Flexible belt body winding station automatic cutting conversion device

An automatic cutting and winding station technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the operator's hand and body injuries, cannot form an automatic winding system, and cannot guarantee accurate operation In order to achieve the effect of high winding conversion efficiency, good positioning accuracy and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First, the implementation modes in the prior art are introduced:

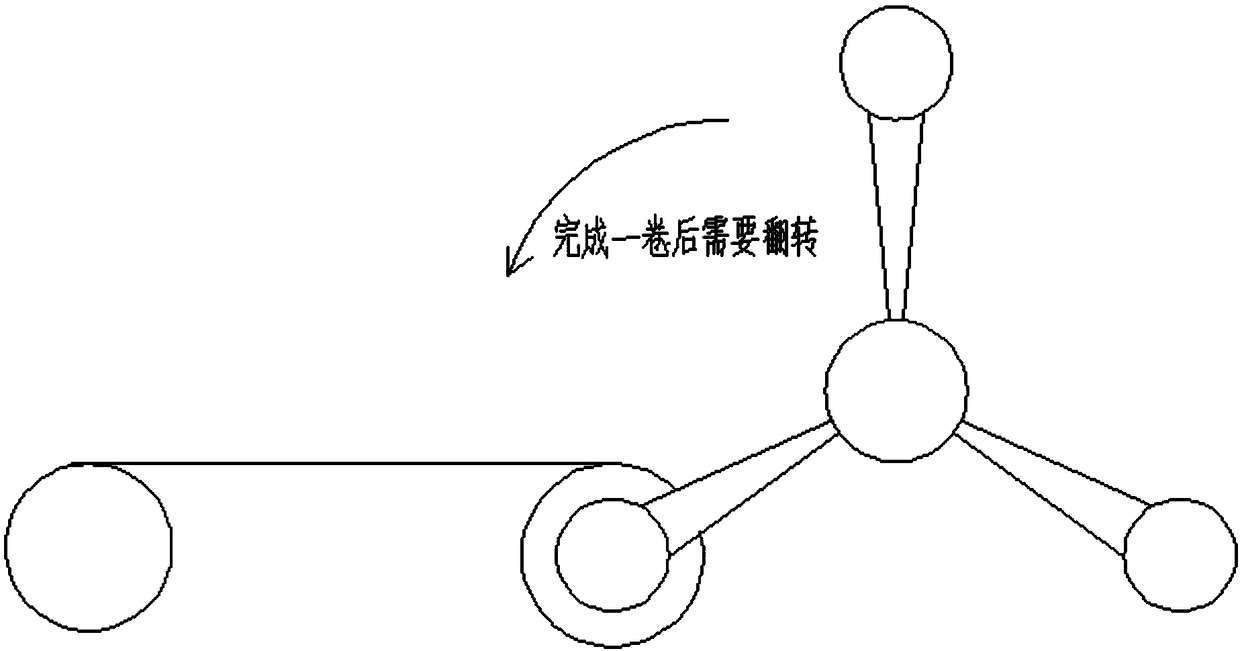

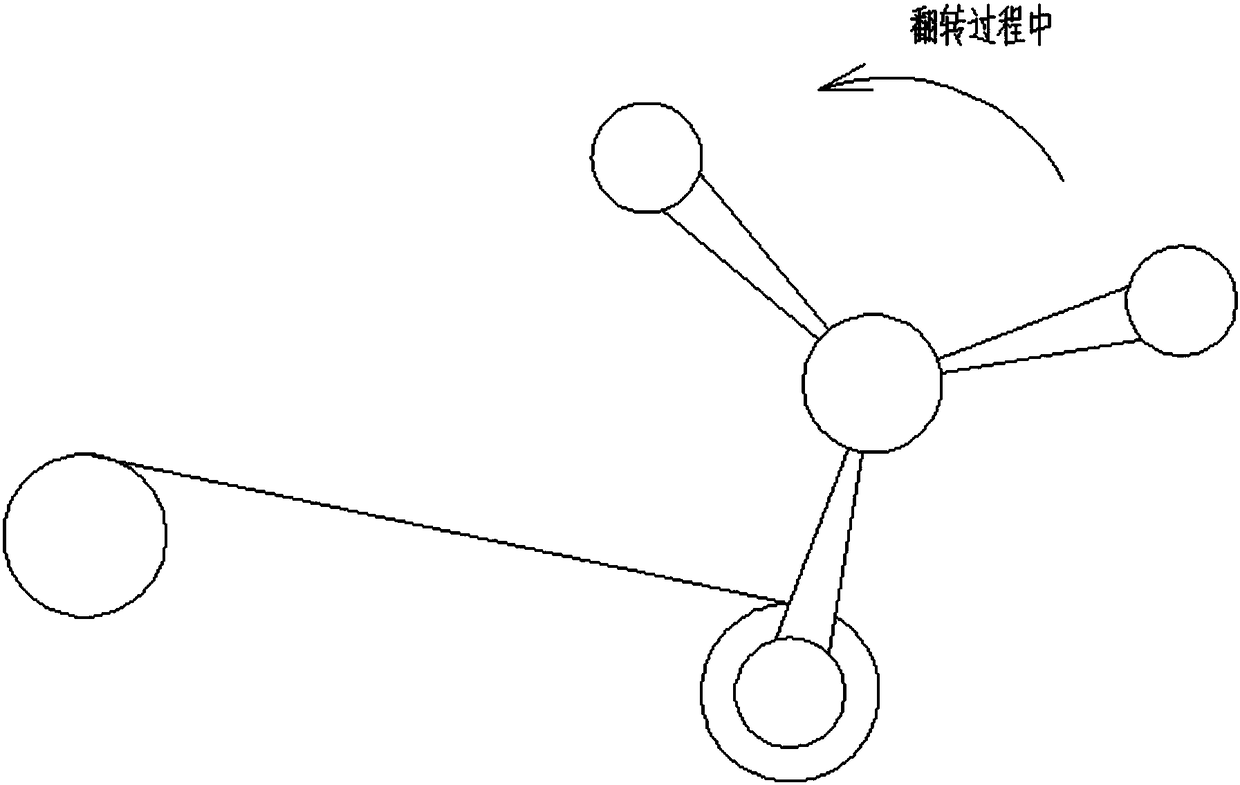

[0035] In the prior art, when the flexible belt is being rolled, when the winding length reaches the set length, the winding station is turned over, such as Figure 1-2 shown.

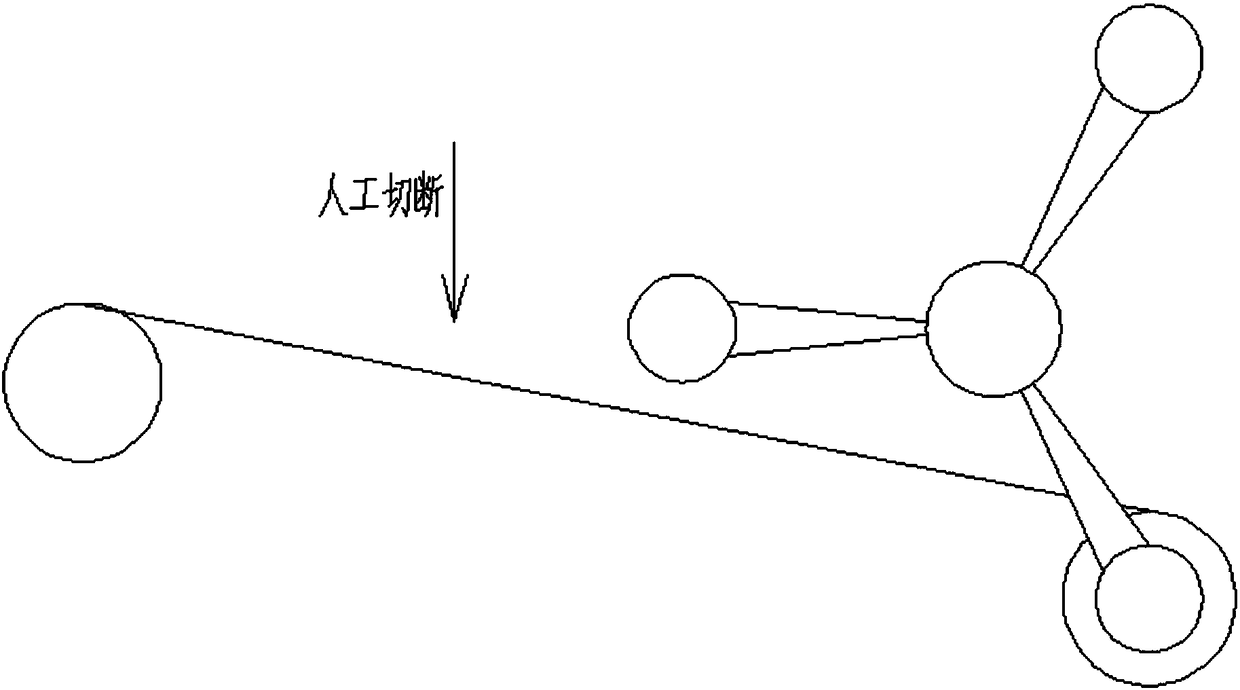

[0036] Such as image 3 As shown in , when the flip is in place, the flexible belt is cut off by manual cutting;

[0037] Such as Figure 4 As shown, the belt body is manually fixed on the roller of the new station, and the winding is carried out, so that the switch of the station is completed.

Embodiment 2

[0039] First introduce the hardware:

[0040] see Figure 5-6 , an automatic cutting conversion device for a flexible belt winding station, comprising a cutting mechanism, a guiding mechanism 4, and a control system; the cutting mechanism is arranged between a flexible belt supply roller and a winding roller group; the guiding mechanism 4 Compress the first part 1 that is not completely separated from the main body of the belt during cutting and the target winding roller, so that the first part 1 is first to be wound on the target winding roller; the first part 1 connected to the first part 1 on the belt is The second part 3 continues to be rewound by the previous rewinding roller until the cutting mechanism completely separates the first part 1 from the second part 3; The cutting action of the mechanism and the rotation transformation of different winding stations of the winding roller group.

[0041] In this example, see figure 2 , the cutting action of the cutting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com