Composite wave-absorbing material and preparation method thereof

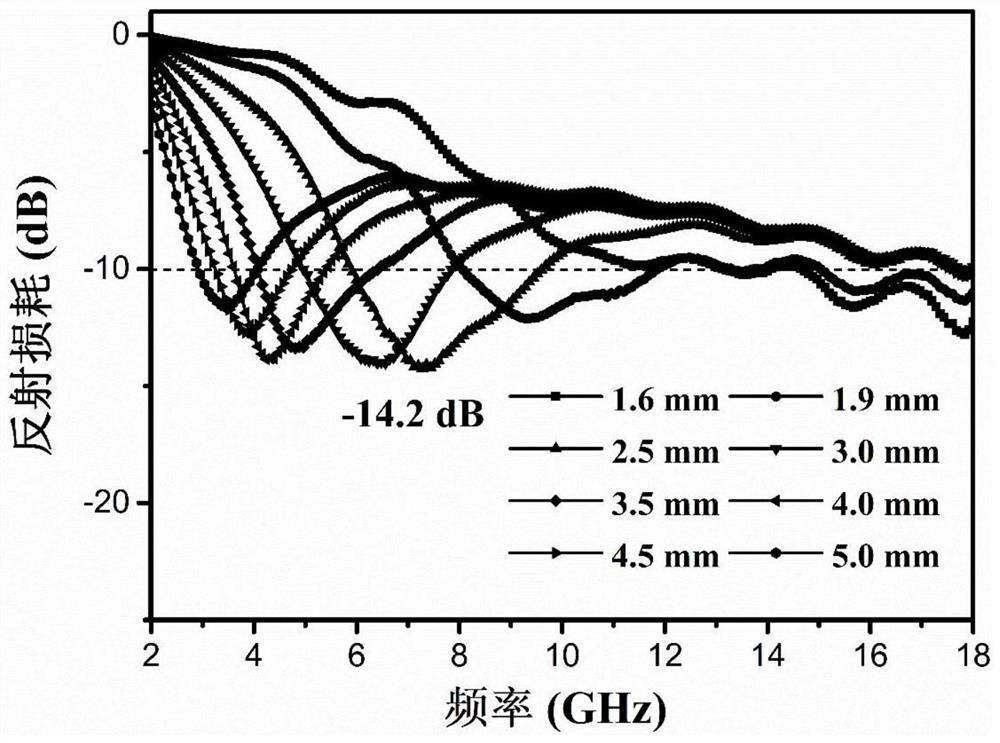

A composite microwave absorbing material and composite material technology are applied in the field of preparation of ternary multi-loss matching synergistic composite microwave absorbing materials, which can solve the problems of high density of composite materials, poor impedance matching characteristics, and poor absorption performance, and achieve strong Dielectric effect, improved impedance matching, reduced density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

