Hair styling device and temperature control system and method thereof

A temperature control system, styler technology, applied in the direction of hair curlers, hairdressing equipment, hair curling or perming devices, etc., can solve problems such as waiting for a certain time to use, hair overheating damage, rapid temperature changes, etc., to achieve heating speed Faster, less hair damage, less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

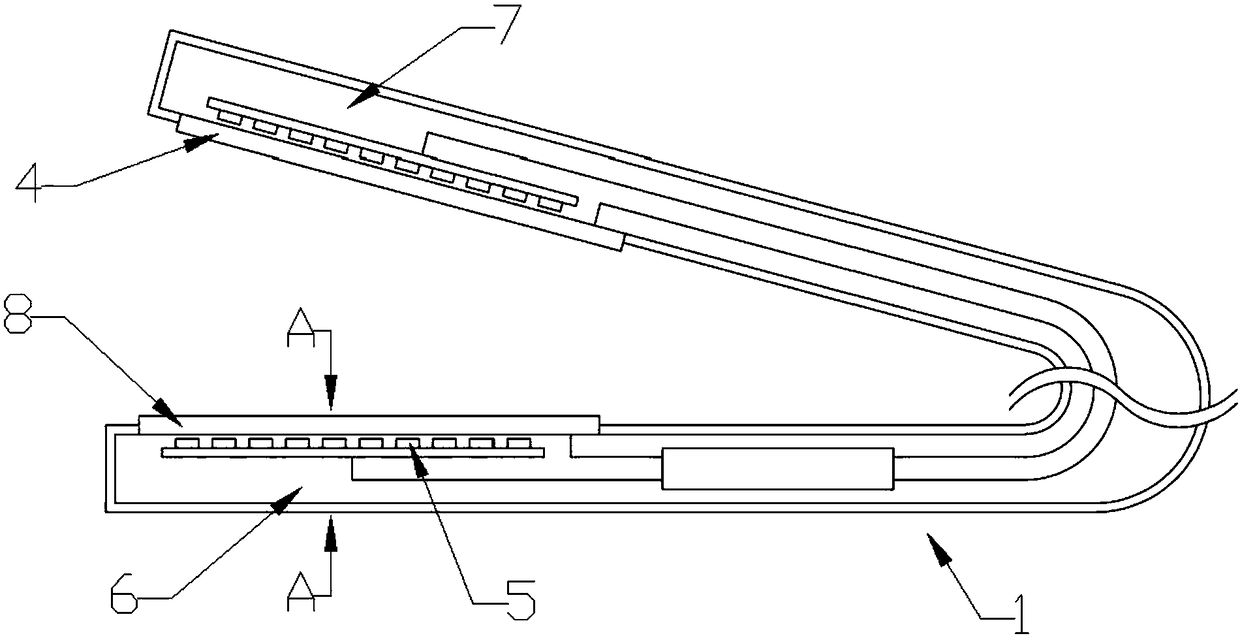

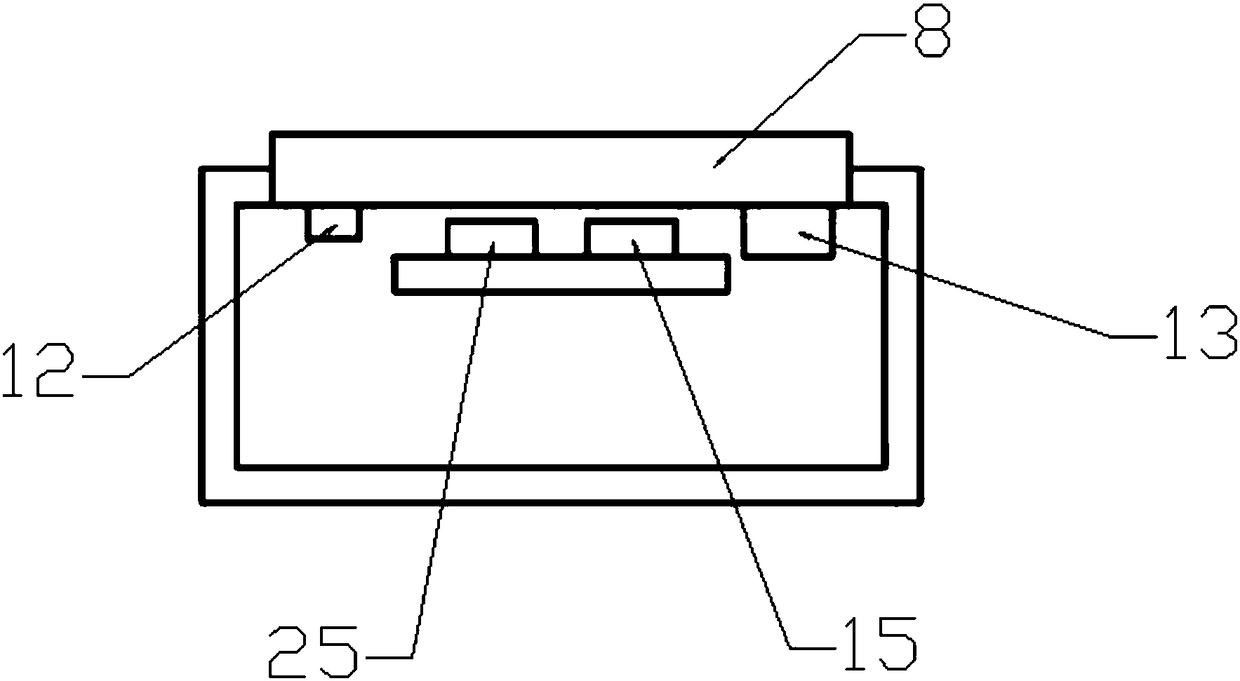

[0035] In order to solve the problems of inconvenient use and low efficiency of the traditional hair styler, Embodiment 1 of the present invention provides a hair styler which utilizes electromagnetic waves to heat and style hair. Electromagnetic wave heating is a new type of heating method, which has the characteristics of fast heating speed and good heating effect. The effectiveness of electromagnetic wave heating mainly depends on the degree of absorption of the heated object. The higher the absorption coefficient, the better the heating effect on the object. The absorption coefficient of different objects for electromagnetic waves of the