder and 57.64g of Ga 2 O 3 A polycrystalline scintillator of Example 2 having the composition shown in Table 2 was produced in the same manner as in Example 1, except that the raw material powder was composed of powder.

Embodiment 3

[0077] Use Y from 75.47g 2 O 3 Powder, 30.48g Gd 2 O 3 Powder, 0.724g CeO 2 Powder, 37.21g of Al 2 O 3 Powder and 56.05g of Ga 2 O 3 A polycrystalline scintillator of Example 3 having the composition shown in Table 2 was produced in the same manner as in Example 1 except that the raw material powder was composed of powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com