Lean ore two-stage dry magnetic separation and three-stage crushing processing technology

A dry magnetic separation and processing technology, applied in grain processing, etc., can solve the problems of excessive waste of chemicals, waste of production resources, large amount of ore returning sand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

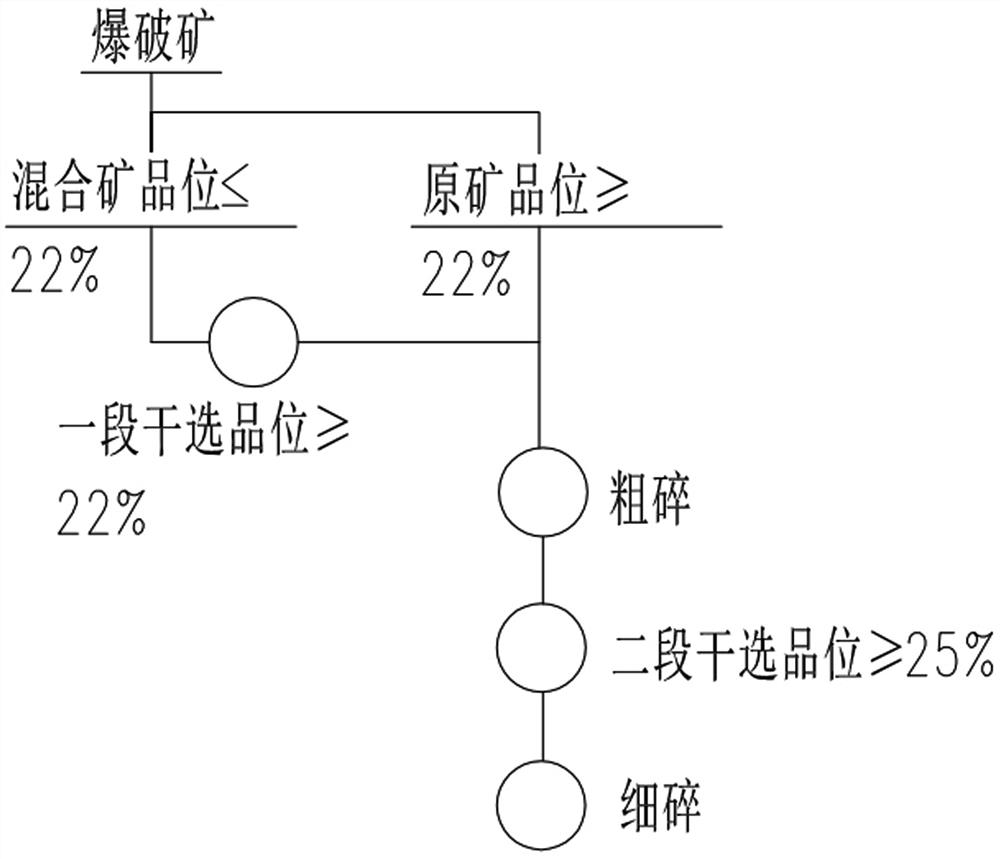

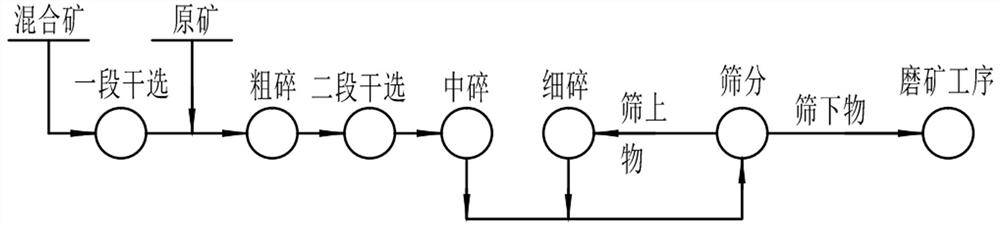

Embodiment 1

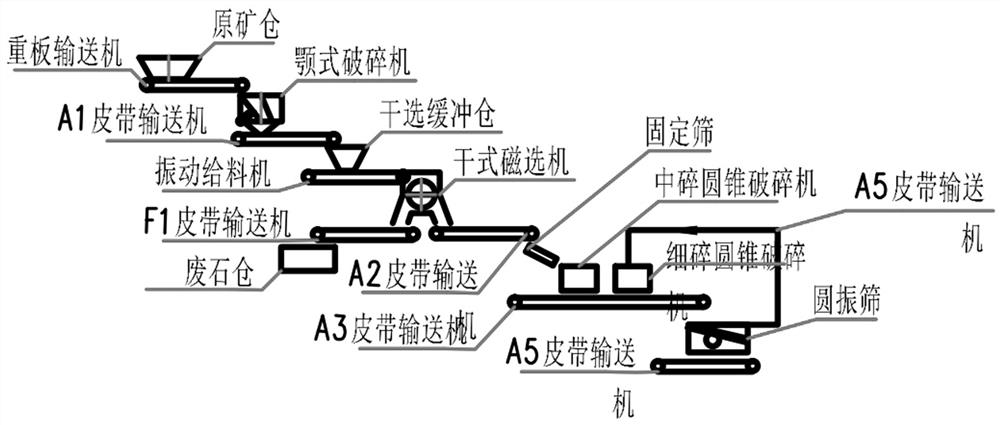

[0057]The maximum particle size of magnetite is 0.1-0.2mm, the smallest is less than 0.02mm, generally 0.02-0.08mm, the mineral content is generally 20%-40%, the ore crystal particle size is finer, and the selectivity is worse. For this kind of low-grade iron ore, the grinding grade is between 22% and 26%. Two-stage dry magnetic separation and three-stage crushing process are adopted. After crushing, the particle size is <256mm, and it enters the second-stage dry magnetic separation. The high-grade ore is selected and sent to the secondary crusher for crushing. The ore particle size is reduced to <70mm. Screening and screening, the final particle size of the crushed ore product is <12mm, and it is dissociated to a suitable particle size to ensure that the ore entering the grinding reaches a reasonable grade. The two-stage dry magnetic separation and three-stage crushing process is adopted, and the dry magnetic separator is used to improve the ore grade and remove waste rocks. ...

Embodiment 2

[0060] A two-stage dry magnetic separation process for lean ore, the specific steps are as follows.

