New process for preparing high quality Co3O4

A high-quality technology of cobalt tetroxide, applied in cobalt oxide/cobalt hydroxide and other directions, can solve the problems of difficult control of product morphology and particle size, inability to meet manufacturing, and unstable production, and to simplify process control and equipment maintenance and improvement. The effect of production efficiency and single appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

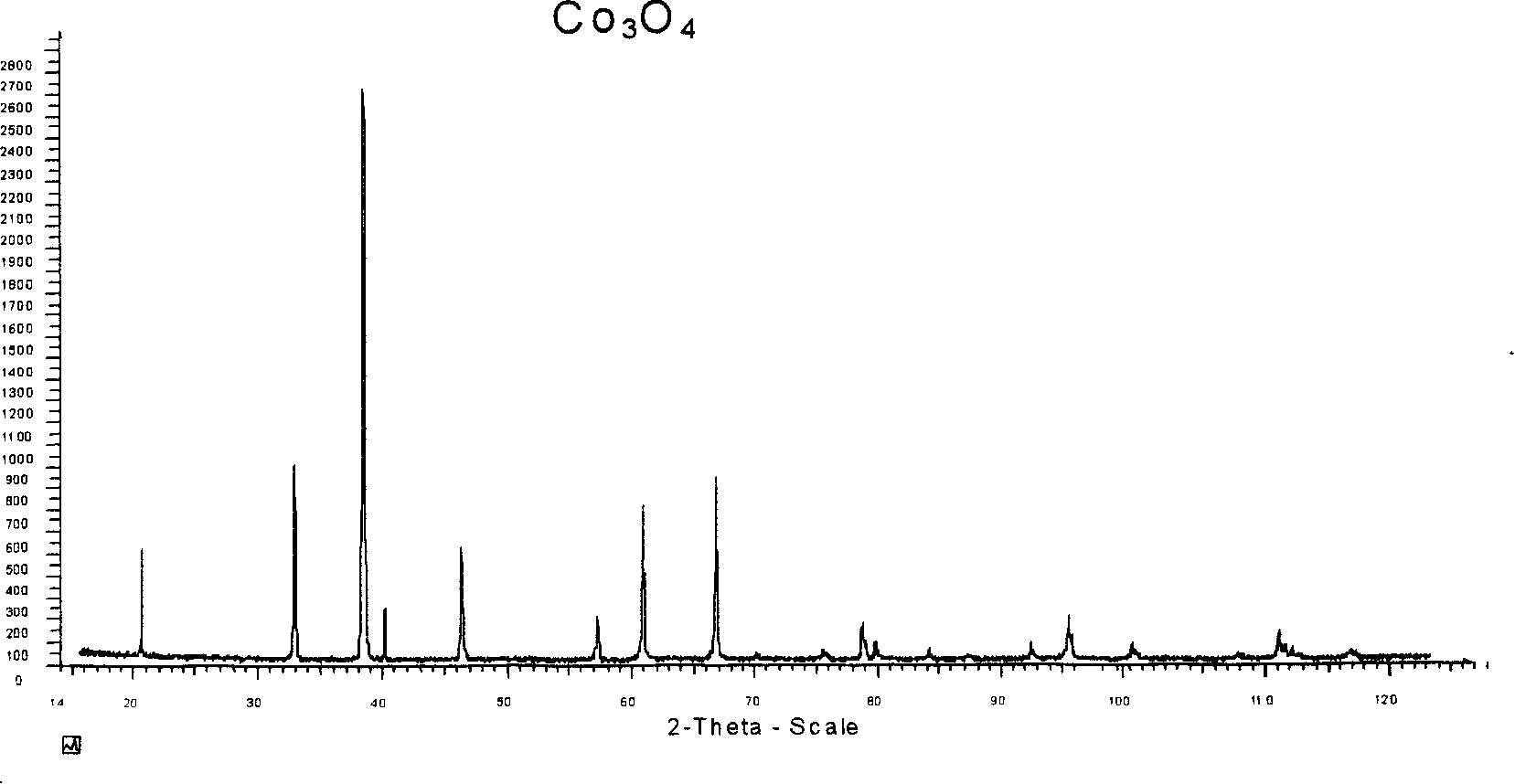

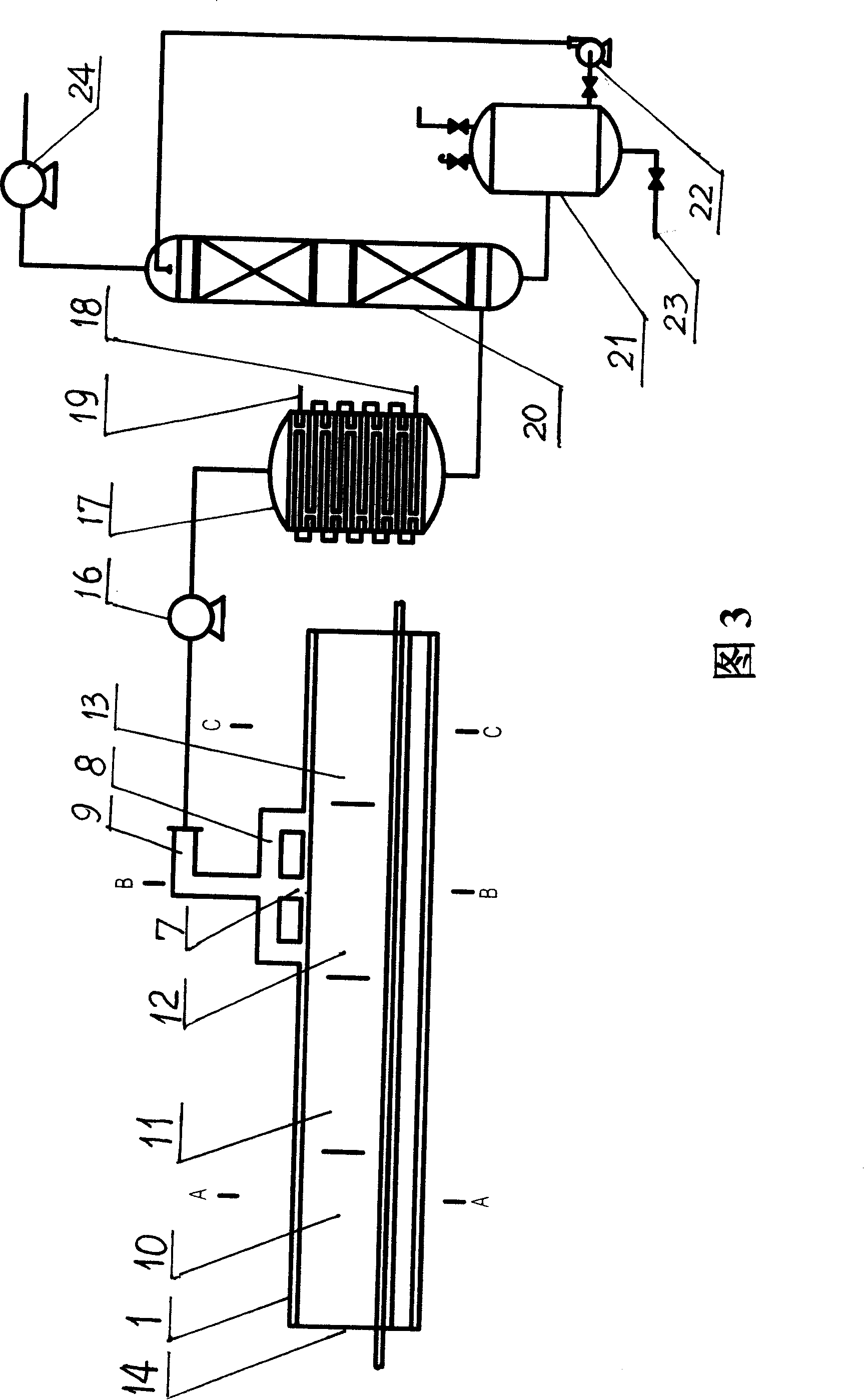

[0027] Cobalt salt CoCl containing water of crystallization 2 ·xH 2 O or Co(NO 3 ) 2 ·xH 2 O or CoSO 4 ·xH 2 O or Co(AC) 2 ·xH 2 O, (x=1~6) is filled in a corundum crucible, pushed into the special reaction furnace of the present invention, raised to 850°C at a heating rate of 5°C / min and calcined for 15 hours, so that the granular crystal form can be further grown completely, and finally Collected by natural cooling to obtain a powder with an average particle size of 3-8μm and a tap density of 2.2-2.8g / cm 3 , ray diffraction phase analysis shows that the powder is a pure phase of Co 3 o 4 ; The gas generated during roasting is introduced into the condenser by the induced draft fan to be cooled and pre-collected, and then passed into a special absorption device to completely absorb and make acid. As a by-product, the obtained powder can fully meet the requirements for the preparation of lithium-ion secondary batteries. Requirements for the cathode material lithium co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com