Great-angle tilted fiber bragg grating mechanical vibration sensing array and system

A technology of tilting fiber gratings and fiber gratings, which is applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of very high requirements for instruments and equipment, and achieve the effects of not being prone to electromagnetic interference, unique and ingenious structure, and convenient demodulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

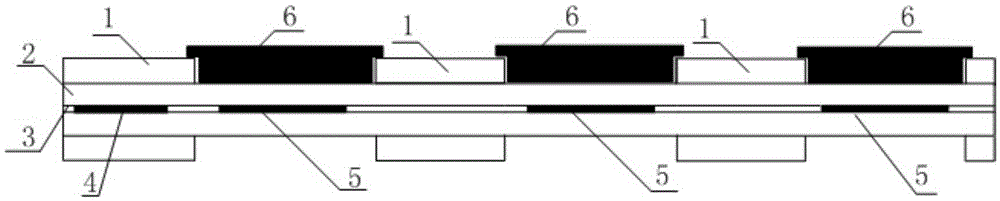

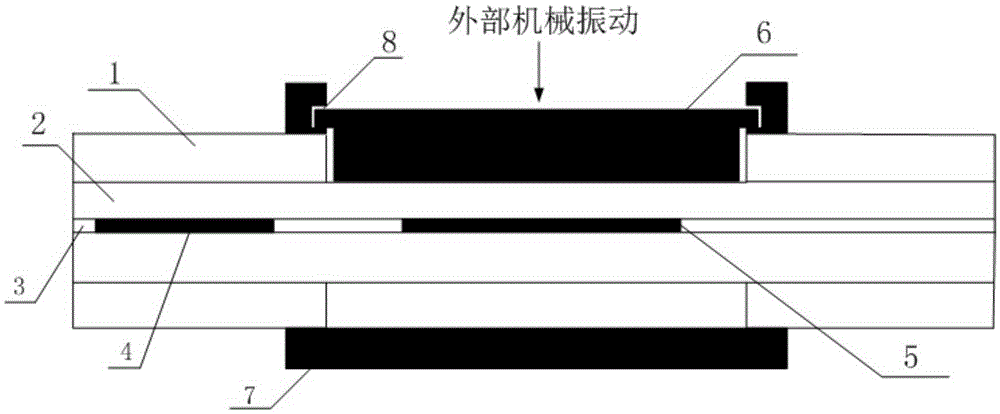

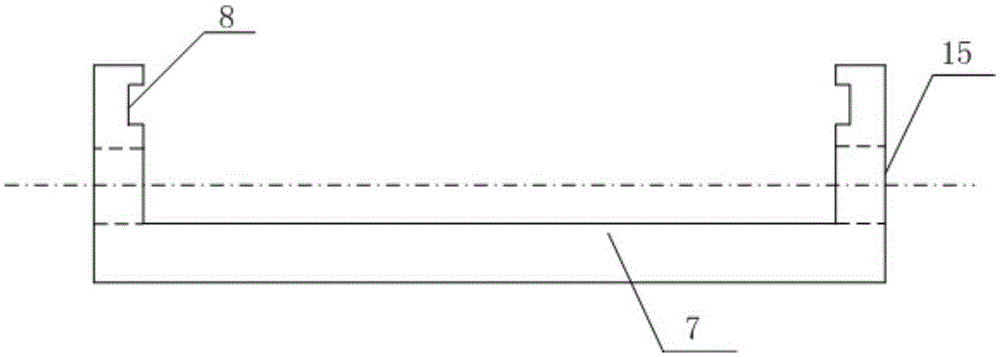

[0024] see figure 1 , a very large-angle tilted fiber grating vibration sensing array, including a fiber core 3, characterized in that: the front section of the fiber core 3 is provided with a 45° tilted fiber grating 4, and the 45° tilted fiber grating 4 is used as a maximum angle tilt The polarizer of the fiber grating vibration sensor; the angle between the inclined grating stripes of the 45° inclined fiber grating 4 and the cross-section of the optical fiber is 45°; the middle section of the optical fiber core 3 is provided with different maximum angles of N grating periods Fiber Bragg grating 5, a natural number of N≥1; each extremely inclined fiber Bragg grating 5 is used as a vibration sensing unit, the grating stripes of N extremely inclined optical fiber gratings 5 are parallel to each other, and each extremely inclined optical fiber grating 5 The included angles between the oblique grating stripes and the fiber cross-section are between 79° and 84°; see image 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com