A kind of anti-aging agent 4020 continuous production process

A production process and anti-aging agent technology, which is applied in the continuous production process of anti-aging agent 4020, can solve the problems of affecting catalyst life and single-pass output, catalyst activation is easy to deactivate over temperature, and the consumption of methyl isobutyl ketone is large, and it is easy to achieve Disassembly and assembly, good sealing performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

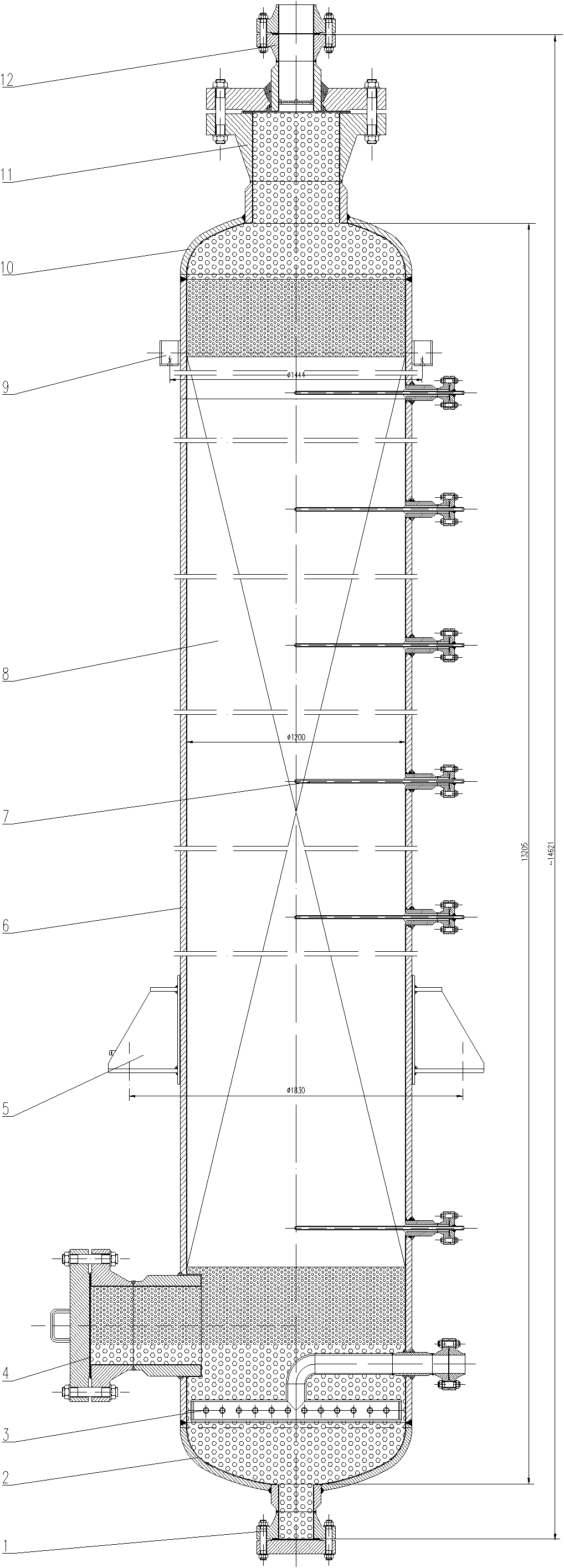

[0022] Such as figure 1 As shown, the gas-liquid-solid three-phase fixed-bed hydrogenation reactor used in the continuous production process of anti-aging agent 4020 in this embodiment includes a main container, namely a cylinder, a discharge port, a clean port, a feed pre-distributor, The upper head, the lower head, the upper support, the lower support and the temperature measuring port. The main container is a cylinder with a height of 14.6m and a diameter of 1200mm. The feed pre-distributor is a pipe-type pre-distributor. , installed in the lower part of the reactor and surrounded by ceramic balls, the nozzle of the calandria pre-distributor faces downward, the upper head is an elliptical head, the lower head is an elliptical head, and the main container is There is a manhole at the bottom of the catalyst layer, which makes it more convenient to replace the catalyst. The main body of the reactor is made of stainless steel composite plate. This reactor is used for the produc...

Embodiment 2

[0025] The gas-liquid-solid three-phase fixed-bed hydrogenation reactor used in this example is the same as that in Example 1.

