Organic waste gas treatment device

A treatment device, a technology for organic waste gas, applied in the direction of combustion methods, lighting and heating equipment, tubular elements, etc., can solve the problem of insufficient heat recovery efficiency of regenerative combustion equipment, decreased ability of heat storage materials to absorb heat energy, and gas flow cycle To avoid problems such as property fluctuations, to achieve the effect of compact structure, stable oxidation area and stable gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

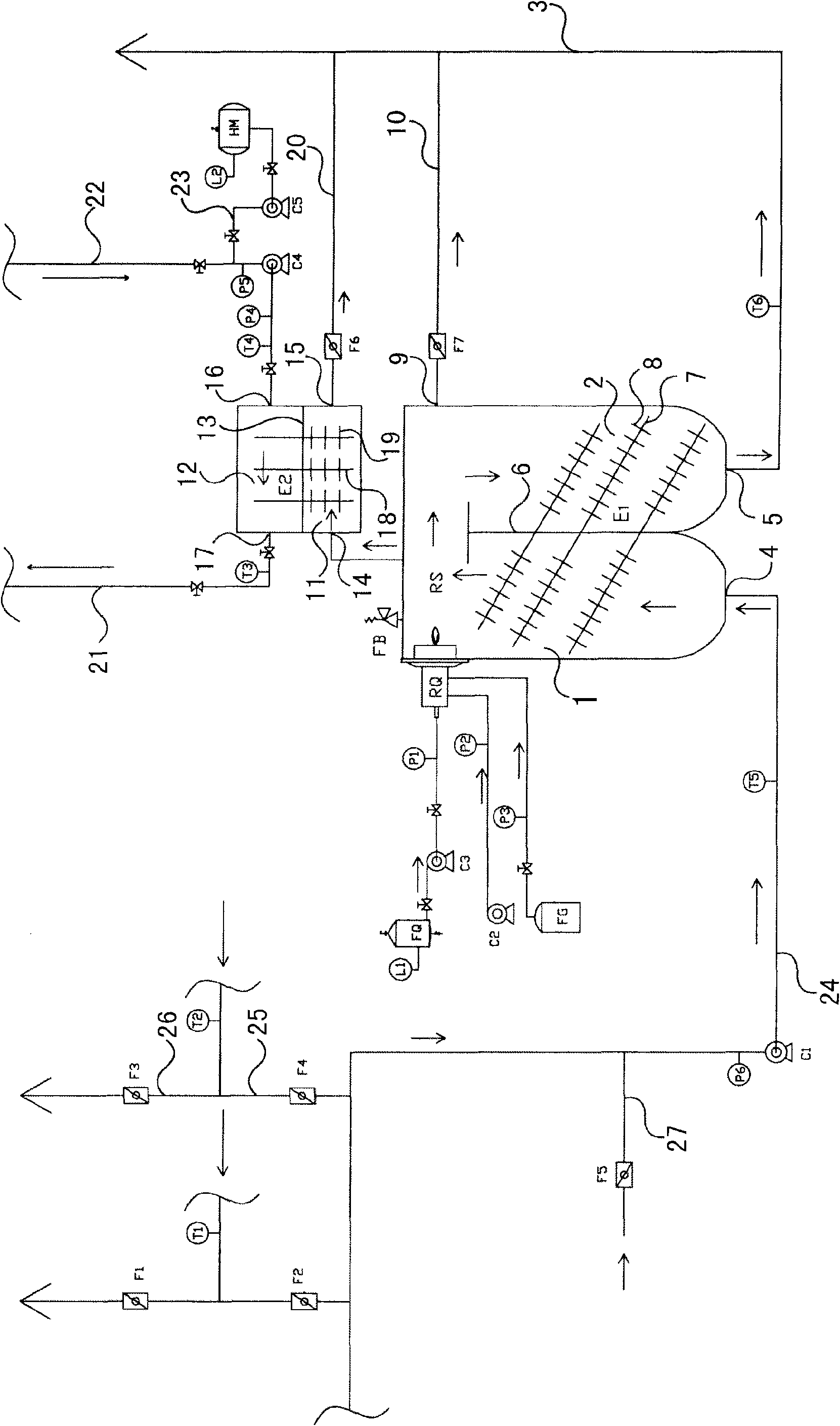

[0019] Such as figure 1 As shown, this organic waste gas treatment device includes an organic waste gas inlet pipe, a preheating chamber 1, a combustion chamber RS, a heat recovery chamber 2, an exhaust pipe 3, a heat pipe heat exchanger E1, and a heat transfer oil heat recovery device. Burner RQ is installed.

[0020] The preheating chamber 1, the combustion chamber RS and the heat recovery chamber 2 are connected sequentially. The preheating chamber 1 is provided with a gas inlet 4, and the heat recovery chamber 2 is provided with a gas outlet 5. The organic waste gas enters the pipeline and is connected with the gas inlet 4. The gas pipeline 3 is connected with the gas outlet 5 . In this embodiment, the preheating chamber 1 and the heat recovery chamber 2 are arranged side by side, and a partition 6 is arranged between the preheating chamber 1 and the heat recovery chamber 2; the combustion chamber RS is above the preheating chamber 1 and the heat recovery chamber 2, ...

