Combination cement grinding system

A combined grinding and cement technology, applied in cement production, grain processing, etc., can solve problems such as over-grinding, excessive fine powder in cement mills, and increased Taiwan production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

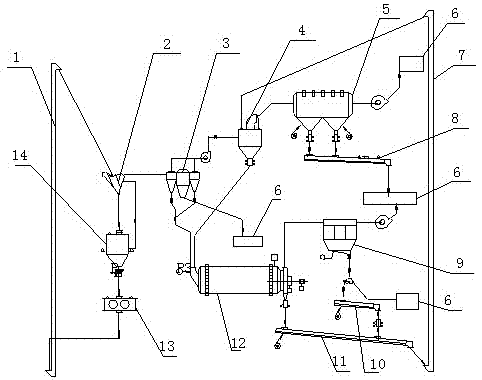

[0012] Such as figure 1 As shown, the cement combined grinding system is an automatic control system. The cement combined grinding system includes a hoist 1, a first powder separator 2, a second powder separator 3, a third powder separator 4, and a bag filter 5. Elevator 7, conveyor 8, bag filter 9, conveyor 10, conveyor 11, ball mill 12, roller press 13 and steady flow bin 14.

[0013] The cement combined grinding system mainly includes two circulation systems. The first circulation system includes the steady flow bin 14, the elevator 1, the roller press 13, the first powder separator 2 and the second powder separator 3. The flow bin 14 enters the roller press 13, and the coarse and fine powder mixture from the roller press 13 is lifted by the hoist 1 and enters the first powder separator 2, and the coarse and fine mixture is dispersed and separated by the first powder separator 2, and the coarse and fine powder mixture is separated by the first powder separator 2. The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com