Automatic conveyor line for potted plant parameter measurement

A technology of automatic conveying and parameter measurement, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve problems such as staying in the laboratory stage, and achieve the effects of improving measurement efficiency, reducing labor intensity, and low operating failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

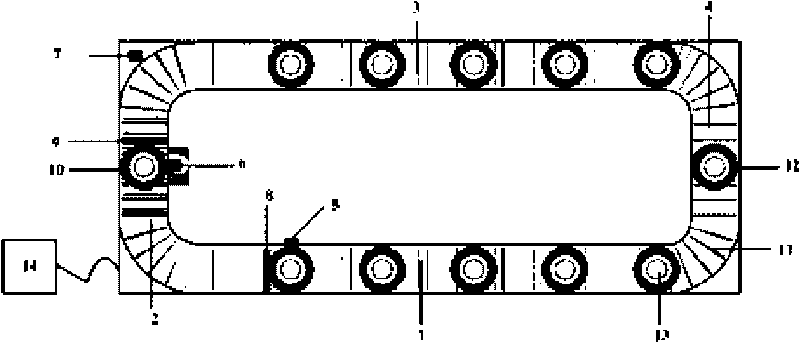

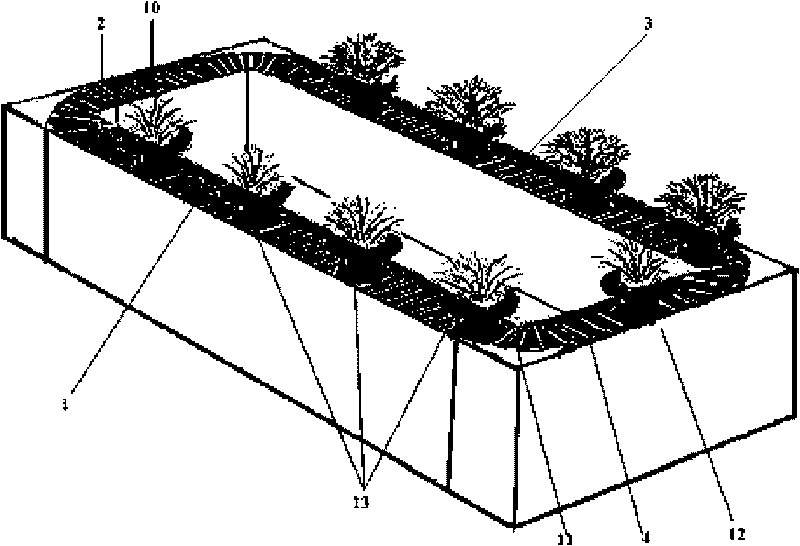

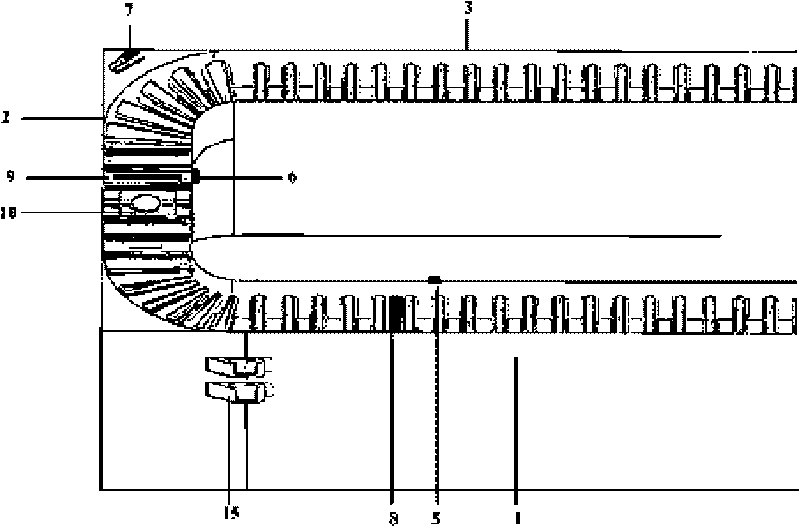

[0017] Combine figure 1 , figure 2 , image 3 As shown, the present invention mainly includes four power stainless steel roller transmission lines, the first photoelectric switch 5 and the first lifting plate 8 are on the first conveyor line 1, the second photoelectric switch 6, the third photoelectric switch 7 and the second lifting plate 9 are all on the second conveying line 2. The actions of the first lifting plate, the second lifting plate, the first conveying line 1, the second conveying line 2, the third conveying line 3 and the fourth conveying line 4 are controlled and realized by the controller according to the programming design concept. The design dimensions of the present invention are 0.84 meters high, 4.07 meters long, and 0.36 meters wide. The transmission parts are all driven by stainless steel drums and connected by synchronous belts. The four conveyor lines are powered by four motors respectively. The actions are independent of each other. The motors are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com