Reciprocating type rack fabric distributor

A kind of distributing machine, reciprocating technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as inability to work and difficult to continuous, and achieve the effect of improving work efficiency and reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

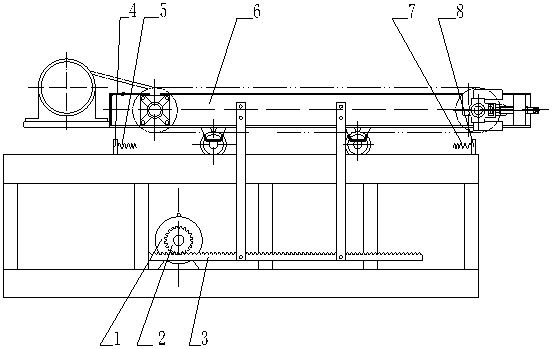

[0012] figure 1 Among them, the motor 1 is fixed on the frame made of channel steel, the gear 2 is fixed on the shaft of the motor 1, the gear 2 cooperates with the rack 3, the rack 3 is connected with the belt conveyor 6 through an angle iron, and the lower part of the belt conveyor 6 is installed The steamboat is placed on the frame that channel steel is made behind, and belt conveyor can move back and forth under the drive of tooth bar 3. The frame is provided with a front travel switch 8 and a rear travel switch 4 for controlling the moving distance of the belt conveyor 6 . The front travel switch 8 is provided with a front spring 7; the rear travel switch 4 is provided with a rear spring 5.

[0013] When working, the motor 1 runs, and the gear 2 fixed on the shaft drives the rack 3 matched with the gear 2 to move back and forth, and the rack 3 moves back and forth to drive the belt conveyor 6 as a whole to move back and forth. The moving distance of belt conveyor 6 dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com