Method and equipment for printing 3D foods

A printing equipment and food technology, applied in the field of 3D food printing, can solve the problems of unreal-time control of the feed flow of food raw materials, low product resolution, and inability to stack, etc., to achieve intelligent flow and viscosity control, high printing resolution, and controllability temperature accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

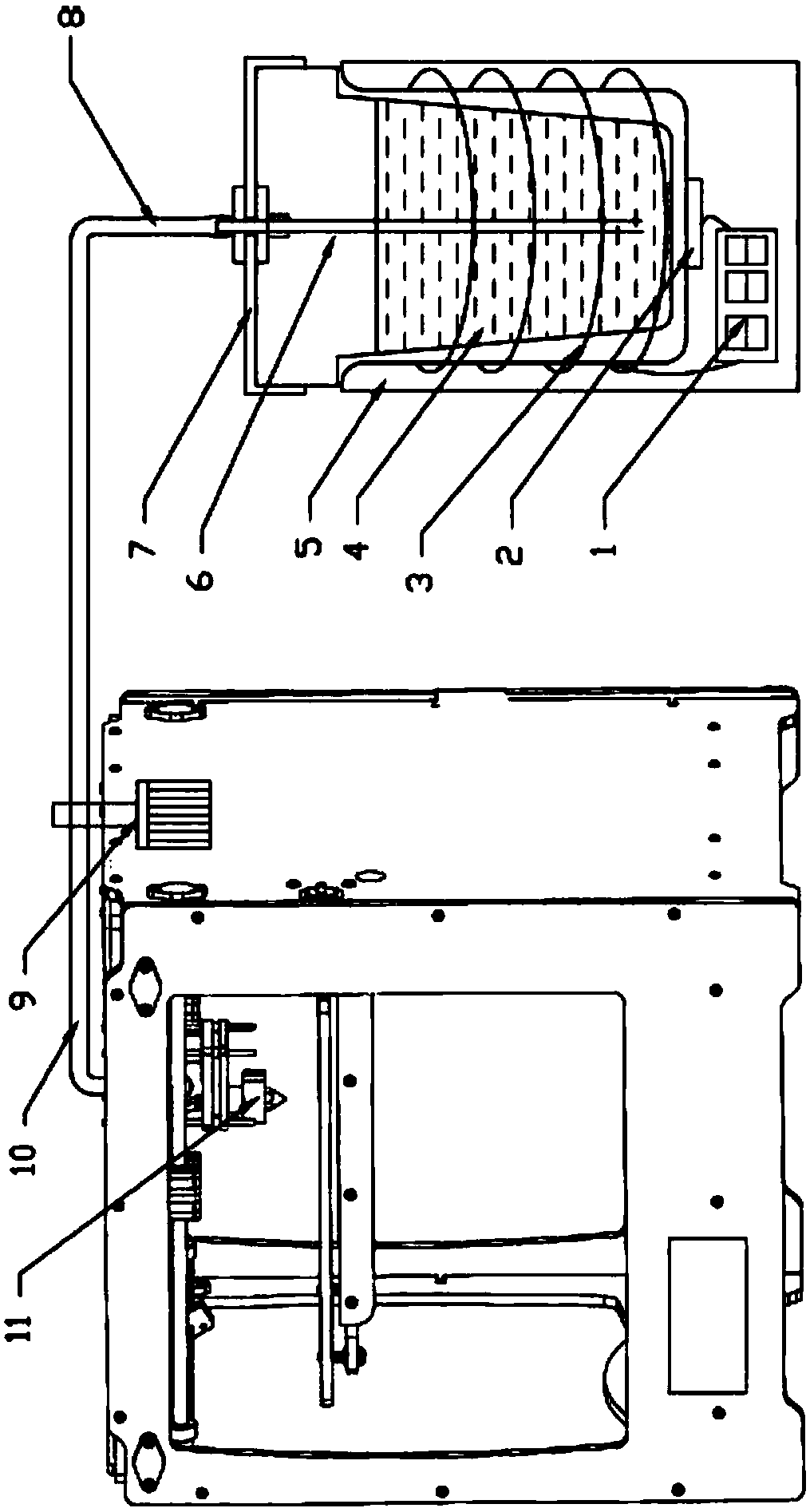

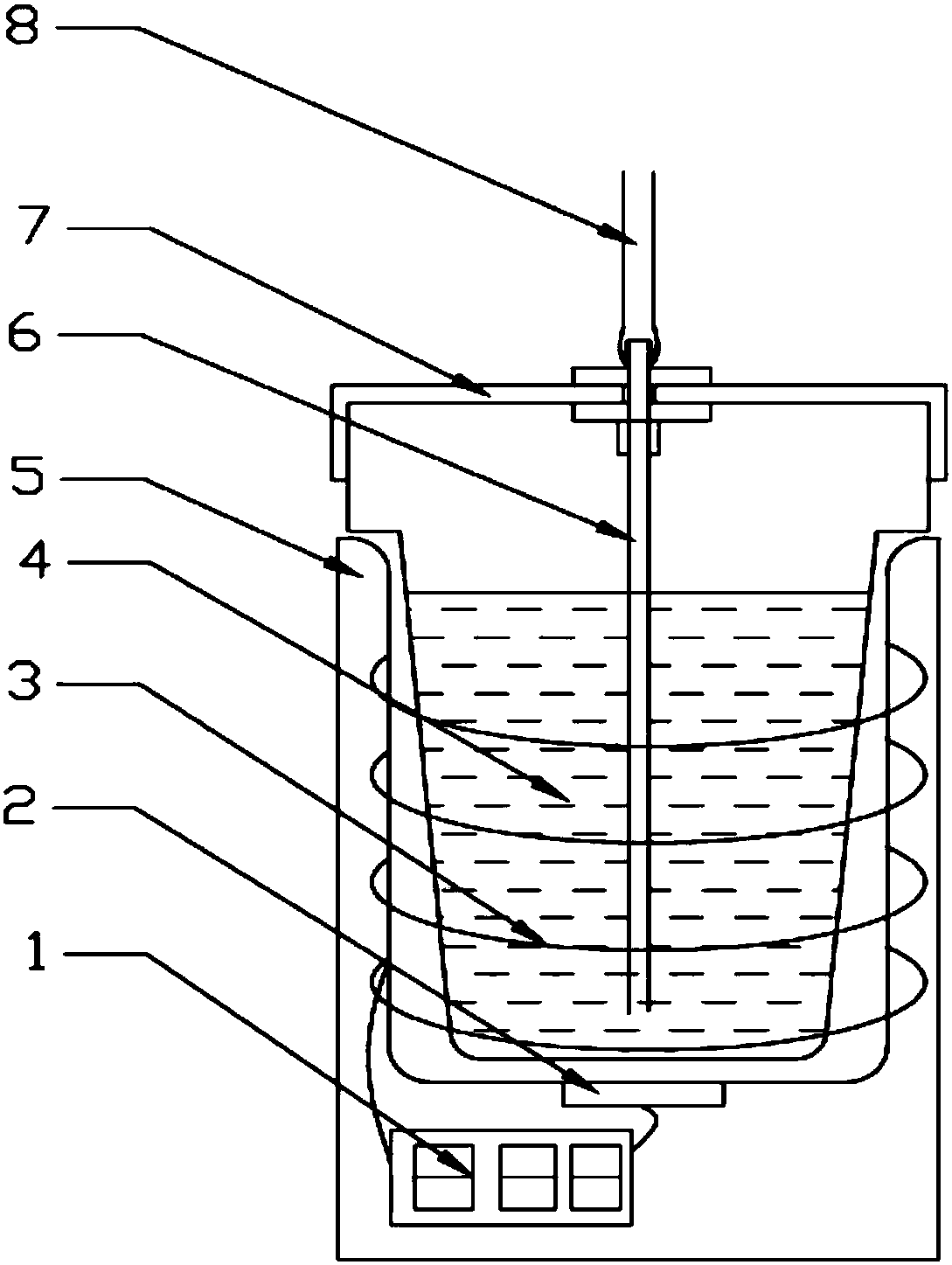

[0036] to combine Figure 1-Figure 3 As shown, the structure of the 3D food printing equipment is the same as that of the first embodiment.