same wavelength depends on the type of heated substance, the surface state, the wavelength of the radiation source, etc. The ratio of the radiation energy transmitted by a substance to the incident energy is called the transmittance. The transmittance varies with the nature and thickness of the material, and the effective penetration range...

Embodiment 2

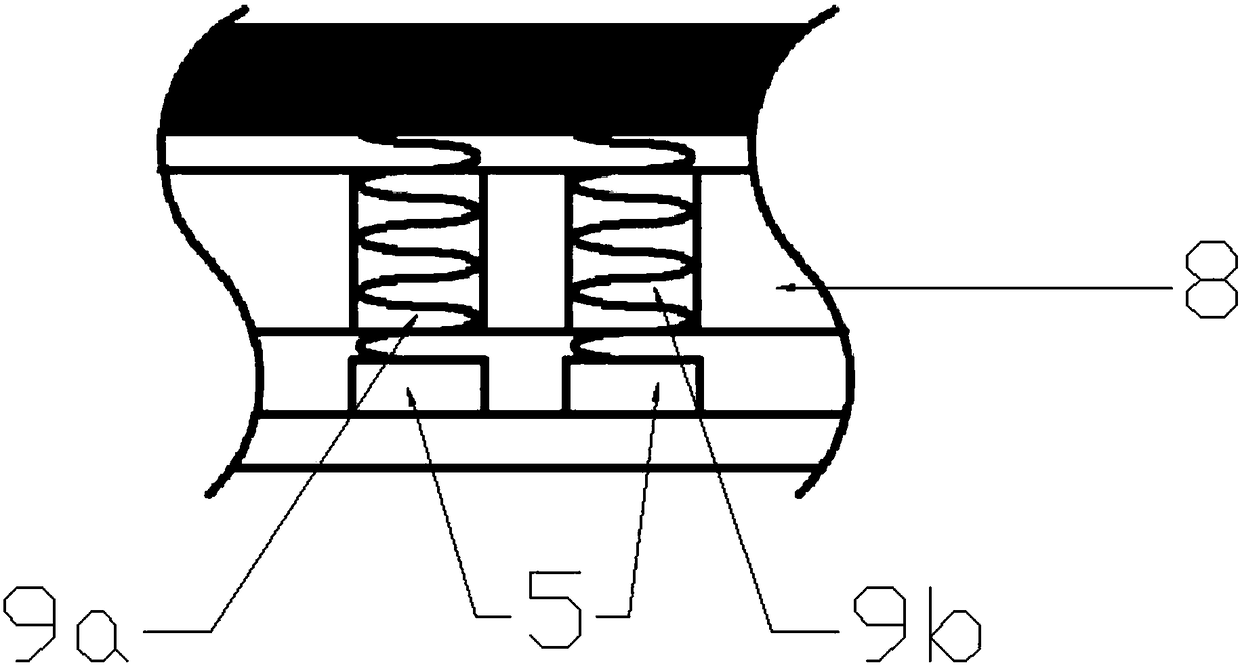

[0047] As shown in the figure, the difference between the second embodiment and the first embodiment is that the main body 1 of the clip structure includes a fixing groove 19, and the inner wall of the fixing groove 19 includes at least one flat part 18 for pressing hair. The planar component 18 can move in the fixing groove 19 relative to the groove surface of the fixing groove 19 , so that its surface is close to or away from the groove surface of the fixing groove 19 . This embodiment also includes at least one electromagnetic wave emitter disposed inside, and the electromagnetic wave emitter emits electromagnetic waves that can pass through the planar member 18 to heat the hair. The other parts of the second embodiment are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com