Micro nano fiber vibration sensor based on hollow fiber

A vibration sensor, hollow-core fiber technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low reflectivity, expensive equipment, small size, etc., achieve small size, small cross-sensitivity, and improved The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

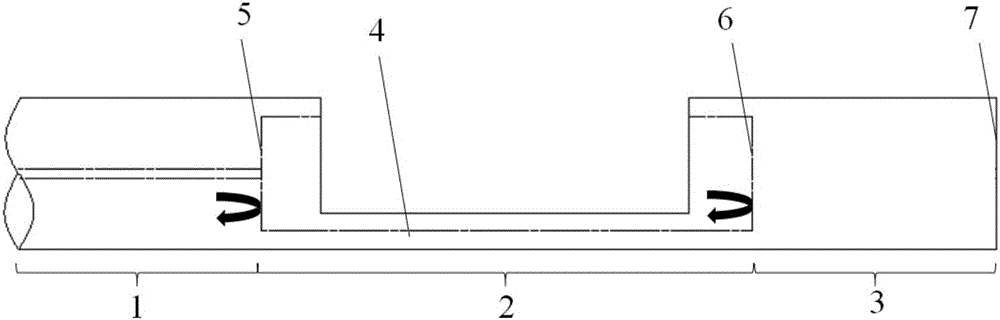

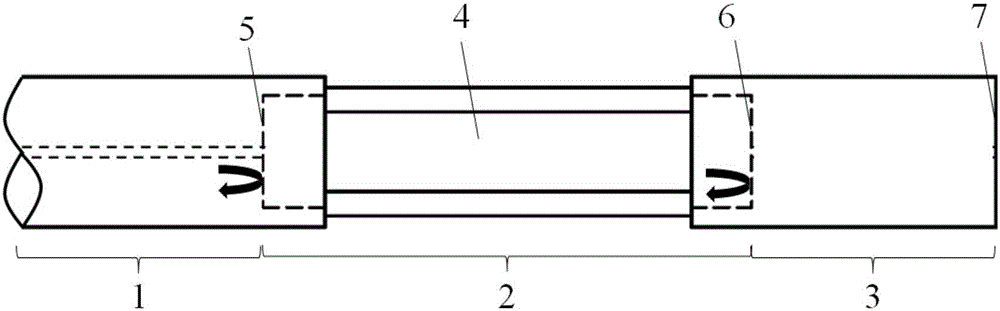

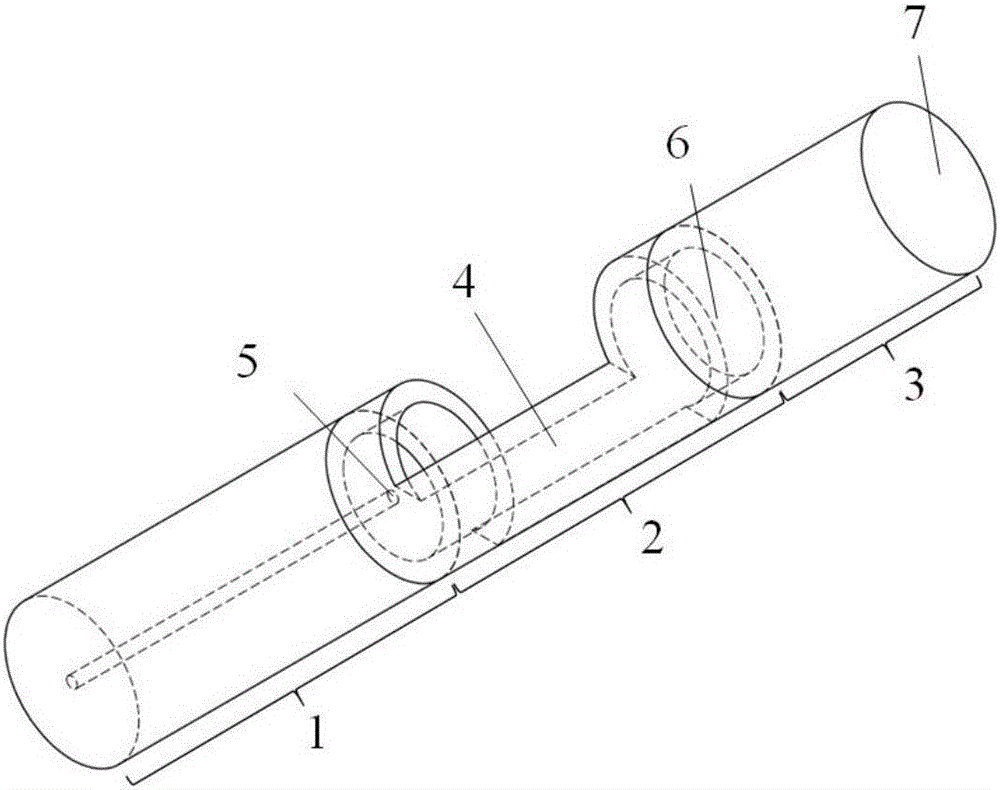

[0031] A micro-nano optical fiber vibration sensor based on femtosecond laser micromachining, comprising: a single-mode optical fiber 1, a hollow-core optical fiber 2, and a solid-core optical fiber 3; wherein, the femtosecond laser ablates the solid-core optical fiber 3 to form a cantilever 4, and the solid-core The optical fiber 3 is used as a mass block;

[0032] The single-mode optical fiber 1, the hollow-core optical fiber 2 and the solid-core optical fiber 3 are sequentially fused; the hollow-core optical fiber 2 is ablated by a femtosecond laser to form a cantilever beam 4, and the solid-core optical fiber 3 is used as a mass block.

[0033] The length of the hollow-core fiber 2 is 1000 μm, the outer diameter is the same as that of the single-mode fiber 1, which is 125 μm, the inner diameter is 93 μm, and the femtosecond laser ablation depth is 90 μm; the length of the solid-core fiber 3 is 3000 μm.

[0034] processing methods:

[0035] Step 1, the single-mode fiber 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com