Method for preparing water coal slurry

A technology of coal water slurry and slurry storage, which is applied in the direction of combustion methods, block/powder fuel preparation, combustion equipment, etc., to achieve the effects of reducing energy consumption, high efficiency, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

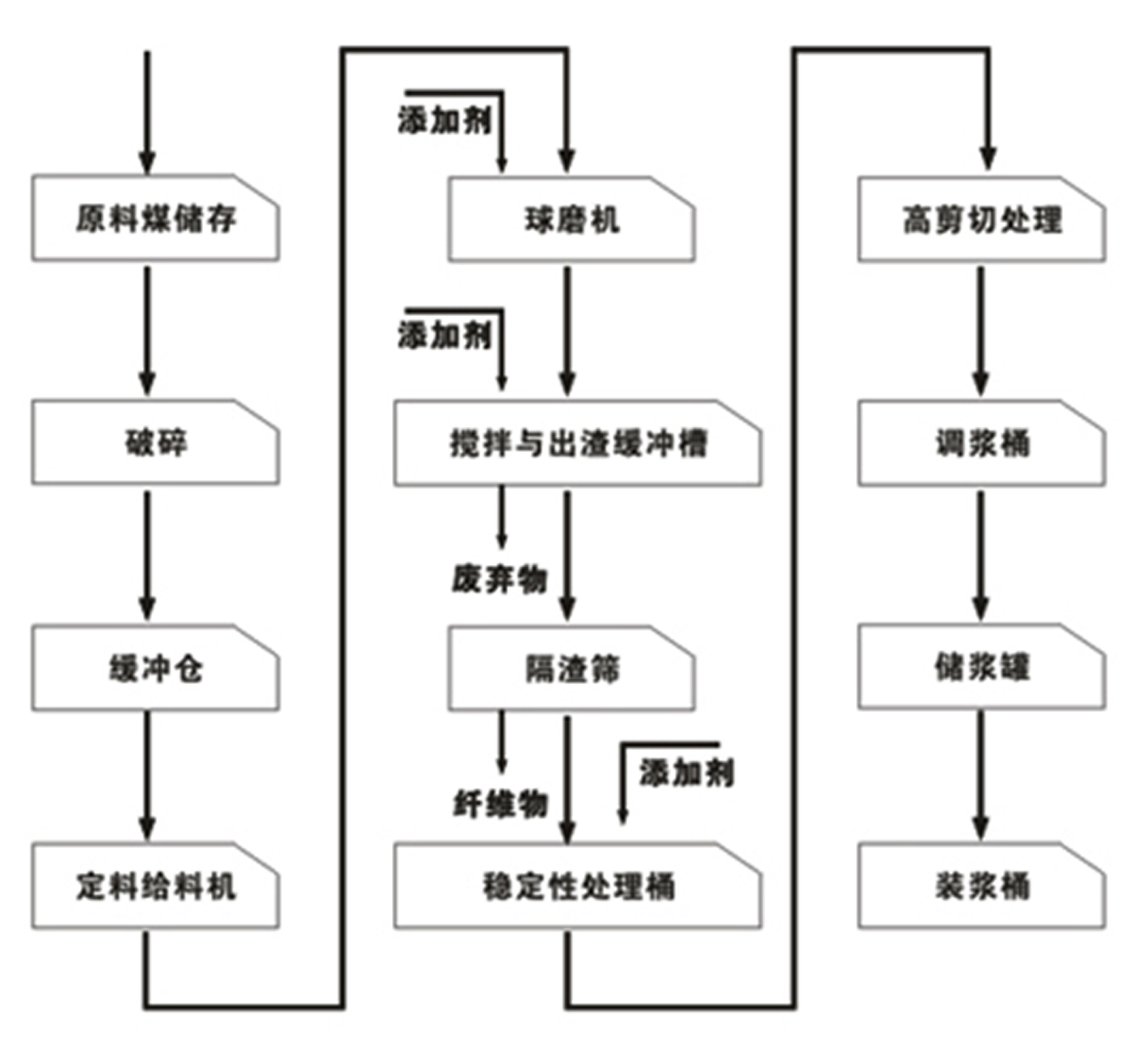

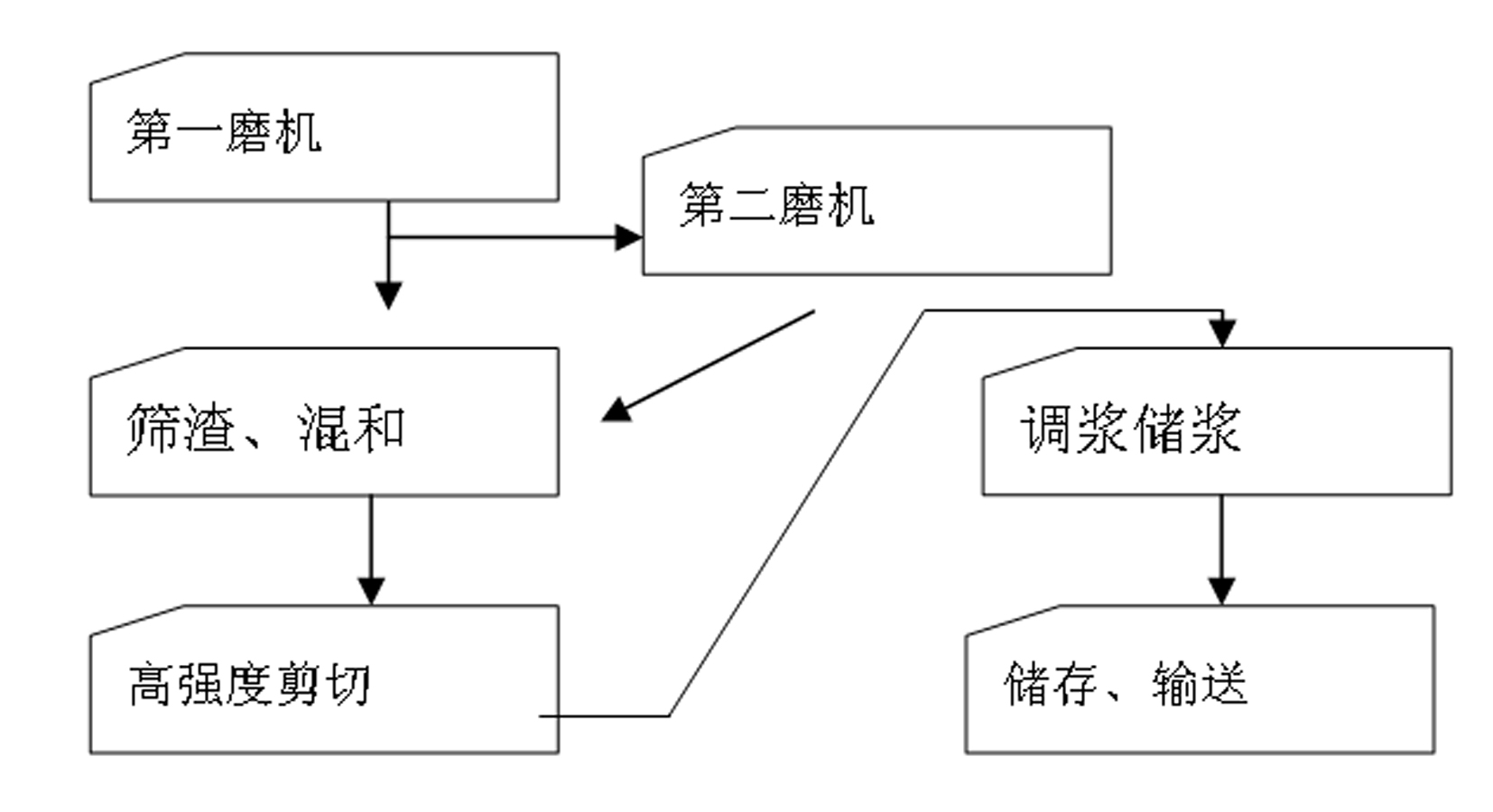

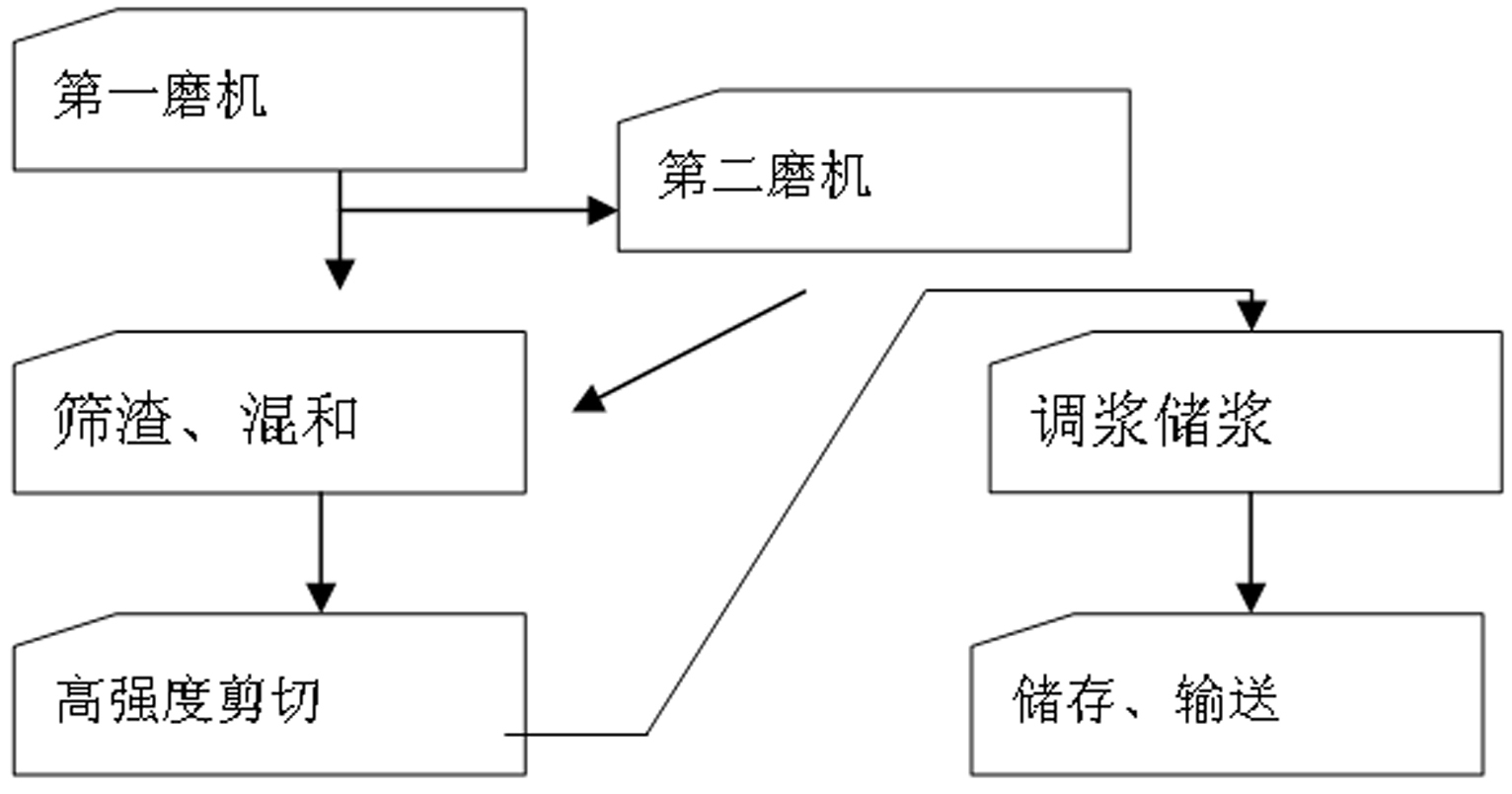

[0019] 1. The first preparation method of coal-water slurry, raw coal is crushed, buffer bin, feeder to the first ball mill, the first ball mill controls more than 90% of the ground particles to pass through a 325 mesh screen, and the first ball mill 20% of the weight of the discharged material is passed through the second ball milling, and the particles are ground to more than 90% and pass through a 600-mesh sieve. Or after mixing, it is subjected to high shear treatment, slag screening, slurry mixing, and slurry storage to obtain coal-water slurry. The solids content of the blended coal was increased to 65%.

[0020] 2. The second preparation method of coal-water slurry, raw coal is crushed, buffer bin, feeder to the first ball mill, the first ball mill controls more than 90% of the ground particles to pass through a 400-mesh sieve, and the first ball mill 30% of the weight of the discharged material is passed through the second rod mill, and the particles are ground to mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com