Method for growing low-absorption phosphorus germanium zinc crystal

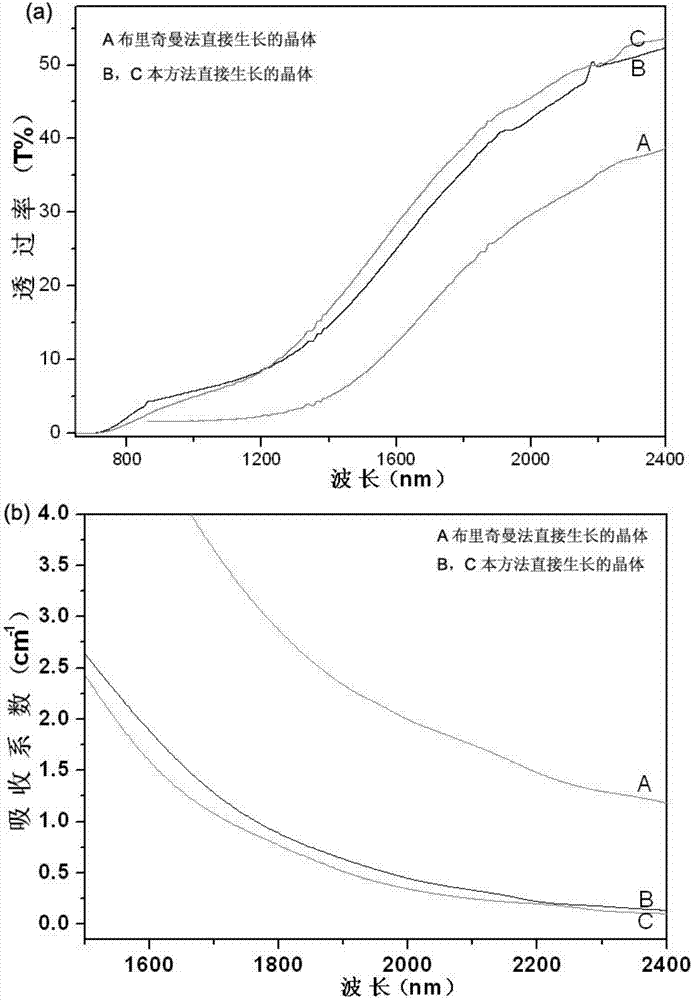

A technology of crystal growth and crystal growth furnace, which is applied in the growth of phosphorus-germanium-zinc crystals and the field of phosphorus-germanium-zinc crystals. It can solve problems such as troublesome, low-absorption crystal yields, etc., and reduce dislocations and intrinsic point defects. , The effect of improving crystal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Cooling Growth of Phosphorus, Germanium and Zinc Crystals with Low Absorption

