Yaw automatic lubrication control and early warning method and system for wind driven generator

A wind turbine and automatic lubrication technology, applied in the control of wind turbines, the monitoring of wind turbines, wind turbines, etc., can solve the problems of lubrication cycle adjustment, lack of lubrication, insufficient grease in the oil storage tank of the lubricating pump, etc., to ensure safety performance and stability, and the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

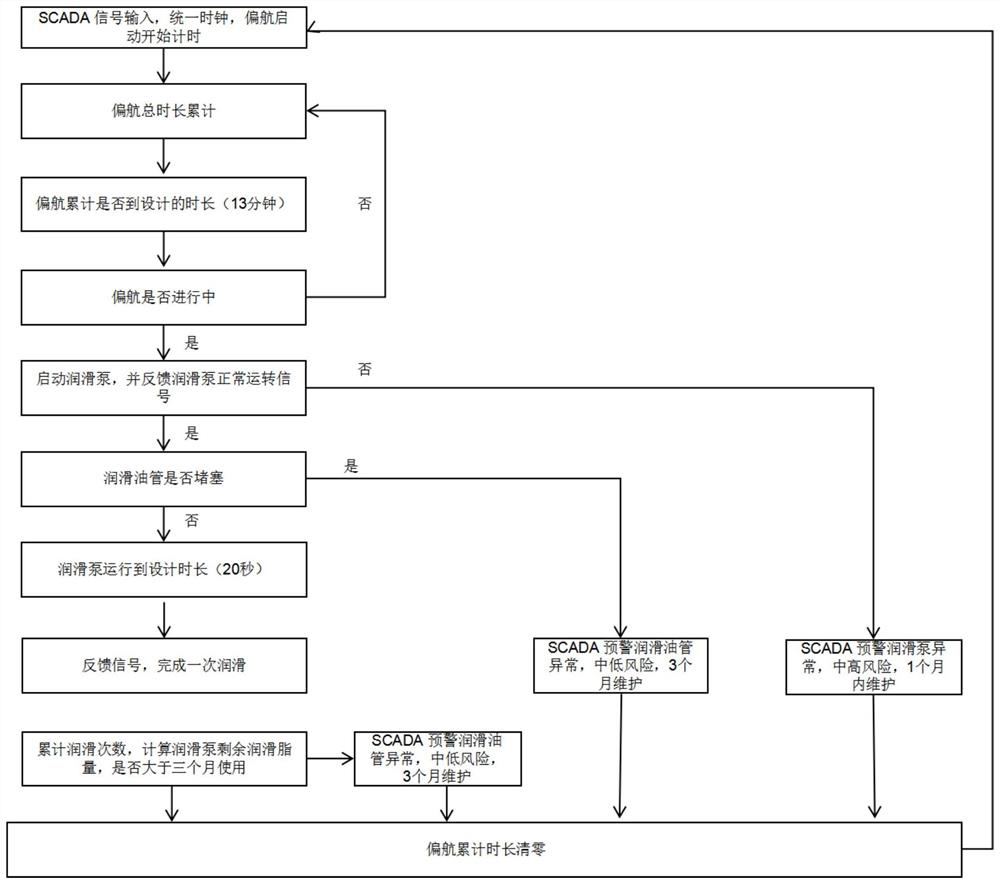

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are to explain rather than limit the present invention.

[0033] The wind turbine yaw automatic lubrication control and early warning method of the present invention comprises the following steps:

[0034] S1: Synchronize the clock of the wind turbine;

[0035] S2: Collect SCADA data and judge whether the fan is in the yaw state, if the fan is in the yaw state, the accumulated yaw start time;

[0036] S3: If the accumulated yaw start time reaches the design time, and the yaw system is still working, send a signal to start the yaw lubrication pump; if the accumulated yaw start time reaches the design time, but the yaw system is in shutdown state, the next time When the yaw is started, a signal to start the yaw lubrication pump is sent;

[0037] S4: Control the startup of the yaw lubrication pump, and record the working time of the yaw lubrication pump; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com