Rapid on-line detecting method and system for wood material strength

A wood material and strength technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve the problems of human error, time-consuming, high operator requirements, and improve pertinence and accuracy, positioning and hitting Accurate and improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

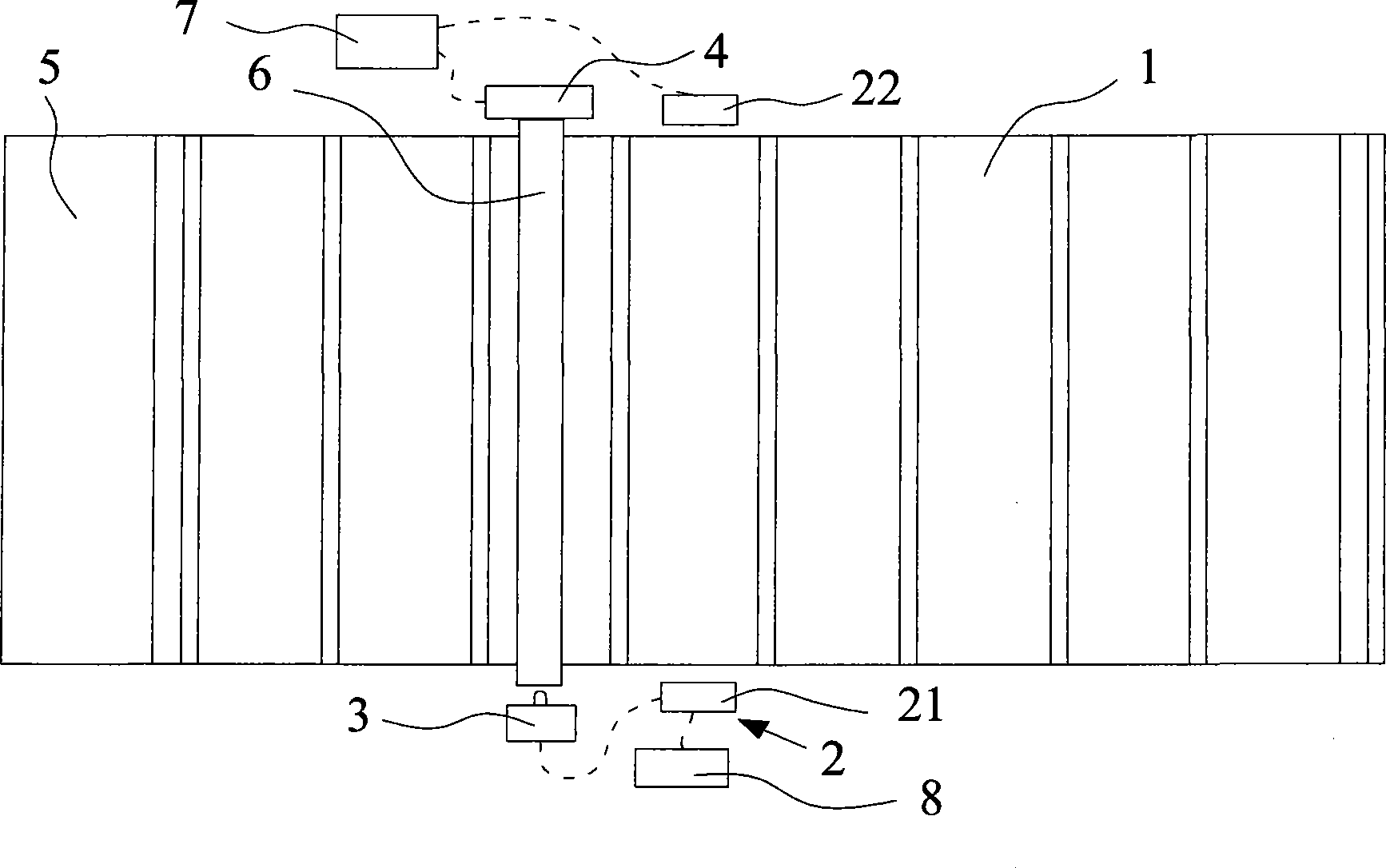

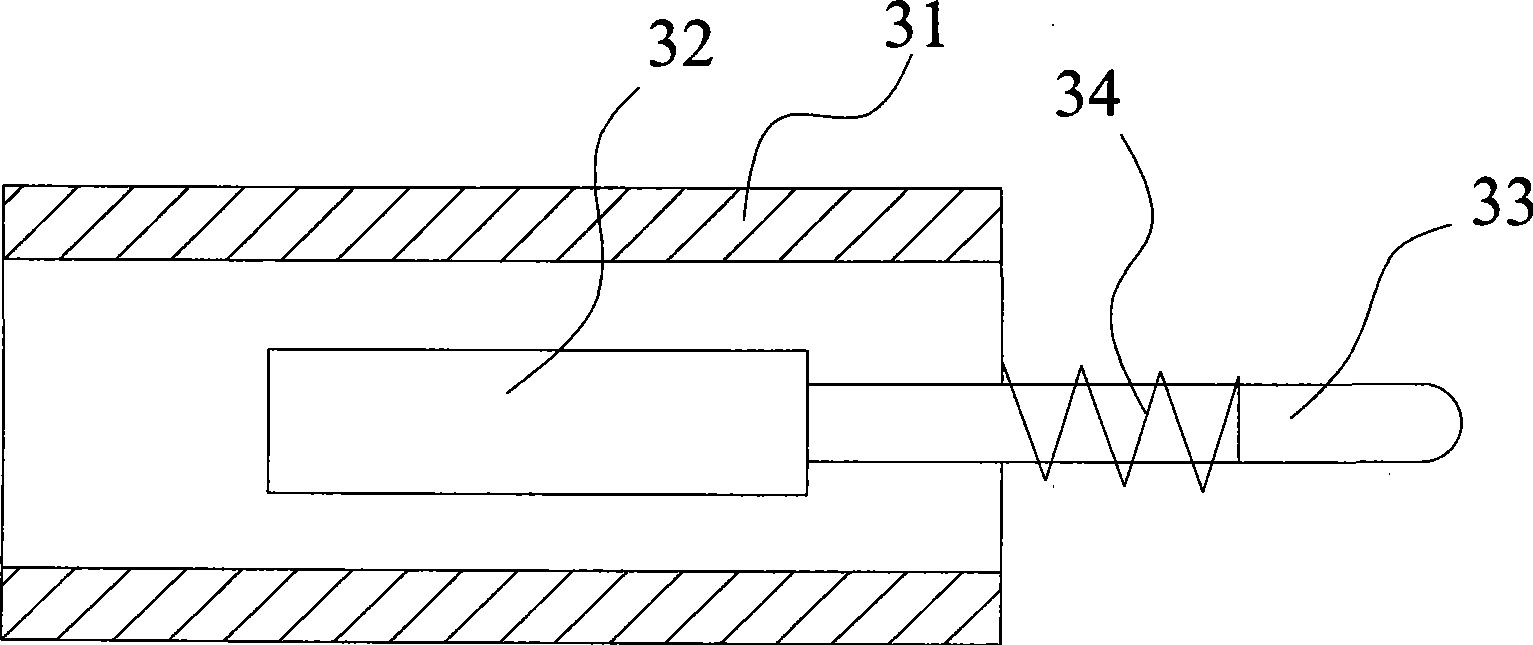

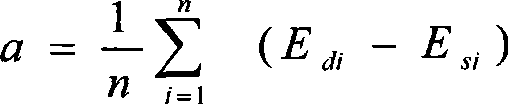

[0040] Such as figure 1 As shown, the present invention includes: a transmission mechanism 1 , a laser sensor 2 , a striker 3 , a signal pickup 4 , a computer 7 and a weighing device 5 . The conveying mechanism 1 is used for conveying the object 6 to be inspected. The laser sensor 2 is arranged on one side of the conveying mechanism 1, and is used to detect the position of the inspected object 6 online, and determine the center hitting time according to the conveying speed and the cross-sectional size of the inspected object 6; the striker 3 is arranged on the conveying mechanism One side of 1 is used to strike the central area of the end of the object 6 according to the striking time instruction of the laser sensor 2; the signal pickup 4 is arranged on the other side of the transmission mechanism 1 opposite to the striker 3, Used to receive the mechanical wave frequency signal generated on the inspected object 6; the weighing device 5 is used to detect the quality of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com