Steel band cleaning device

A technology for cleaning devices and steel strips, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as replacement, increased use costs, and impact on production efficiency, and achieve equipment failure rates Low, high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

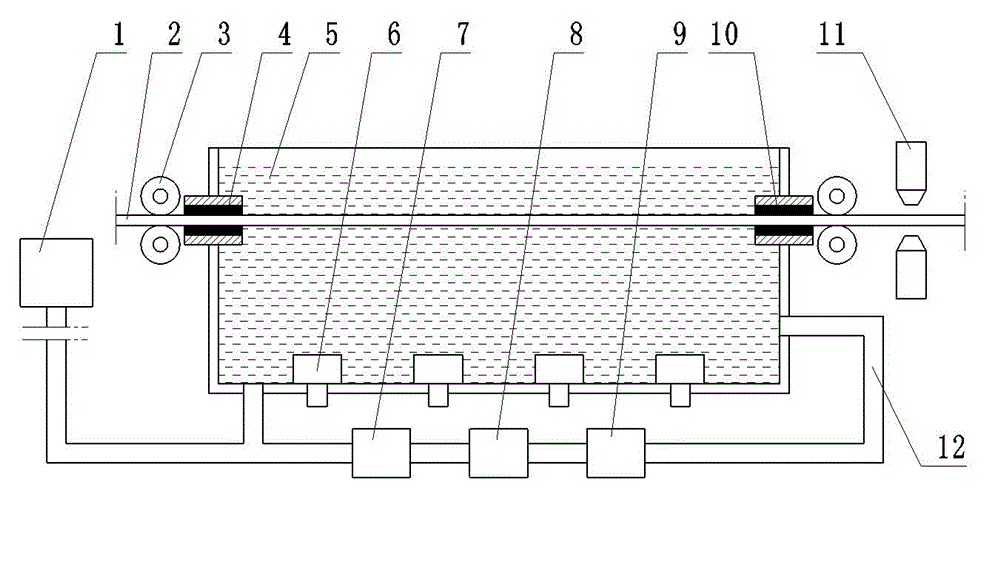

[0017] Embodiment 1: with reference to attached figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, including a replenishing water tank 1, a cleaning water tank (5), a steel belt conveying mechanism (3), a circulating water pipeline (12), a circulating water filter (7), and a circulating water pump (8) and the heater (9), the cleaning water tank (5) is provided with a steel strip inlet (4) and a steel strip outlet (10), and 4 ultrasonic generators are arranged side by side at the lower part of the steel strip 1 traveling route in the cleaning water tank (5) Device (6), is provided with drier (11) behind the steel belt outlet (10) of cleaning water tank (5), and this drier 11 is a hot-air type drier.

Embodiment 2

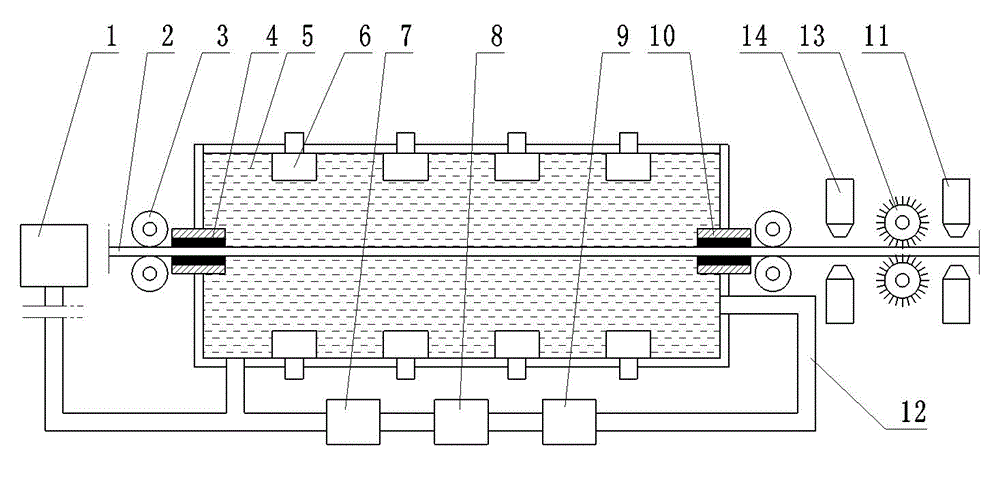

[0018] Embodiment 2: with reference to attached figure 2 , is a schematic diagram of the structure of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that there is a shower (14) and a roller brush 13 before the dryer (11). The steel strip 2 after the ultrasonic treatment is sprayed and rinsed, and the surface water is brushed off by the roller brush 13, and then dried.

Embodiment 3

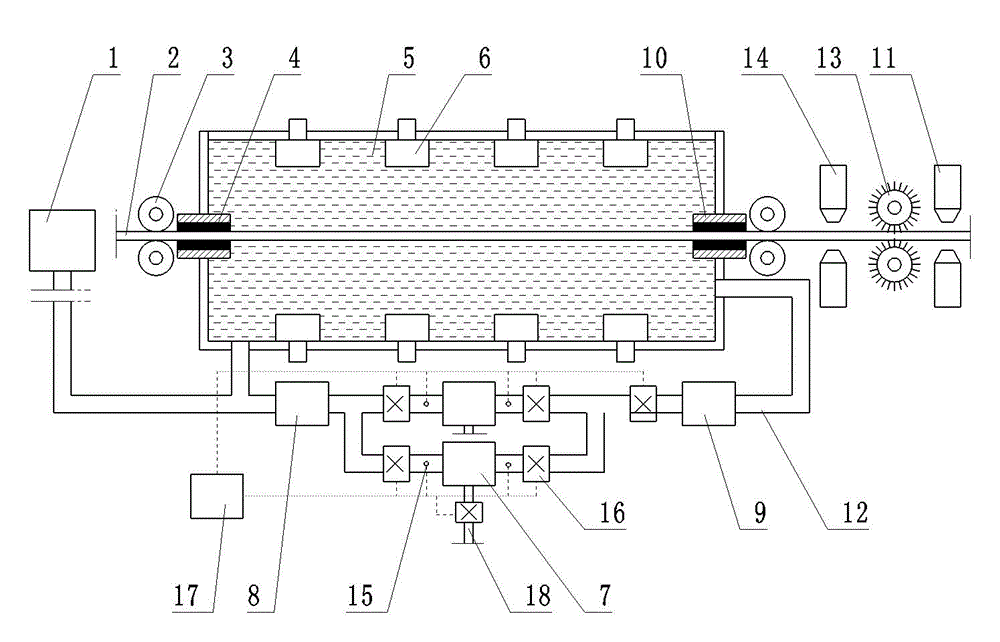

[0019] Embodiment 3: with reference to attached Figure 3-4 , is a schematic structural diagram of Embodiment 3 of the present invention. Compared with Embodiment 2, the difference of this embodiment is that four ultrasonic generators are arranged side by side on the upper and lower parts of the plane where the steel strip 1 travels in the cleaning water tank (5). Two sets of screen type circulating water filters (7) are connected in parallel in the circulating water pipeline (12), and the circulating water pump (8) is set at the front of the two sets of circulating water filters (7). Group circulating water filter (7) is equipped with filter housing (7-4), filter screen 7-1, water inlet (7-3), water outlet (7-2) and backwash pipe (18) , the water inlet end (7-3), the water outlet end (7-2), the backwash pipe (18) and the circulating water pipeline (12) are all equipped with valves (16), and the above circulating water filter ( 7) An automatic control device (17) is provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com