Inert ceramet anode for electrolyzing molten salt and its prepn

A technology of cermets and inert anodes, applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of metal phase overflow and uneven distribution, poor thermal shock resistance, poor conductivity, etc., and achieve improved electrolyte corrosion resistance and sintering The effect of convenient performance and good sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] SnO 2 -NiFe 2 o 4 / Ni-Cu-Co cermet inert anode.

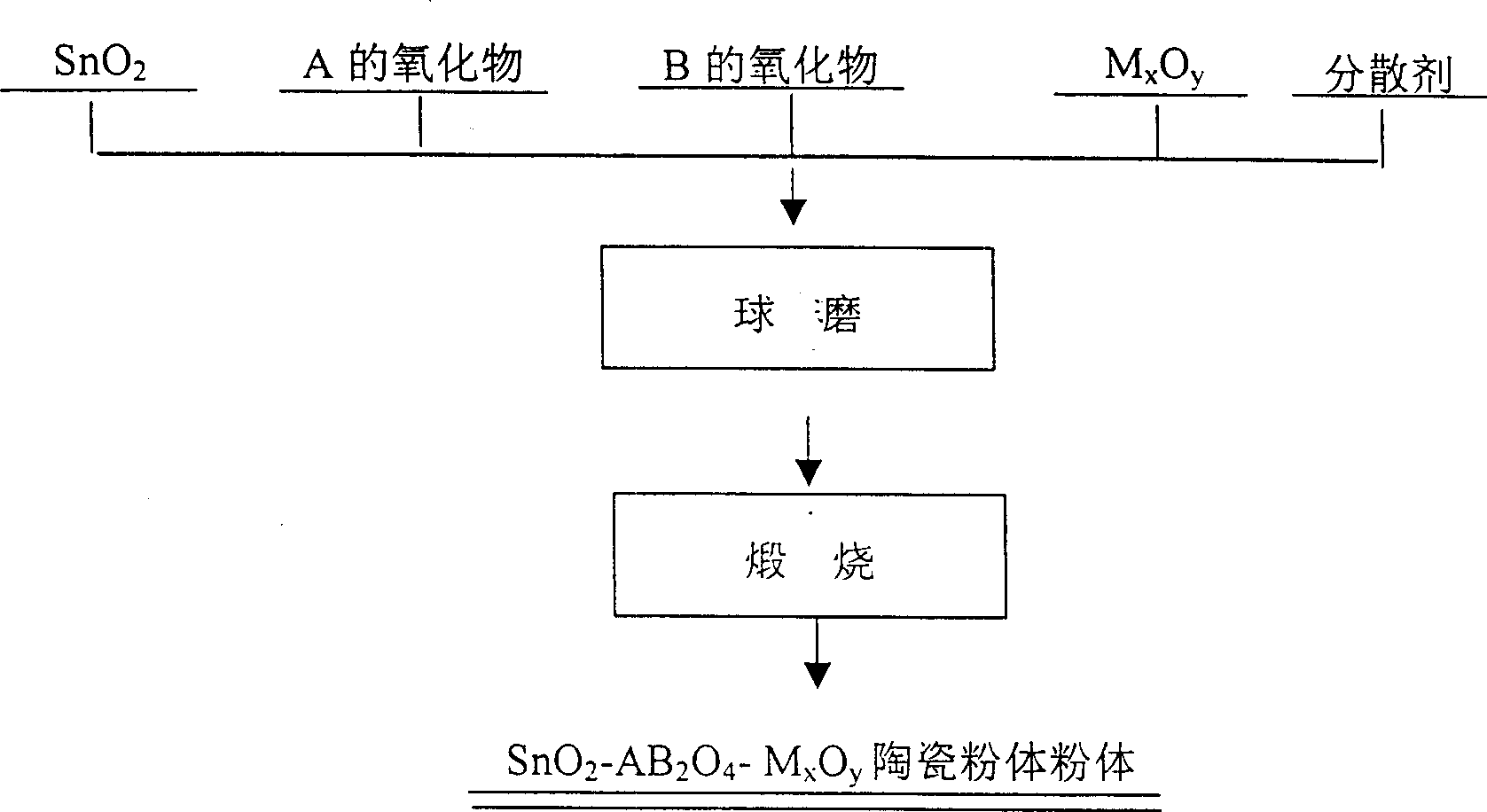

[0028] ① Prepare ceramic powder, press figure 1 The technical process is carried out, the raw materials in Table 1 are added to industrial alcohol as a dispersant, ball milled for 8 hours, and calcined at 1200 ° C for 8 hours to obtain ceramic powder with an average particle size of 3.31 μm. X-ray diffraction phase analysis shows that the ceramic powder contains SnO 2 and NiFe 2 o 4 Two phases; the obtained ceramic matrix has good corrosion resistance, has semiconductor properties at the temperature of aluminum electrolysis, and is used as the powder raw material of the ceramic matrix of the cermet inert anode.

