Ore grinding flotation silicon-removing method of bauxite

A bauxite and flotation technology, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of alumina, increase of classification process, over-grinding and polarization, etc., so as to improve flotation recovery rate and improve coarse The effect of particle size content and beneficiation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The diaspore-type bauxite was used as the test ore sample. The chemical composition is shown in Table 1, and the mineral composition is shown in Table 2.

[0020] Table 1 Chemical composition of diaspore bauxite

[0021]

[0022] Table 2 Mineral phase composition of diaspore-type bauxite

[0023]

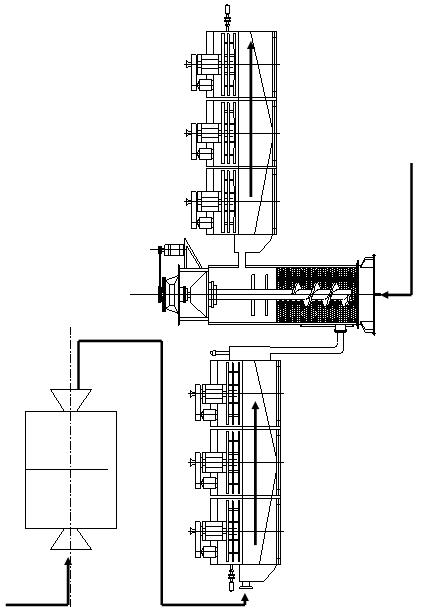

[0024] Process equipment: grid-type ball mill is used for primary grinding, vertical stirring mill is used for secondary grinding, flotation unit is external aerated mechanical stirring flotation machine, 2 flotation machines for primary flotation, 4 for secondary flotation Flotation machine.

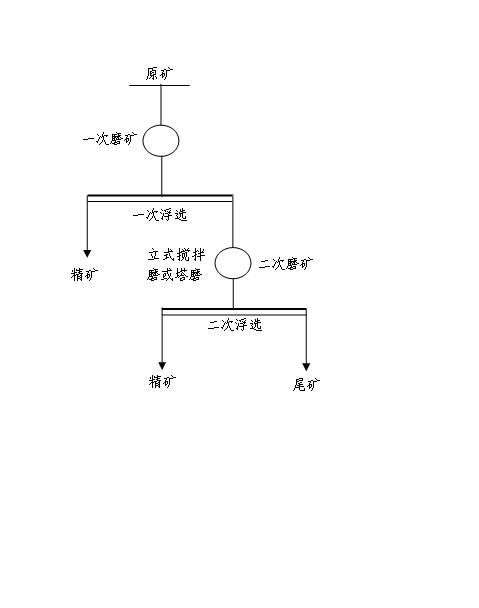

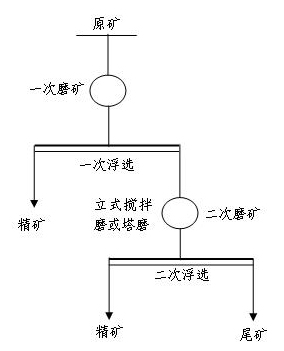

[0025] Process flow: see process flow chart (attached figure 1 ).

[0026] Process parameters: the fineness of the first stage grinding is 70.58%, and the gas input of the vertical stirring mill is 5m 3 / h, the pharmaceutical system is a conventional positive flotation reagent system.

[0027] Process index: see table 3.

[0028] Table 3 Example 1 Flotation Index

[0029]

[0030] It can be seen f...

Embodiment 2

[0036] Taking gibbsite mixed bauxite as the test ore sample, its chemical composition is shown in Table 5, and the mineral composition is shown in Table 6.

[0037] Table 5 Chemical composition of gibbsite mixed bauxite

[0038] Table 6 Mineral phase composition of gibbsite mixed bauxite

[0039]

[0040] Process equipment: grid-type ball mill is used for primary grinding, vertical stirring mill is used for secondary grinding, flotation machine is external aerated mechanical stirring flotation machine, 1 flotation machine for primary flotation, 3 for secondary flotation Flotation machine.

[0041] Process flow: see process flow chart (attached figure 1 ).

[0042] Process parameters: the fineness of the first stage grinding is 30.58%, and the gas inlet of the vertical stirring mill is 3.5m 3 / h, the reagent system is a conventional anti-flotation reagent system.

[0043] Process index: see Table 7.

example 2

[0044] Table 7 Example 2 Flotation Index

[0045]

[0046] It can be seen from Table 7 that through the selection of the technological indicators of the invention patent, a good indicator with a concentrate aluminum-silicon ratio of 7.72 and a yield of 91.33% was obtained.

[0047] The product was screened and analyzed, and the screening results are shown in Table 8.

[0048] Table 8 Example 2 product screening analysis

[0049]

[0050] It can be seen from Table 8 that the content of -21μm in the concentrate is only 25.04, while the content of -21μm in the conventional process flow is about 50%, which greatly reduces the fine-grain level in the concentrate; the content of -21μm in the tailings is only It is 33.59%, and the content of fine particle grade has dropped significantly, laying a good foundation for subsequent settlement and product processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com