High-dielectric-constant silicon rubber and preparation method thereof

A technology with high dielectric constant and giant dielectric constant, which is applied in the field of high dielectric constant silicone rubber and its preparation, can solve the problems of large potential distribution drop, etc., to ease the concentration of electric field intensity, optimize electric field distribution, and reduce operation failures The effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

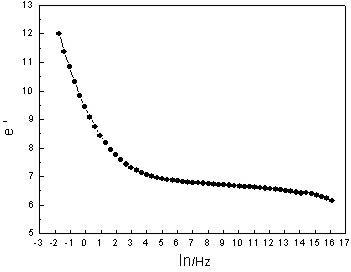

[0041] Take 4.4kg of methyl vinyl silicone rubber and 0.6kg of fumed silica as a reinforcing filler. Add in three times during the rubber mixing process. During the rubber mixing process, add ceramic powder CCTO in three equal parts for a total of 7.50kg. At the same time, add 100 mL of alkoxy crosslinking agent, 50 mL of vinyl liquid silicone rubber, and 50 mL of hydroxyl silicone oil. After mixing uniformly in an internal mixer at 60° C., vacuum kneading was carried out for 45 minutes to obtain a silicone rubber composite material. The dielectric properties of the vulcanized product (the vulcanizing agent is DCP, the added mass is 50g, the same as in the following examples) are tested, and the real dielectric constant at 50Hz is 7.06. figure 1 It can be seen that the silicon rubber material of this embodiment can optimize the distribution of the electric field and alleviate the concentration of the electric field intensity at the high-voltage part, as shown in the spectrum o...

Embodiment 2

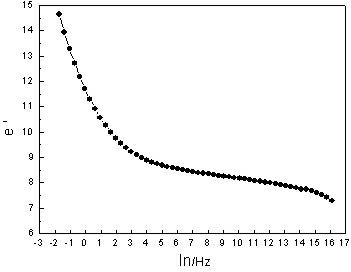

[0043] Take 4.4kg of methyl vinyl silicone rubber, 0.6kg of fumed silica as a reinforcing filler, add in three times during the rubber mixing process, add ceramic powder CCTO in batches during the rubber mixing process, a total of 8.57kg, and 0.71kg of conductive carbon black, While adding the powder, add 100mL of alkoxy crosslinking agent, 50mL of vinyl liquid silicone rubber, and 50mL of hydroxyl silicone oil. After mixing uniformly in an internal mixer at 60° C., vacuum kneading was carried out for 45 minutes to obtain a silicone rubber composite material. The dielectric properties of the vulcanized product were tested, and the real dielectric constant at 50 Hz was 8.89. figure 2 In fact, the variation spectrum of permittivity with frequency.

Embodiment 3

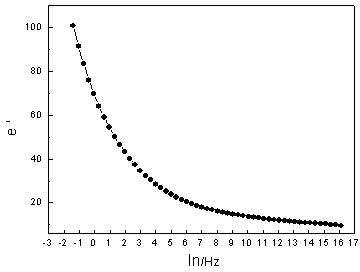

[0045] Take 4.4kg of methyl vinyl silicone rubber, 0.6kg of fumed silica as a reinforcing filler, and add it in three times during the rubber mixing process. During the rubber mixing process, add ceramic powder CCTO in batches totaling 9.68kg, conductive carbon black 1.45kg, While adding the powder, add 150mL of alkoxy crosslinking agent, 50mL of vinyl liquid silicone rubber, and 50mL of hydroxyl silicone oil. After mixing uniformly in an internal mixer at 60° C., vacuum kneading was carried out for 45 minutes to obtain a silicone rubber composite material. The dielectric properties of the vulcanized product were tested, and the real dielectric constant at 50 Hz was 28.50. image 3 In fact, the variation spectrum of permittivity with frequency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com