[0037] The method of printing 3D chocolate using the above-mentioned 3D food printing equipment:

[0038]1) Put the chocolate into the container 4 of the feeding device, set the heating temperature in the intelligent control and display module 1 to 45°C on the external computer, and the intelligent control and display module 1 will start the heater 3 to heat the container 4 and keep it The temperature of container 4 is 45°C;

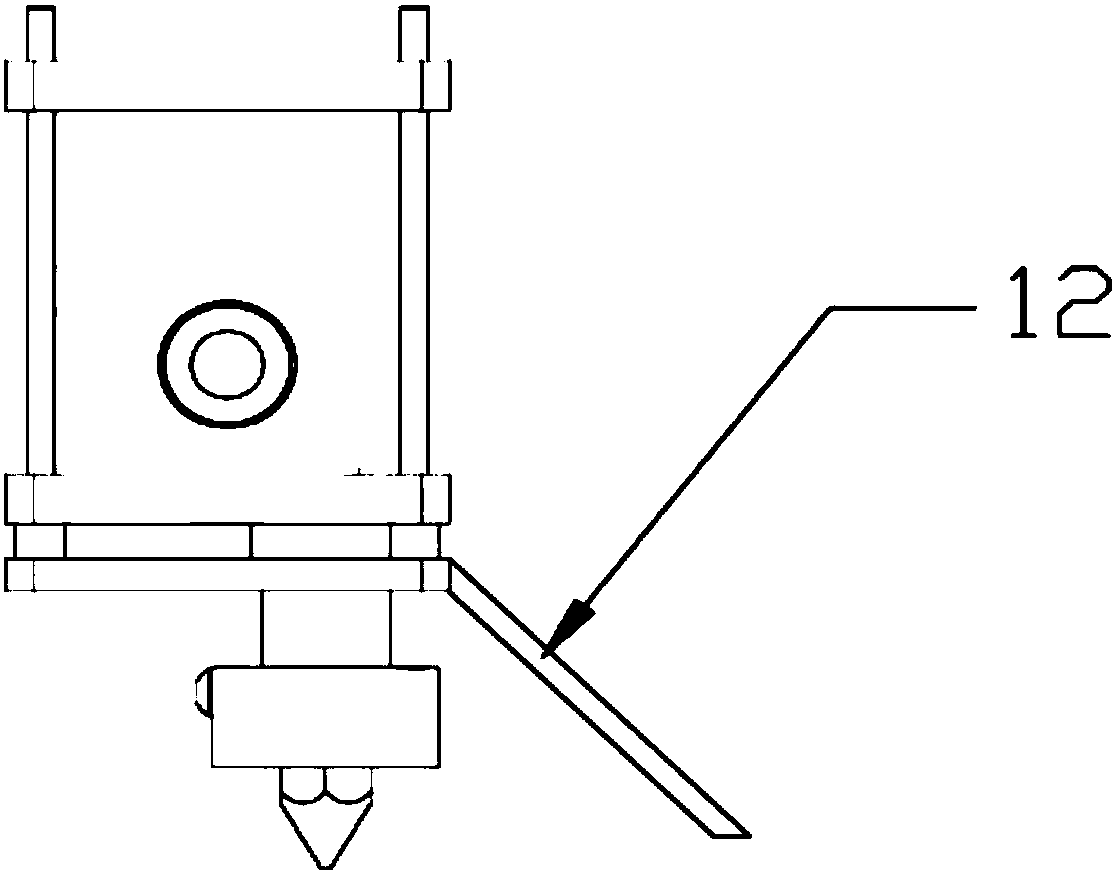

[0039] 2) After the chocolate is completely melted, transfer the target graphics to be printed to the computer, and the computer performs slice calculations based on the target graphics and then transmits the data to the 3D printer to print out the three-dimensional target graphics layer by layer with the melted chocolate slurry as the raw material, and print them on the computer Set the printing speed as V (unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com