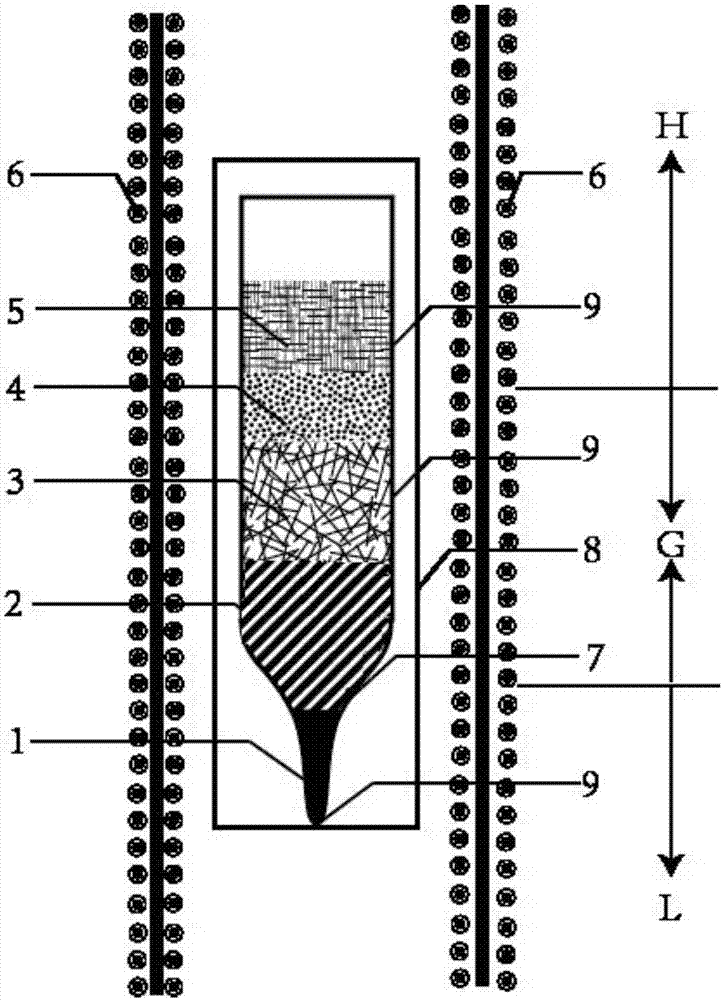

[0030] ① Design and manufacture a crystal growth furnace with three temperature zones with suitable gradients, which are divided into low temperature zone, gradient zone and high temperature zone, and the temperature gradient in the gradient zone is 5°C / cm;

[0031] ② Coating the surface of the corundum crucible with a carbon film layer;

[0032] ③Put the oriented phosphorus-germanium-zinc seed crystal into the crucible seed crystal groove, ZnF 2 And Ge 40g, pre-grown phosphorus germanium zinc high-purity polycrystalline raw material 100g, 20mm thick about 12g anhydrous B 2 o 3 Put them in order, and finally place the crucible in the quartz tube as a whole, and vacuumize to 10 at room temperature. -2 Pa and sealed;

[0033] ④ Put the sealed quartz tube into the crystal growth furnace, and place the end with the seed crystal, flux and polycrystalline material between the gradient zone and...

Embodiment 2

[0038] Descend Growth of Low Absorption Phosphorus, Germanium and Zinc Crystals

[0039] ① Design and manufacture a crystal growth furnace with three temperature zones with suitable gradients, which are divided into low temperature zone, gradient zone and high temperature zone, and the temperature gradient in the gradient zone is 6°C / cm;

[0040] ②Clean and dry the growing graphite crucible with deionized water, and coat the surface of the crucible with a carbon film;

[0041] ③Put the oriented phosphorus-germanium-zinc seed crystal into the crucible seed crystal groove, ZnF 2 And Ge 40g, pre-grown phosphorus germanium zinc high-purity polycrystalline raw material 100g, 30mm thick about 18g anhydrous B 2 o 3 Put them in order, and finally place the crucible in the quartz tube as a whole, and vacuumize to 10 at room temperature. -2 Pa and sealed;

[0042] ④ Put the sealed quartz tube into the crystal growth furnace, and place the end with the seed crystal, flux and polycrys...

Embodiment 3

[0047] Descend Growth of Low Absorption Phosphorus, Germanium and Zinc Crystals

[0048] ① Design and manufacture a crystal growth furnace with three temperature zones with suitable gradients, which are divided into low temperature zone, gradient zone and high temperature zone, and the temperature gradient in the gradient zone is 7°C / cm;

[0049] ②Clean and dry the grown boron nitride crucible with deionized water, and coat the surface of the crucible with a carbon film;

[0050] ③Put the oriented phosphorus-germanium-zinc seed crystal into the crucible seed crystal groove, ZnF 2 and Ge 60g, pre-grown phosphorus germanium zinc high-purity polycrystalline raw material 120g, 30mm thick about 18g anhydrous B 2 o 3 Put them in order, and finally place the crucible in the quartz tube as a whole, and vacuumize to 10 at room temperature. -2 Pa and sealed;

[0051] ④ Put the sealed quartz tube into the crystal growth furnace, and place the end with the seed crystal, flux and polyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com