Cylindrical medium proportioning method for fine grinding of collophanite

A collophosphate and cylindrical technology, applied in the field of ore crushing and grinding, can solve problems such as unreasonable medium ratio, and achieve the effect of reducing overgrinding phenomenon and improving grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Actual measurement of a low-grade collophosite ore σ (uniaxial compressive strength) = 711.61kg / cm 2 , f (Platinum hardness) = 7.12, elastic modulus is 7.22×10 5 kg / cm 2 , is medium-hard to soft ore, Poisson's ratio =0.341, which belongs to the ore with high toughness.

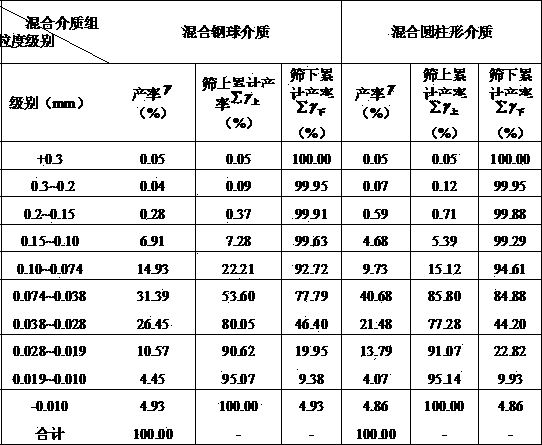

[0021] (2) Screen and analyze the new feed of the ball mill, the specific data is shown in Table 1:

[0022] Level (mm) Yield Cumulative yield on sieve Cumulative yield under sieve +5.0 0.14 0.14 100.00 5.0~2.0 1.51 1.65 99.86 2.0~0.9 6.03 7.68 98.35 0.9~0.45 7.44 15.12 92.32 0.45~0.2 15.55 30.67 84.88 0.2~0.15 22.99 53.66 69.33 0.15~0.10 12.09 65.75 46.34 0.10~0.074 11.28 70.03 34.25 0.074~0.038 12.61 89.64 22.97 0.038~0.028 5.64 95.28 10.36 0.028~0.019 2.03 97.31 4.72 0.019~0.010 0.87 98.18 2.69 -0.010 1.82 100.00 1.82 total .00 - -

[0023] From the above table, we c...

Embodiment 2

[0033] (1) Measured a medium-low grade collophosite ore σ=973.67kg / cm 2 , f=9.74, the modulus of elasticity is 7.18×10 5 kg / cm 2 , is medium-hard to soft ore, Poisson's ratio =0.264, which is a brittle ore.

[0034] (2) Screening and analysis of the new feed to the ball mill, the specific data are as follows:

[0035] Level (mm) Yield Cumulative yield on sieve Cumulative yield under sieve +5.0 3.15 3.15 100.00 5.0~2.0 6.89 10.04 96.85 2.0~0.9 8.37 18.41 89.96 0.9~0.45 7.10 25.48 81.59 0.45~0.2 23.89 49.37 74.52 0.2~0.15 4.95 54.32 50.63 0.15~0.10 17.00 71.32 45.68 0.10~0.074 9.96 81.20 28.68 0.074~0.038 15.44 96.72 18.72 0.038~0.028 1.12 97.84 3.28 0.028~0.019 0.86 98.70 2.16 0.019~0.010 1.03 99.73 1.30 -0.010 0.27 100.00 0.27 total .00 - -

[0036] From the above table, we can see that the ore fed by the ball mill is relatively fine, and the maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com