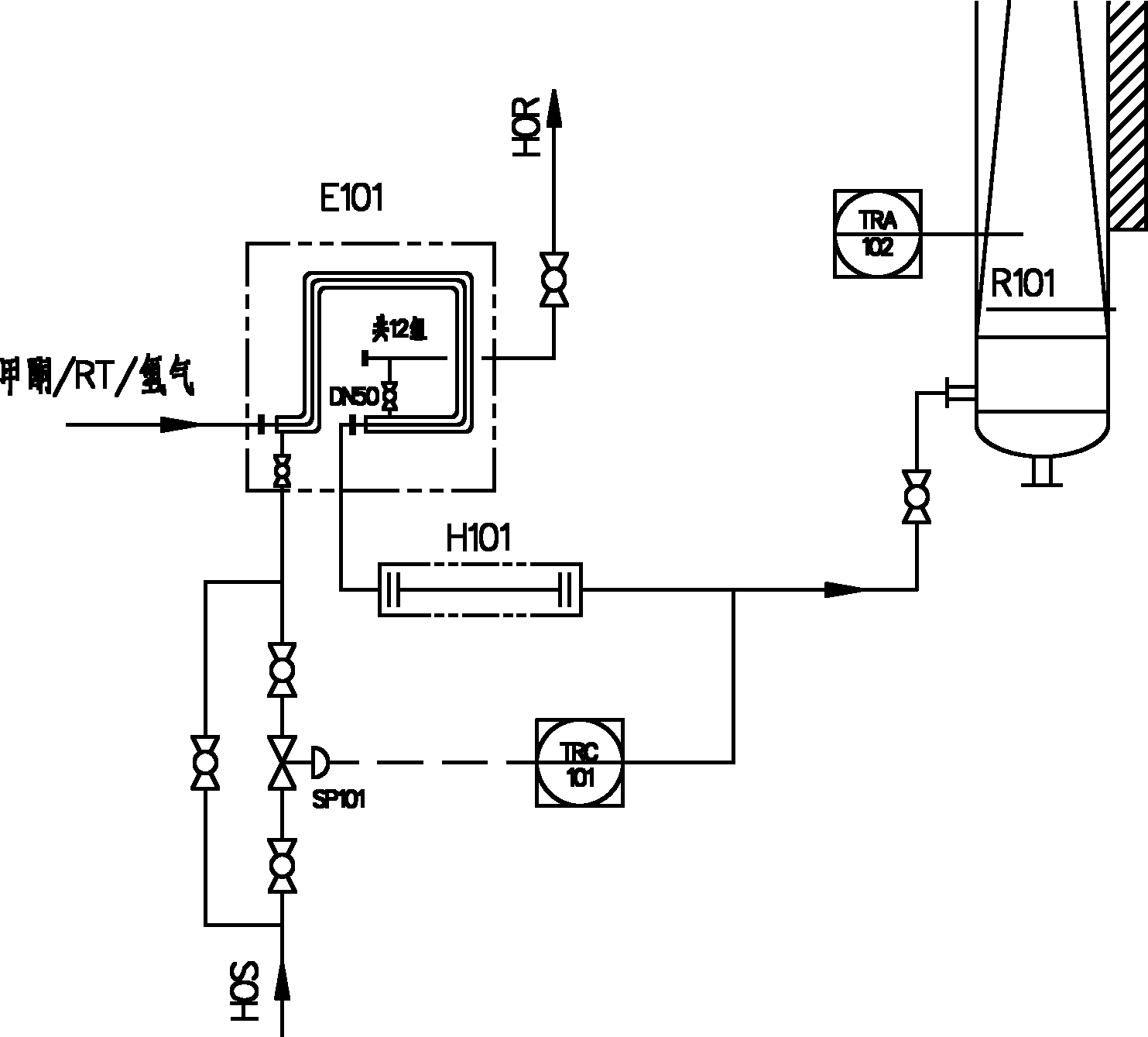

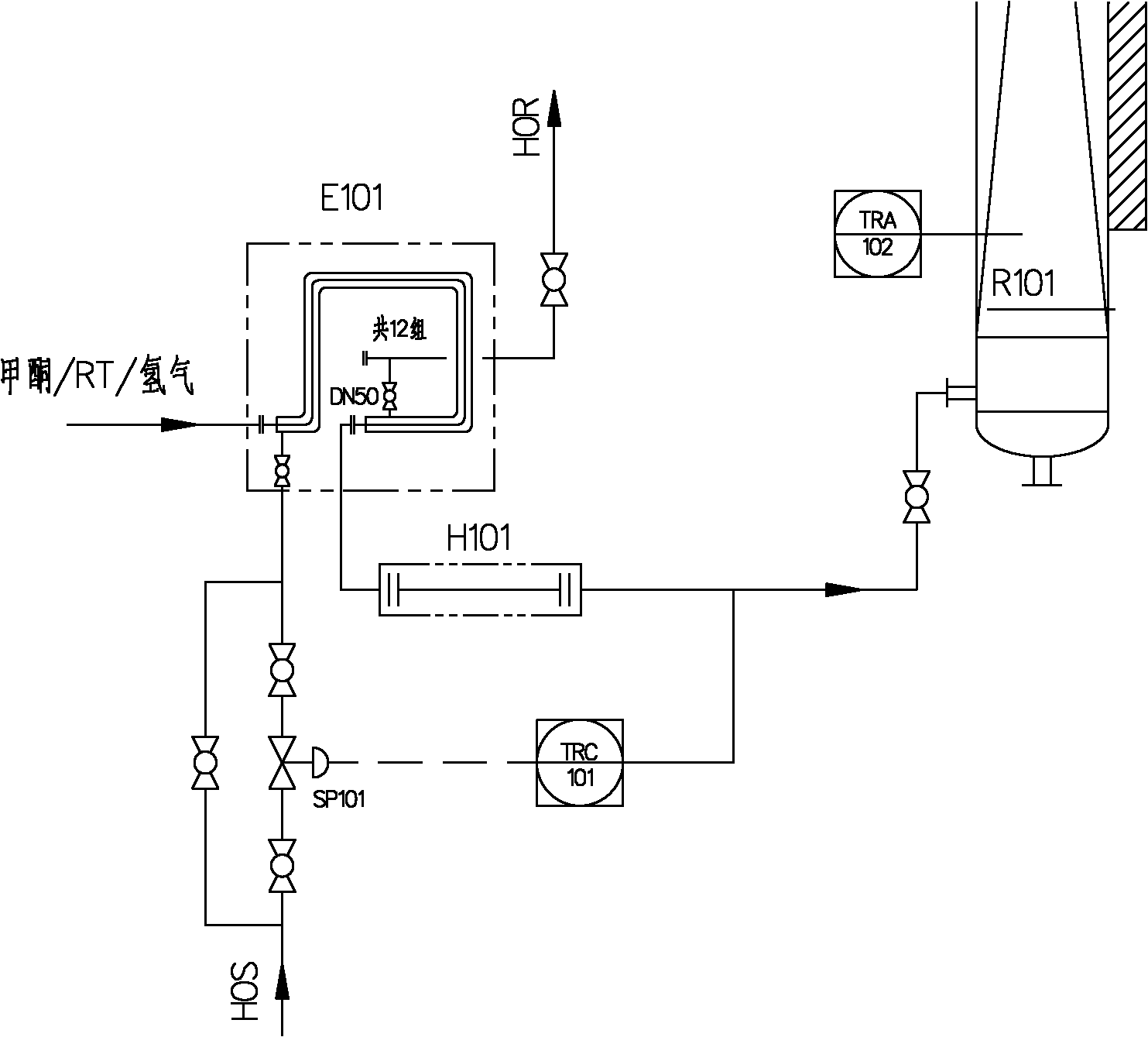

[0026] Such as figure 2 As shown, when 4020 is produced, the ratio of ketone to amine is 2:1, and the ratio of hydrogen to oil is 2000:1. The raw materials 4-aminodiphenylamine, hydrogen and methyl isobutyl ketone first enter the jacketed tube heated by heat transfer oil. The static mixer consists of a preheater E101 which is preheated to 150°C. After part of the raw materials are vaporized, they enter the static mixer H101, and then the materials enter the reactor R101 through the calandria predistributor. The liquid material fills the reactor, and hydrogen bubbles in the liquid material. Under the action of nickel catalyst, under the condition of reaction temperature of 165°C and pressure of 6MPa, it gradually reacts with the raw material, and the reacted material is discharged through the discharge port. The conversion rate can reach 95.1%.

Embodiment 3

[0028] The gas-liquid-solid three-phase fixed-bed hydrogenation reactor used in this example is the same as that in Example 1.

[0029] Such as figure 2 As shown, when 4020 is produced, the ratio of ketone to amine is 4:1, and the ratio of hydrogen to oil is 5000:1. The raw materials 4-aminodiphenylamine, hydrogen and methyl isobutyl ketone first enter the jacketed tube heated by heat transfer oil. The static mixer consists of a preheater E101 which is preheated to 220°C. After part of the raw materials are vaporized, they enter the static mixer H101, and then the materials enter the reactor R101 through the calandria predistributor. The liquid material fills the reactor, and hydrogen bubbles in the liquid material. Under the action of the nickel catalyst, the reaction temperature is 230 ° C and the pressure is 5.8 MPa, and the raw material is gradually reacted. The reacted material is discharged through the discharge port. The reaction conversion rate can reach 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com