[0029] raw material

Mass percentage (%)

SnO 2

50.00

f 2 o 3

36.58

NiO

13.42

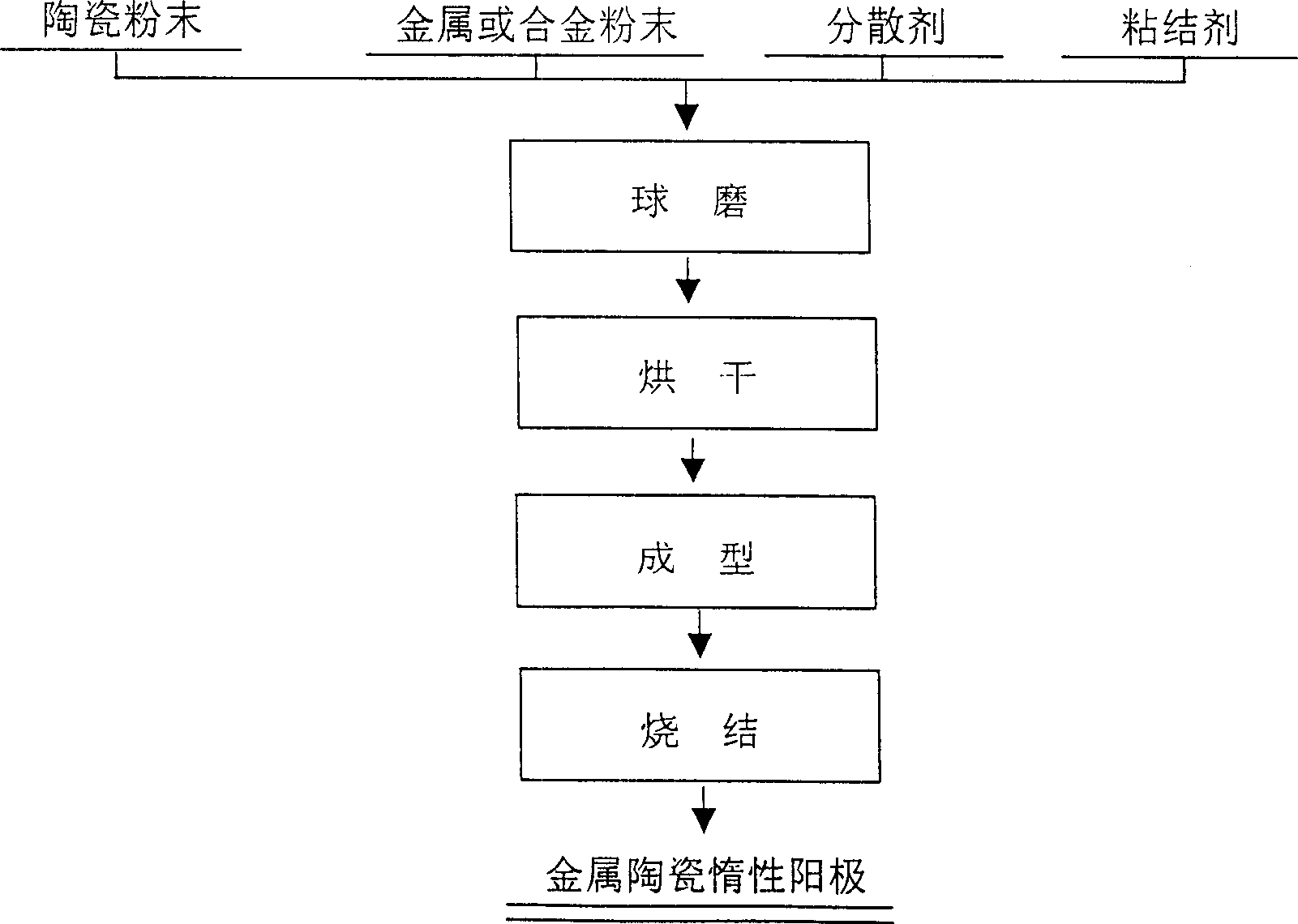

[0030] ②Preparation of cermet inert anode, according to figure 2 The technical process is carried out, the raw materials in Table 2 are used as the dispersant of...

Embodiment 2

[0033] SnO 2 -NiFe 2 o 4 -Sb 2 o 3 / Ni-Cu-Cr cermet inert anode

[0034] ① Prepare ceramic powder, press figure 1The process flow is carried out. The raw materials in Table 3 are treated with industrial alcohol as a dispersant, ball milled for 8 hours, and calcined at 1200°C for 8 hours to obtain ceramic powder with an average particle size of 3.11 μm. X-ray diffraction phase analysis shows that the ceramic powder mainly contains SnO 2 and NiFe 2 o 4 two phases. The obtained ceramic substrate has good corrosion resistance, has semiconducting properties at the aluminum electrolysis temperature, and has good electrical conductivity, and can be used as a ceramic powder raw material for a cermet inert anode.

[0035] raw material

Mass percentage (%)

SnO 2

48.00

f 2 o 3

36.58

NiO

13.42

Sb 2 o 3

2.00

[0036] ②Preparation of cermet inert anode, according to figure 2 The technical process is...

Embodiment 3

[0039] SnO 2 -NiAl 2 o 4 -CuO / Ni-Cu-Ag cermet inert anode

[0040] ① Prepare ceramic powder, press figure 1 The process flow is carried out. The raw materials in Table 5 are treated with industrial alcohol as a dispersant, ball milled for 8 hours, and calcined at 1300° C. for 8 hours to obtain a ceramic powder with a thickness of 4.11 μm. X-ray diffraction phase analysis shows that the ceramic powder mainly contains SnO 2 and NiAl 2 o 4 two phases. The obtained ceramic matrix has good corrosion resistance, has semiconducting properties at the aluminum electrolysis temperature, and can be used as a ceramic powder raw material for the cermet inert anode.

[0041] raw material

Mass percentage (%)

SnO 2

50.00

al 2 o 3

27.71

NiO

20.29

CuO

2.00

[0042] ②Preparation of cermet inert anode, according to figure 2 The technical process is carried out. The raw materials in Table 6 are used as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com