[0061] The ore with a grade ≥ 24% produced after blasting is transported to the coarse crushing process, and the mixed ore with a grade < 24% is transported to the first stage of the dry-type magnetic separator in the stope for magnetic separation. One-stage dry separation magnetic separator model CTDG1516, (drum diameter×drum length is 1500×1800mm, belt width is 1600mm, belt speed is 1~2.5m / s, the magnetic induction intensity of the drum table sorting area is -600mT, and the separation particle size is 0~350mm , The motor adopts YYF2-280M-655kW380V frequency conversion motor, equipped with frequency converter. After a stage of dry separation, the ore with a grade ≥ 24% is transported to the coarse crushing process to increase the ore output.

[0062] The ore obtained by the above steps enters the coarse crushing operation. After crushing, the ore enters the second-stage dry s...

Embodiment 3

[0066] A two-stage dry magnetic separation and three-stage crushing process for lean ore, the specific steps are as follows.

[0067] The ore with a grade ≥ 24% produced after blasting is transported to the coarse crushing process, and the mixed ore with a grade < 24% is transported to the first stage of the dry-type magnetic separator in the stope for magnetic separation. One-stage dry separation magnetic separator model CTDG1516, drum diameter×drum length 1500×1800mm, belt width 1600mm, belt speed 1~2.5m / s, magnetic induction intensity of drum table sorting area: -600mT, sorting particle size 0~350mm, motor adopts YYF2-280M-655kW380V frequency conversion motor, equipped with frequency converter. After a stage of dry separation, the ore with a grade ≥ 24% is transported to the coarse crushing process to increase the ore output.

[0068] The ore obtained by the above steps enters the coarse crushing operation. After crushing, the ore enters the second-stage dry separation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com