Automatic roll changing device of medical tape automatic winding machine

A tape roll and winding machine technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of inability to adjust the winding speed, high rejection rate, limited degree of automation, etc., to solve the problem of automatic roll change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

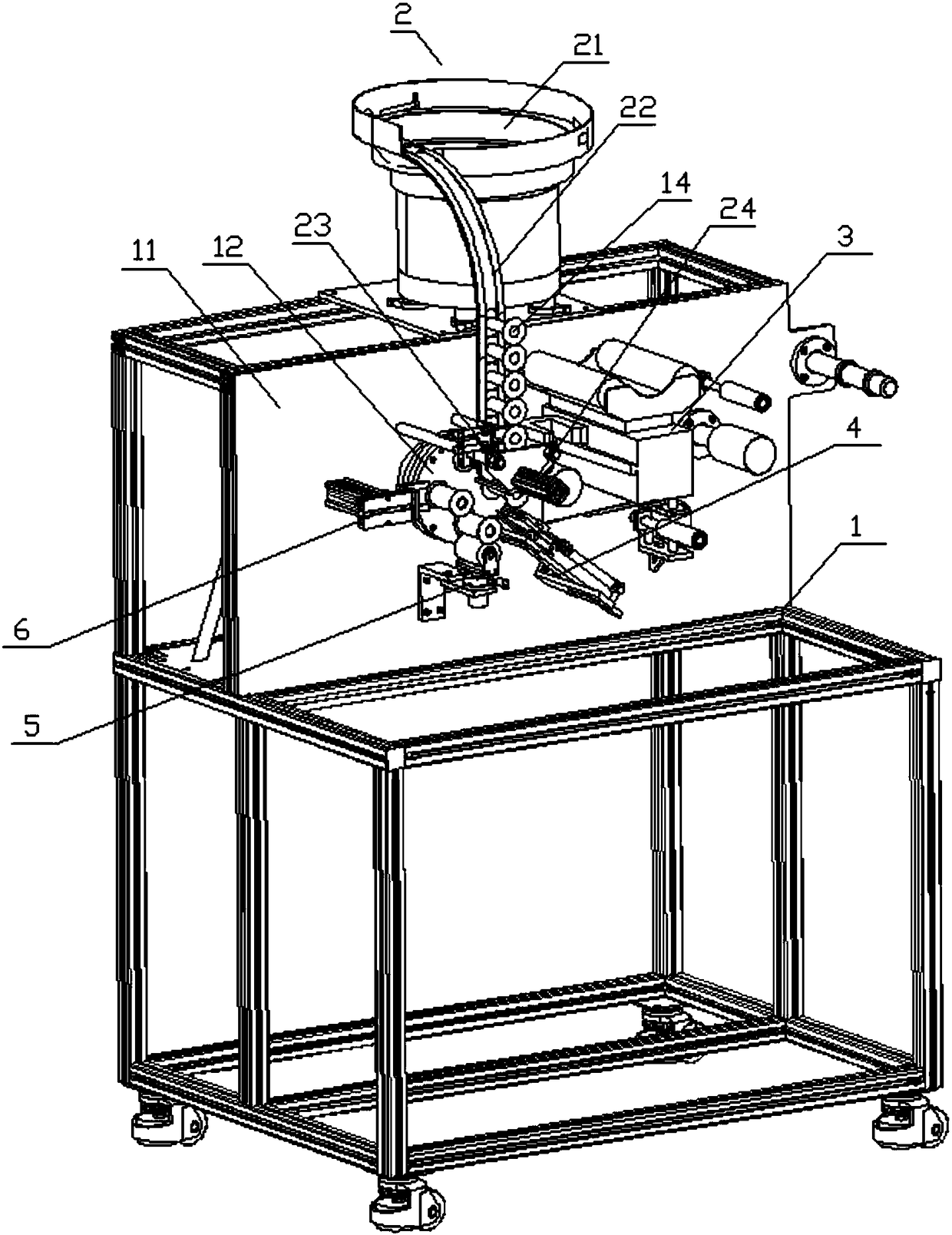

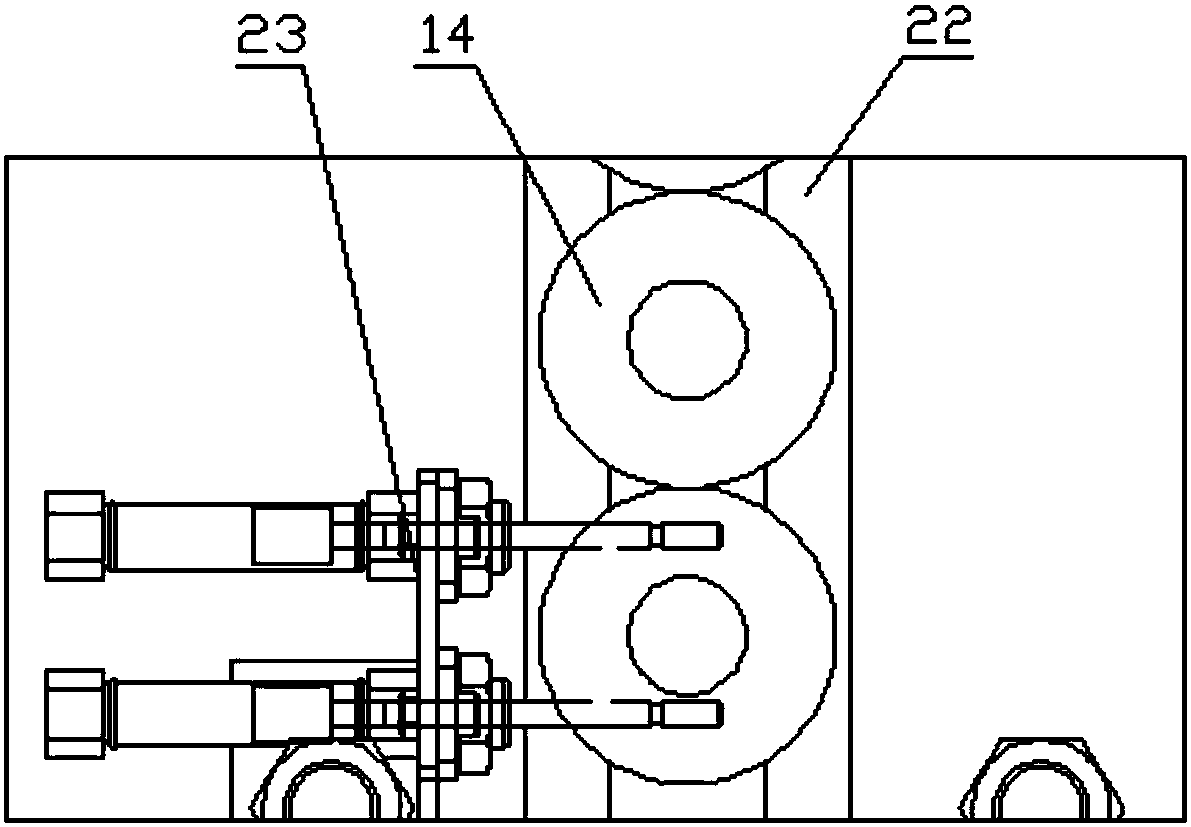

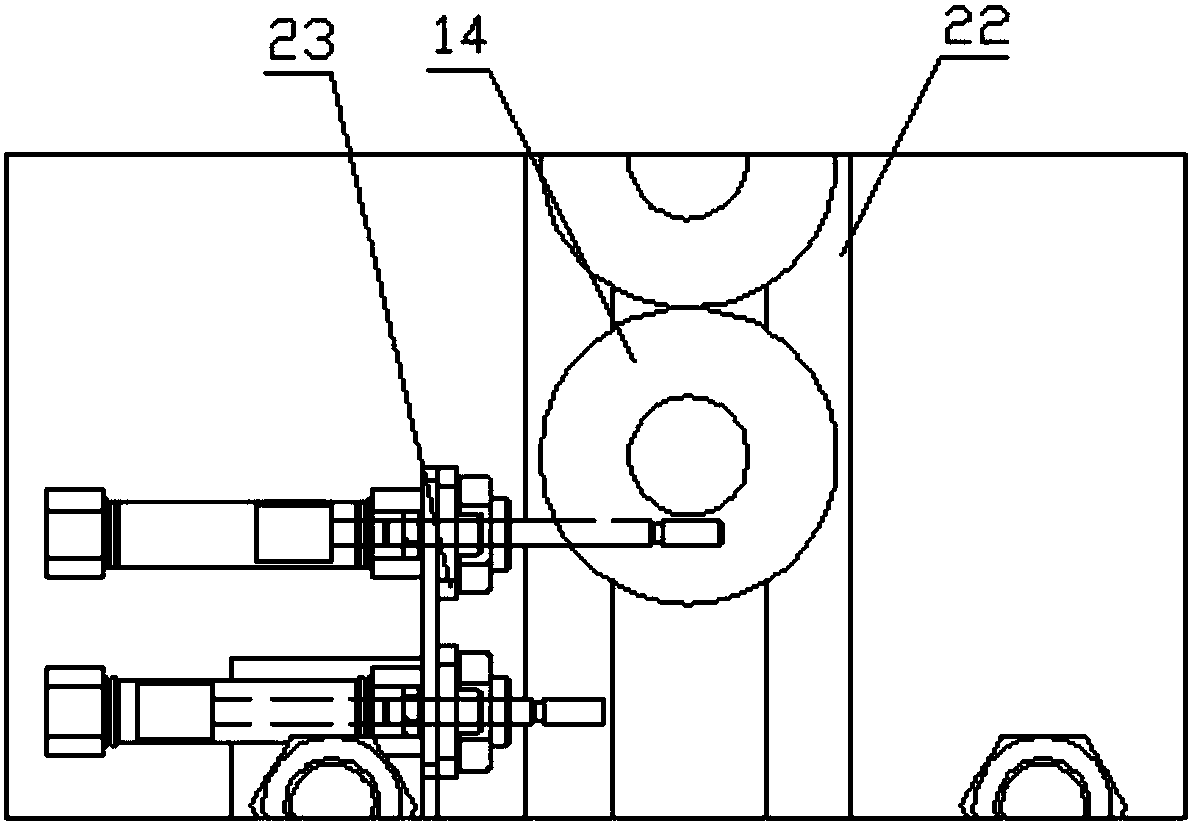

[0026] Such as figure 1 As shown, the medical tape automatic winding machine includes a frame 1 with a working table. The frame 1 includes a profile frame. The bottom four corners of the profile frame are equipped with steering wheels with brakes and steering wheels without brakes to facilitate movement and movement. After positioning, the upper side of the profile frame is provided with a work bench, so that the entire profile frame is L-shaped as a whole, and the work bench 11 is arranged on the inner side of the work bench and is vertically arranged. A four-station turntable 12 is provided on the work surface 11, and the four-station turntable 12 is evenly provided with automatic feeding stations, automatic winding stations, automatic roll changing stations, and automatic unloading stations along the circumferential direction. , A stepping motor is arranged on the inner side of the workbench. The stepping motor drives the main shaft to rotate through a belt transmission belt,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com