Overflow-discharge-type magnetic hydrocyclone

A hydrocyclone and magnetic technology, applied in the direction of the cyclone device, the device whose axial direction of the cyclone can be reversed, etc., can solve the problems of the adverse effect of the sorting operation, the small effective magnetic field range, and the reduction of the classification efficiency. Low cost, large magnetic field range, and the effect of improving classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

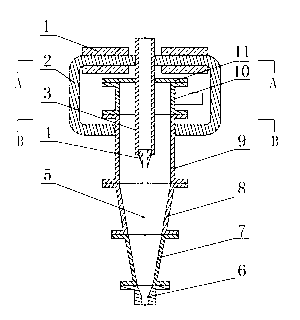

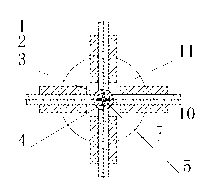

[0026] An overflow discharge type magnetic hydrocyclone. like figure 1 As shown, the overflow discharge type magnetic hydrocyclone includes a common hydrocyclone, four U-shaped iron cores 2 wound with coils 1 and a central magnetic conducting rod 5 .

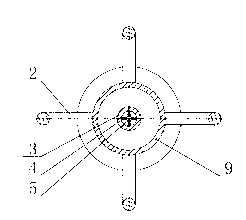

[0027] The ordinary hydrocyclone is composed of a top cover 11, a ore feeding section 10, a cylinder 9, an upper cone 8, a lower cone 7, an overflow pipe 3 and a sand settling nozzle 6. The top cover 11 and the upper end of the ore feeding section 10, the lower end of the ore feeding section 10 and the upper end of the cylinder 9, the lower end of the cylinder 9 and the upper end of the upper cone 8, the lower end of the upper cone 8 and the upper end of the lower cone 7 And the lower end of the lower cone 7 and the shell of the grit chamber 6 are concentrically connected by flanges respectively.

[0028] The overflow pipe 3 is fixedly connected with the central hole of the top cover 11 , and the lower end of the overflow pipe...

Embodiment 2

[0034] An overflow discharge type magnetic hydrocyclone. Except for the following technical parameters, the rest are the same as in Example 1.

[0035] The overflow pipe 3 is fixedly connected with the central hole of the top cover 11 , and the lower end of the overflow pipe 3 is located at the lower part of the cylinder 9 . like figure 1 and Figure 4 As shown, the upper end of the central magnetic conductive rod 5 is concentrically welded to the port at the lower end of the overflow pipe 3 through 2 to 3 connecting fins 4. The lower end of the central magnetic conductive rod 5 is flush with the lower end of the upper cone 8, and the center The diameter of the magnetic conductive rod 5 is 0.25 to 0.30 times the inner diameter of the overflow pipe 3 .

[0036] In this specific embodiment, one end of the four U-shaped iron cores 2 wound with the coil 1 is respectively welded to the outer wall of the upper part of the overflow pipe 3 , and the other ends of the four iron core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com