Coating chamber organic waste gas catalytic combustion treatment system

A technology of catalytic combustion and organic waste gas, which is applied in the field of waste gas treatment system of painting room, can solve the problems of easy blockage of spray paint waste gas and inability of waste gas to reach the standard stably, and achieve the effect of superior thermodynamic performance, significant energy saving effect, and improvement of purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

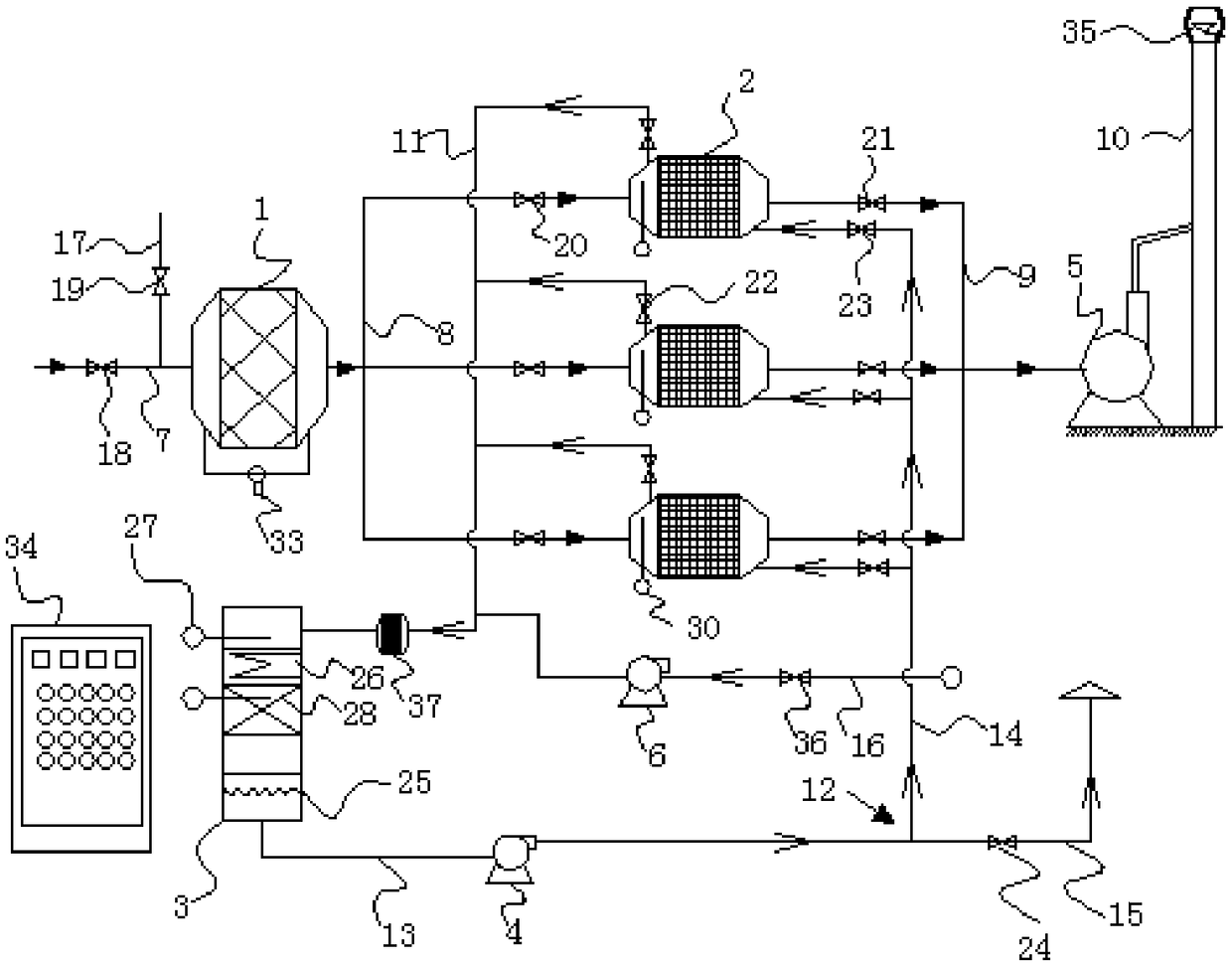