Embodiment 2

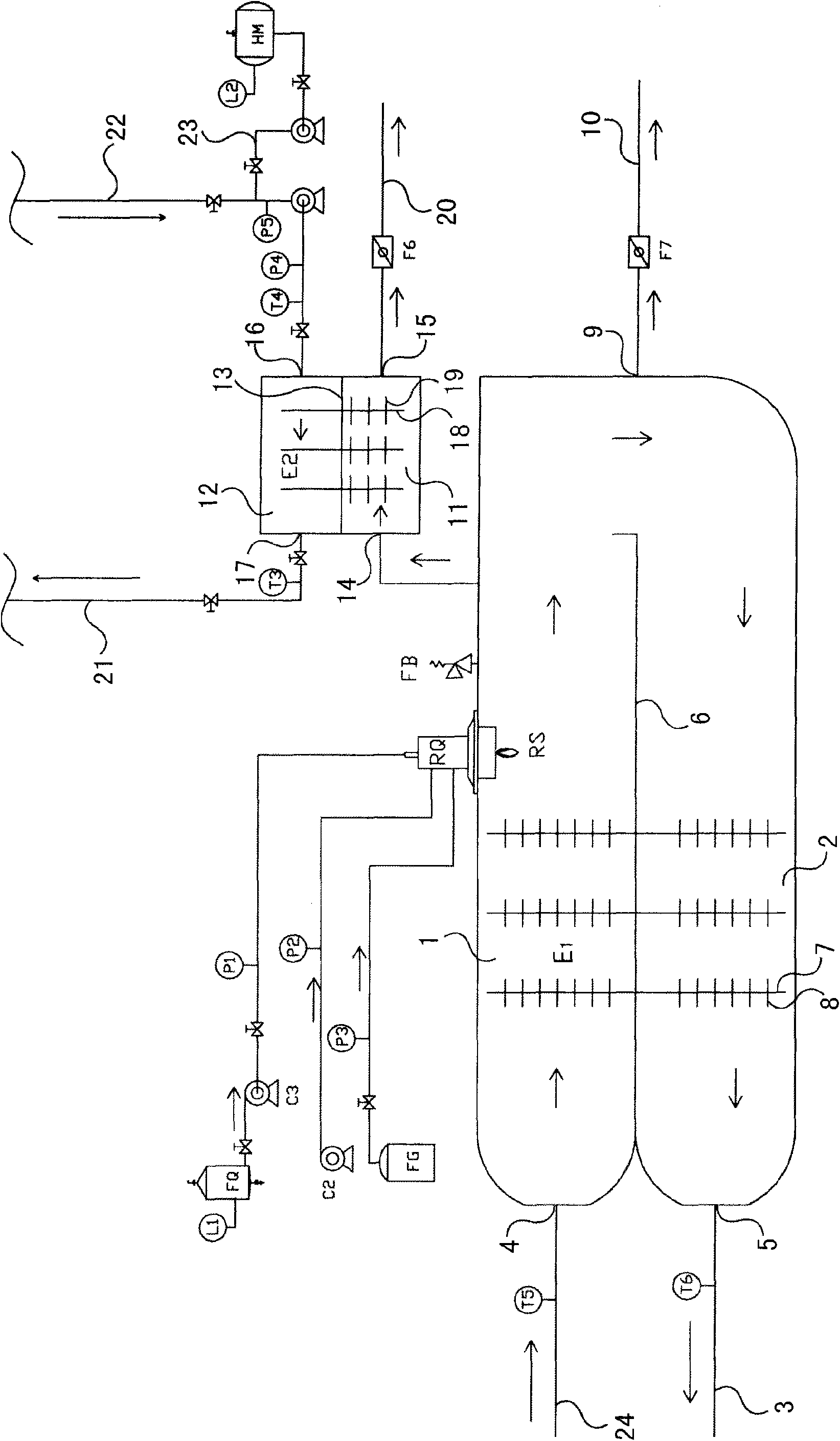

[0053] Such as figure 2 , in this organic waste gas treatment device, the preheating chamber 1 is arranged above the heat recovery chamber 2, and a partition 6 is arranged between the preheating chamber 1 and the heat recovery chamber 2, and the partition 6 is arranged along the horizontal direction, and the combustion chamber RS It is on the right side of the preheating chamber 1; the heat pipe 7 is installed on the partition 6, and the heat pipe 7 and the partition 6 are perpendicular to each other; in the heat recovery chamber 2, the heat pipe 7 is along the flow direction of the high-temperature gas generated after combustion (that is, from Right to left) are arranged step by step, correspondingly, in the preheating chamber 1, the heat pipes 7 are arranged step by step along the flow direction of the organic waste gas (that is, from left to right). The rest of the structure and working principle of the organic waste gas treatment device are the same as those in Embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com