Micro-machine magnetic field senor and application thereof

A magnetic field sensor and micromechanical technology, applied in the direction of the size/direction of the magnetic field, piezoelectric/electrostrictive/magnetostrictive devices, microstructure technology, etc., can solve the problem of increasing the sensitivity of the magnetic sensor and unable to eliminate the capacitive coupling signal Influence and other issues, to achieve the effect of reducing the resonance frequency, increasing the strength, and increasing the amount of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

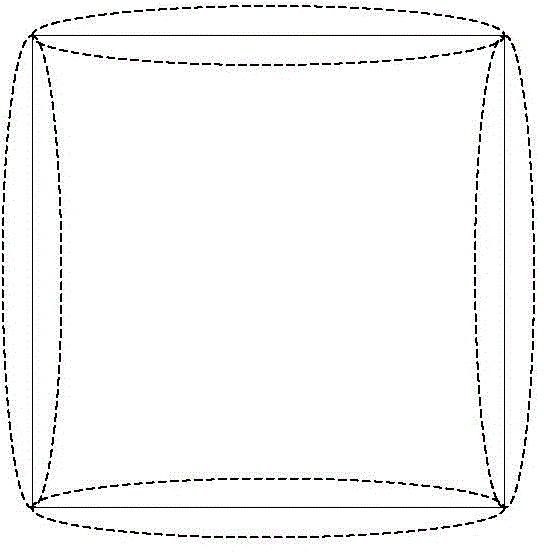

[0080] like Figure 2a to Figure 2c As shown, the present invention provides a micromechanical magnetic field sensor, which at least includes: a resonant oscillator and an insulating layer formed on the surface of the resonant oscillator, a grounded aluminum layer 2 and at least one layer of metal coil; The resonant oscillator includes: a resonant oscillator structure 31 , a main support beam 32 , a first anchor point 33 , a second anchor point 36 , an S-shaped folded beam 34 and a driving electrode 35 ; wherein, the resonant oscillator structure 31 includes four elastic beams. The elastic beam is used as the resonant oscillator structure 31 to reduce the resonant frequency of the entire magnetic sensor, so that the output modulated voltage signal can be easily demodulated by the demodulation chip.

[0081] The resonant oscillator structure 31 is an axisymmetric structure, and the symmetry axis of the resonant oscillator structure 31 includes at least a first symmetry axis and...

Embodiment 2

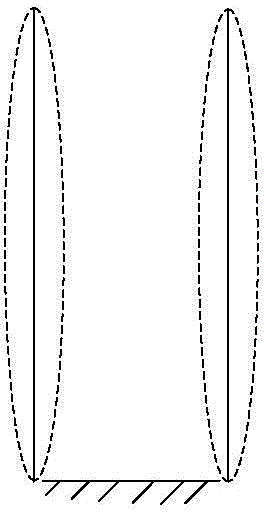

[0118] see Figure 3a and Figure 3b , this embodiment also provides a micro-mechanical magnetic field sensor, the technical solution of this embodiment is basically the same as that of Embodiment 1, the main difference is that the resonant oscillator structure described in Embodiment 1 is four elastic beams and four drive electrodes, and in this embodiment, the resonant oscillator structure is two elastic beams and two driving electrodes; and compared with the first embodiment, a second fixed support structure 38 is added in this embodiment. For the rest of the similarities of the micromachined magnetic field sensor (structure, manufacturing method, working principle and beneficial effects), please refer to the relevant description of the first embodiment, and will not repeat them here.

[0119] The resonant oscillator structure 31 is silicon carbide, and its first axis of symmetry is parallel to the long side or wide side of the first driving electrode. In this example, if...

Embodiment 3

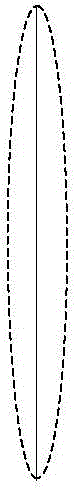

[0125] see Figure 4a and Figure 4b , this embodiment also provides a micro-mechanical magnetic field sensor, the technical solution of this embodiment is basically the same as that of Embodiment 1, the main difference is that the resonant oscillator structure described in Embodiment 1 is four elastic beams and four drive electrodes, and in this embodiment, the resonant oscillator structure is a single elastic beam and a single driving electrode; and compared with the first embodiment, the first fixed support structure 37 is added in this embodiment. For other similarities of the micromachined magnetic field sensor (structure, manufacturing method, working principle and beneficial effects), please refer to the relevant description of Embodiment 1, and details will not be repeated here.

[0126] One end of the first support structure 37 is connected to the S-shaped folded beam 34 close to the first anchor point 33, and the other end is connected to the S-shaped folded beam 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com