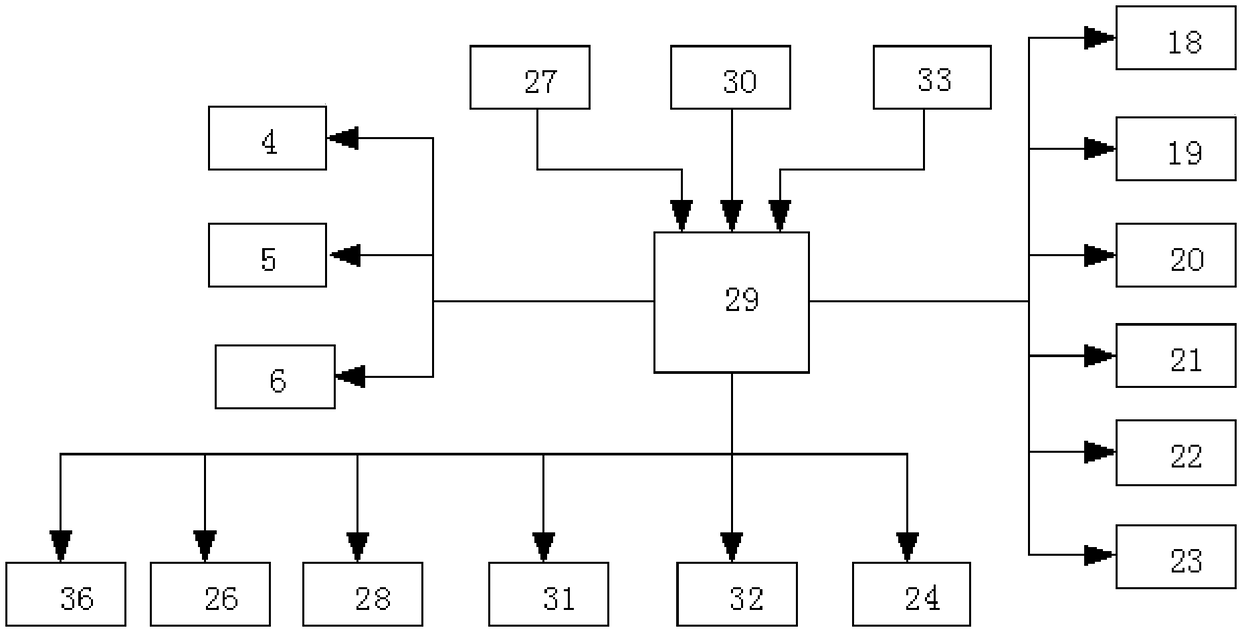

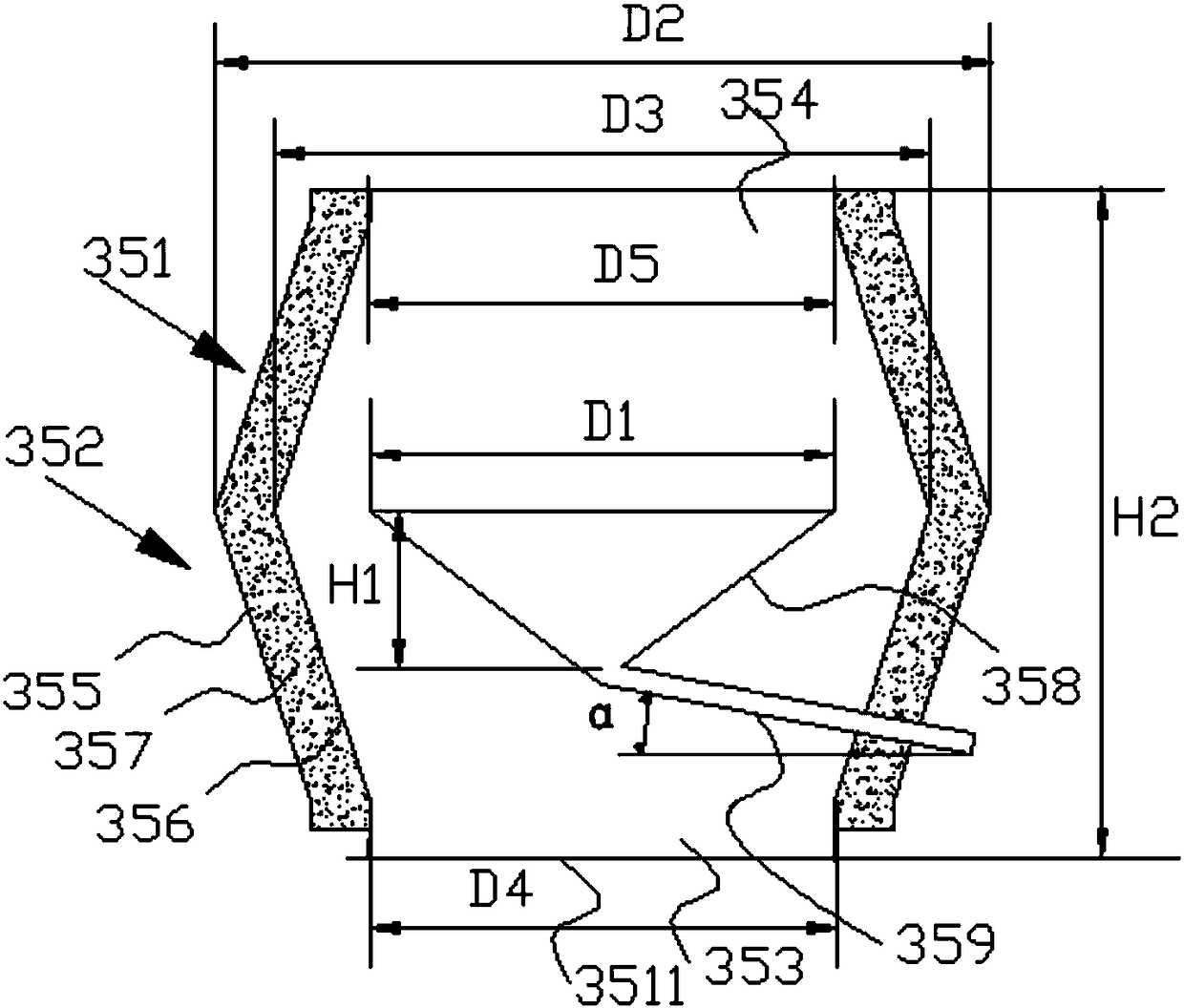

[0043] Example: A catalytic combustion treatment system for organic waste gas in a painting room, such as Figure 1 to Figure 4 As shown, it includes a dry filter 1, an adsorption-desorption box 2, a catalytic combustion device 3, an adsorption fan 5, a desorption fan 4 and an air supply fan 6. The adsorption-desorption box is provided with three, each of the adsorption The desorption boxes all have an adsorption air inlet, an adsorption air outlet, a desorption air inlet and a desorption air outlet, the air inlet of the dry filter is connected to the waste gas collection pipeline 7, and the air outlet of the dry filter is The adsorption air inlet of the adsorption desorption box is connected through the adsorption air intake pipeline 8, the adsorption air outlet of the adsorption desorption box is connected with the adsorption fan through the adsorption air outlet pipeline 9, and the air outlet of the adsorption fan is connected with the exhaust chimney 10 The desorption gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com