Tower type grinding flotation machine capable of carrying out grinding while flotation separation

A flotation machine and tower mill technology, applied in flotation, solid separation, etc., can solve the problems of loss of stirring function of flotation machine, no ore grinding, and inability to produce ore grinding, so as to improve the recovery rate of separation , reduce material over-grinding, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

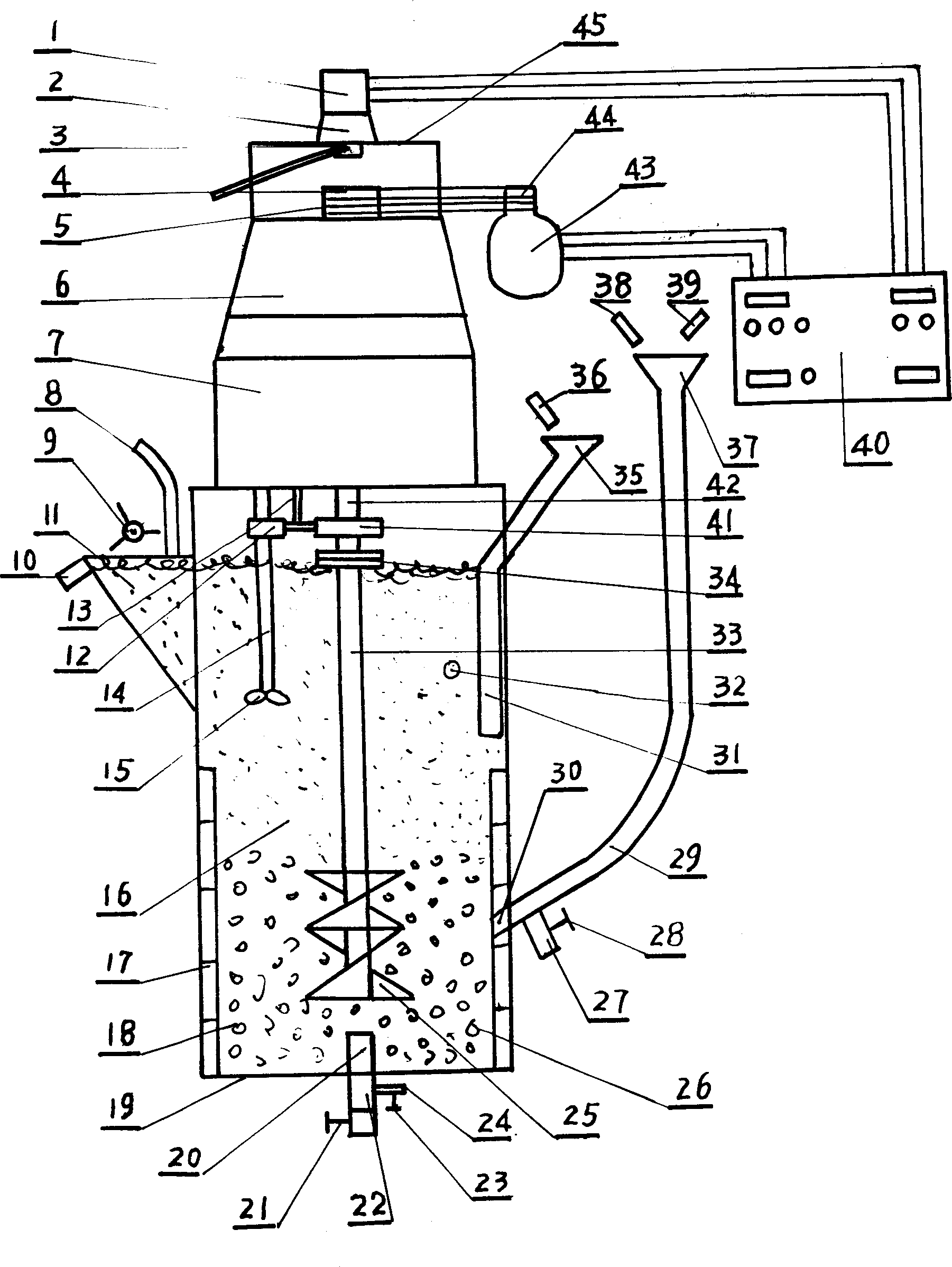

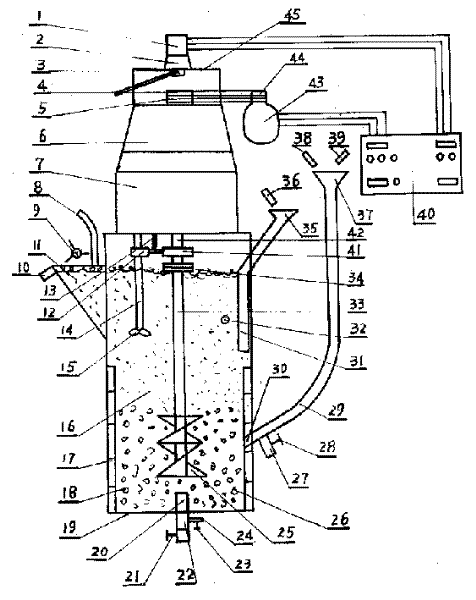

[0011] structured as figure 1 As shown, it consists of auxiliary starter motor 1, auxiliary starter reducer 2, overrunning clutch 3, main drive pulley 4, main drive belt 5, main reducer 6, bearing box 7, concentrate flushing pipe 8, and height-adjustable scraper Device 9, foam overflow tank 10, overflow tank 11, flotation drive passive pulley 12, belt tensioner 13, auxiliary flotation stirring shaft 14, auxiliary flotation stirring impeller 15, flotation chamber 16, without bolts Protective liner 17, (side grinding and floating area) grinding and flotation chamber, that is, vertical grinding chamber 18, machine body 19, aerator 20, pulp valve 21, pulp vent pipe 22, gas filling valve 23, filling valve Gas pipe 24, stirring spiral body 25, ore grinding medium (steel ball) 26, sand return conveying pipe 27, sand return conveying valve 28, sand return pipe 29, sand return port 30, ore feeding guide chute 31, tailings outlet Mine mouth 32, agitating screw shaft 33, connecting flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com