Terminal-cloud collaborative wind power operation and maintenance diagnosis system based on 5G

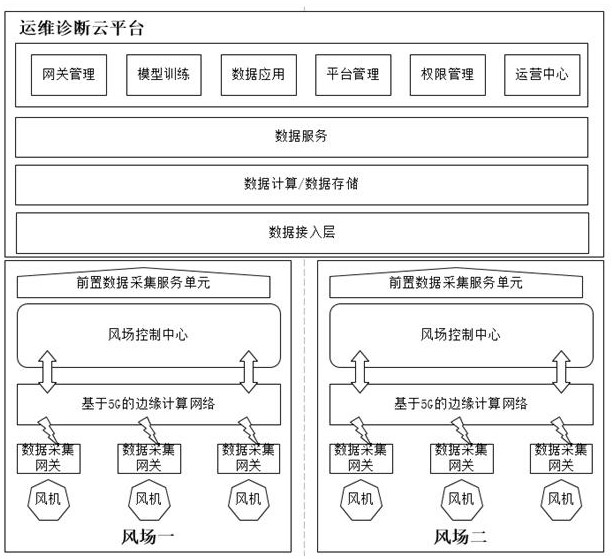

A diagnostic system, operation and maintenance technology, applied in specific environment-based services, wind turbines, monitoring of wind turbines, etc., can solve problems such as untimely equipment identification and response, low equipment troubleshooting efficiency, and inability to transmit high-definition video. Achieve the effect of enhancing multi-wind field coordination and centralized scheduling, reducing manual inspection workload, and improving data transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] Based on the terminal-cloud collaborative wind power operation and maintenance diagnosis system in Embodiment 1, the data collection gateway is deployed in the wind turbine control cabinet, and the data collection gateway and the wind turbine control cabinet correspond one-to-one.

[0048] Further, the data acquisition gateway includes a 5G communication module and a data acquisition software platform based on Linux deployment. The data acquisition period is 1S, and more than 1000 points can be collected at the same time. It supports 1920x1080p high-definition video acquisition, and data transmission is performed through the 5G communication network. Features of high bandwidth, low delay, and high guarantee, equipped with fault diagnosis intelligent algorithm, realize wind turbine failure prediction through edge computing, and optimize wind turbine operating parameters. The Linux-based deployment data acquisition software platform adopts a micro-service architecture, whi...

Embodiment 3

[0054] Based on the terminal-cloud collaborative wind power operation and maintenance diagnosis system in Embodiment 1 or 2, the 5G-based edge computing network implements fast networking of data collection gateways through multi-access edge computing, ensuring that core data does not leave the wind farm and providing high-speed Bandwidth, low latency, high security, and near-end 5G communication network support can provide network security isolation and provide data transfer for the cloud.

Embodiment 4

[0056] Based on the terminal-cloud collaborative wind power operation and maintenance diagnosis system of Embodiment 1 or 2 or 3, the wind farm control center is distributed and deployed in each wind farm, and the wind farm control center corresponds to the wind farm one by one. During the monitoring process, electronic Kanban realizes wind farm operation status monitoring.

[0057] The wind farm control center system uses 5G base stations plus MEC to form an edge computing network that collects the operating data transmitted by the data collection gateway of all wind turbines, stores them locally, and performs local coordination and control on the wind turbines to ensure that the core data does not leave the “Park” management.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com