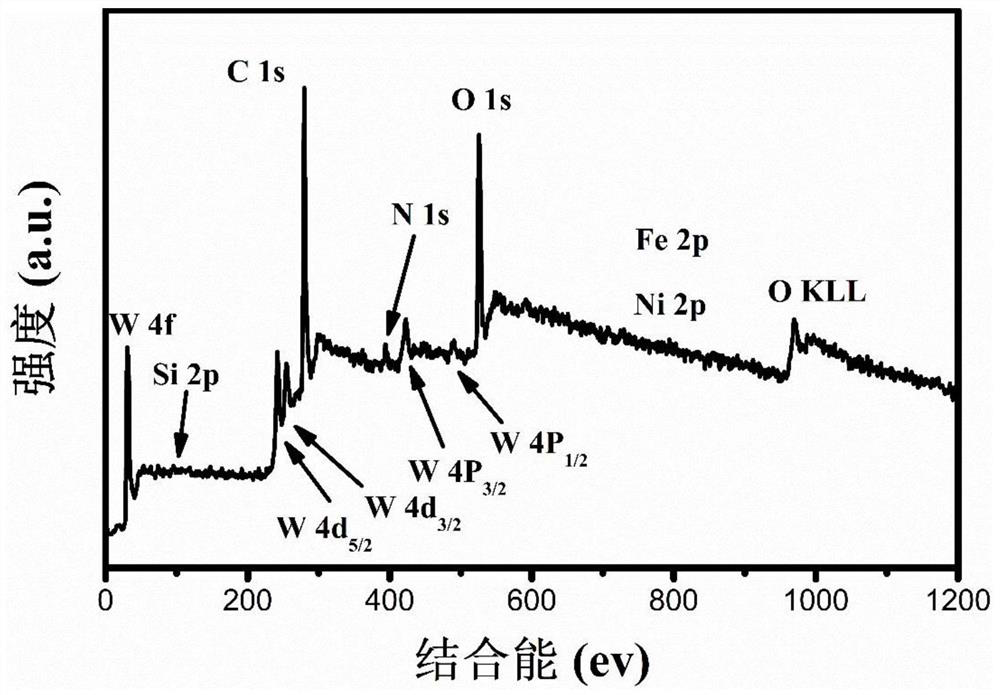

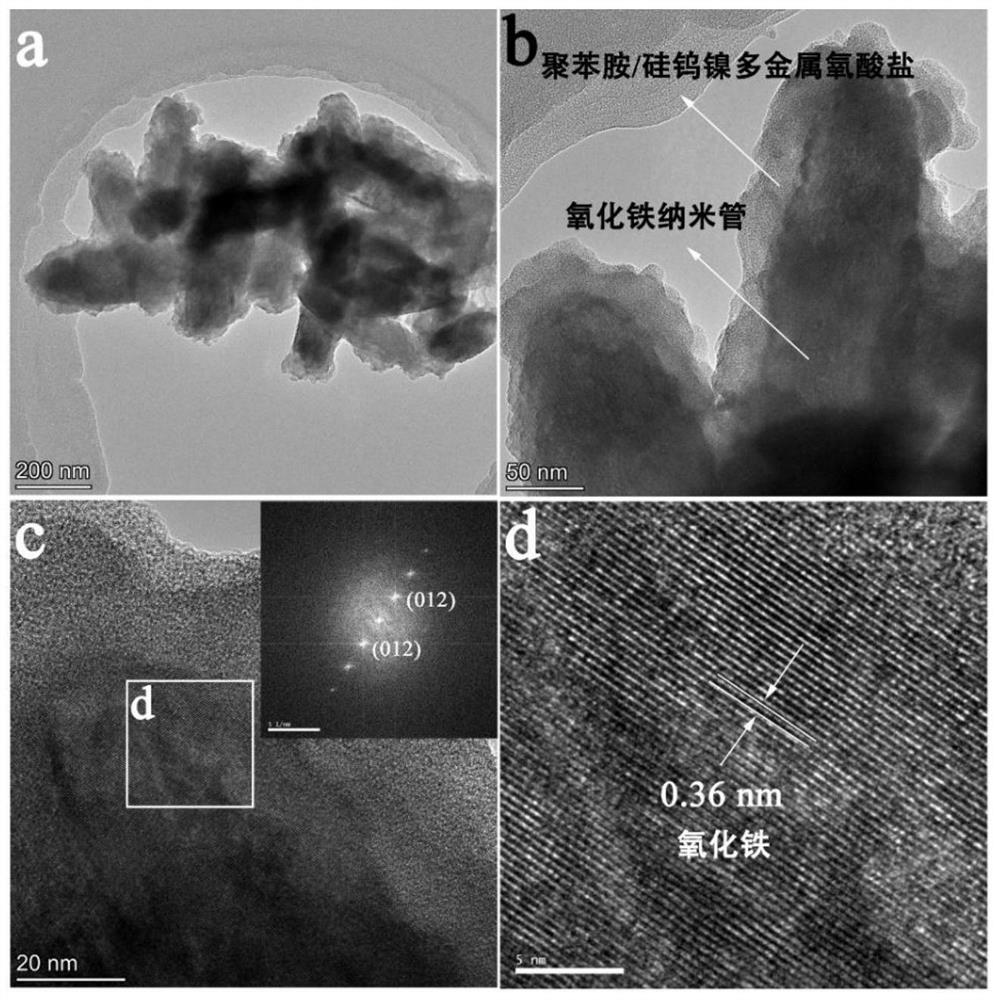

[0023] 1. According to m 硫酸钠 :m 二水磷酸二氢钠 :m 六水三氯化铁 :m 去离子水 =1:1.11:68:11900, dissolve sodium sulfate, sodium dihydrogen phosphate dihydrate and ferric chloride hexahydrate in deionized water, stir ultrasonically for 30 minutes at room temperature, react at 200°C for 24 hours, and collect by magnetic washing As a result, iron oxide nanotubes were obtained.

[0024] 2. According to m 硅钨多金属氧酸盐 :m 六水硫酸镍 :m 去离子水 :m 氯化钾 =1:0.084:4.59:0.29, dissolve silicotungsten polyoxometalate and nickel sulfate hexahydrate in deionized water, react in a water bath at a constant temperature of 40°C for 15 minutes, then add potassium chloride, place in the refrigerator for 24 hours to crystallize, add water to weigh Crystallization to obtain silicon tungsten nickel polyoxometalate.

[0025] 3. According to m 氧化铁纳米管 :m 硅钨镍多金属氧酸盐 :m 1M盐酸 :m 苯胺 =1:3.8:356:0.99, the iron oxide nanotubes obtained in step (1) and the silicon-tungsten-nickel polyoxometalates obtained in step (2) are added to 1M...

Embodiment 2

[0030] 1. According to m 硫酸钠 :m 二水磷酸二氢钠 :m 六水三氯化铁 :m 去离子水 =1:1.14:68.7:11905, dissolve sodium sulfate, sodium dihydrogen phosphate dihydrate and ferric chloride hexahydrate in deionized water, stir ultrasonically at room temperature for 30 minutes, react at 200°C for 24 hours, and collect by magnetic washing As a result, iron oxide nanotubes were obtained.

