AGV trolley for recycling wave soldering fixture

A wave soldering and trolley technology, applied in the direction of motor vehicles, vehicle position/route/height control, non-electric variable control, etc., can solve the problems of high labor intensity, occupying workshop space, and limited workshop space, so as to improve production efficiency , Reduce labor intensity, reduce the effect of equipment quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

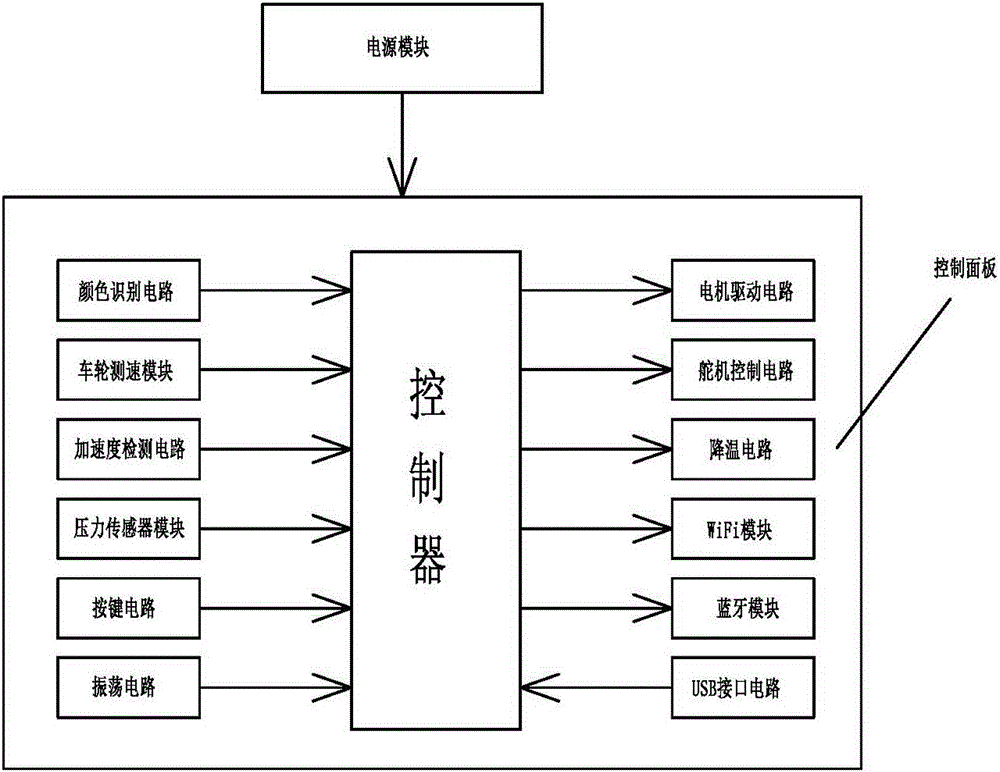

[0040] Combine now Figure 1 to Figure 16 As shown, a kind of recycling wave soldering fixture AGV trolley of the present invention,

[0041] Described USB interface circuit comprises USB interface J1, TVS diode D3, TVS diode D4, TVS diode D5 and resistor R5, 1 pin of USB interface J1 is connected with one end of resistor R5, the other end of resistor R5 Connect to 5V power supply, connect pin 1 of USB interface J1 to the positive pole of TVS diode D5, pin 3 of USB interface J1 to the positive pole of TVS diode D4, pin 2 of USB interface J1 to the positive pole of TVS diode The positive pole connection of D3, the 3 pins and 2 pins of the USB interface J1 are respectively connected with the 20 pins and 19 pins of the processor U of the model K60N512, the 4 pins of the USB interface J1, the negative pole of the TVS diode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com