[0031] 2. According to m 硅钨多金属氧酸盐 :m 六水硫酸镍 :m 去离子水 :m 氯化钾 =1:0.082:4.69:0.31, dissolve silicotungsten polyoxometalate and nickel sulfate hexahydrate in deionized water, react in a water bath at a constant temperature of 40°C for 15min, then add potassium chloride, place in the refrigerator for 24h to crystallize, add water to Crystallization to obtain silicon tungsten nickel polyoxometalate.

[0032] 3. According to m 氧化铁纳米管 :m 硅钨镍多金属氧酸盐 :m 1M盐酸 :m 苯胺 =1:3.75:355:1.02, adding the iron oxide nanotubes obtained in the step (1) and the silicon-tungsten-nickel polyoxometalates obtained in the step (2) to 1M hydrochlo...

Embodiment 3

[0036] 1. According to m 硫酸钠 :m 二水磷酸二氢钠 :m 六水三氯化铁 :m 去离子水 =1:1.19:69.2:12000, dissolve sodium sulfate, sodium dihydrogen phosphate dihydrate and ferric chloride hexahydrate in deionized water, stir ultrasonically for 30 minutes at room temperature, react at 200°C for 24 hours, and collect by magnetic washing As a result, iron oxide nanotubes were obtained.

[0037] 2. According to m 硅钨多金属氧酸盐 :m 六水硫酸镍 :m 去离子水 :m 氯化钾 =1:0.08:4.8:0.32, dissolve silicotungsten polyoxometalate and nickel sulfate hexahydrate in deionized water, react in a water bath at a constant temperature of 40°C for 15 minutes, then add potassium chloride, place in the refrigerator for 24 hours to crystallize, add water to weigh Crystallization to obtain silicon tungsten nickel polyoxometalate.

[0038] 3. According to m 氧化铁纳米管 :m 硅钨镍多金属氧酸盐 :m 1M盐酸 :m 苯胺 =1:3.68:353:1.03, adding the iron oxide nanotubes obtained in step (1) and the silicon-tungsten-nickel polyoxometalates obtained in step (2) to 1M h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com