Dual-sphere one-way metal seal ball valve

A technology of metal sealing and double spheres, which is applied in the direction of shaft sealing, valve details, valve devices, etc., can solve the problems of jamming of metal hard-sealed ball valves, external leakage of valve body and bonnet seal, internal leakage of ball valves, etc., to avoid The effect of high temperature and high pressure medium leakage, reducing manufacturing cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

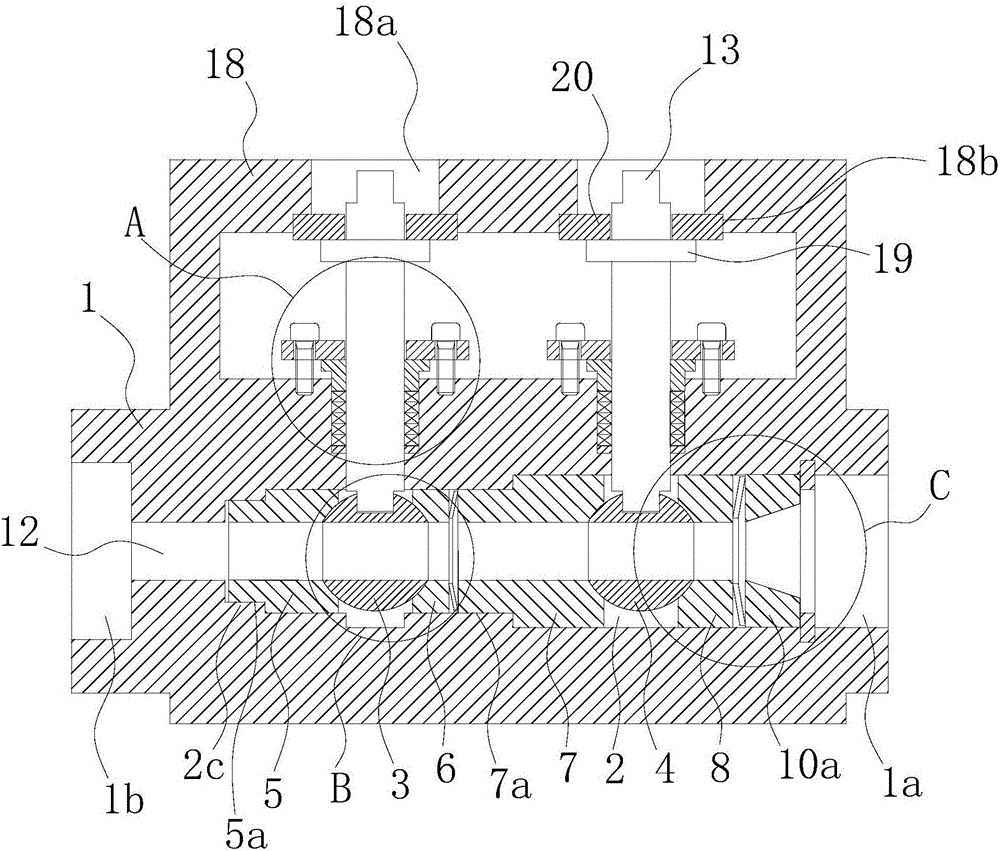

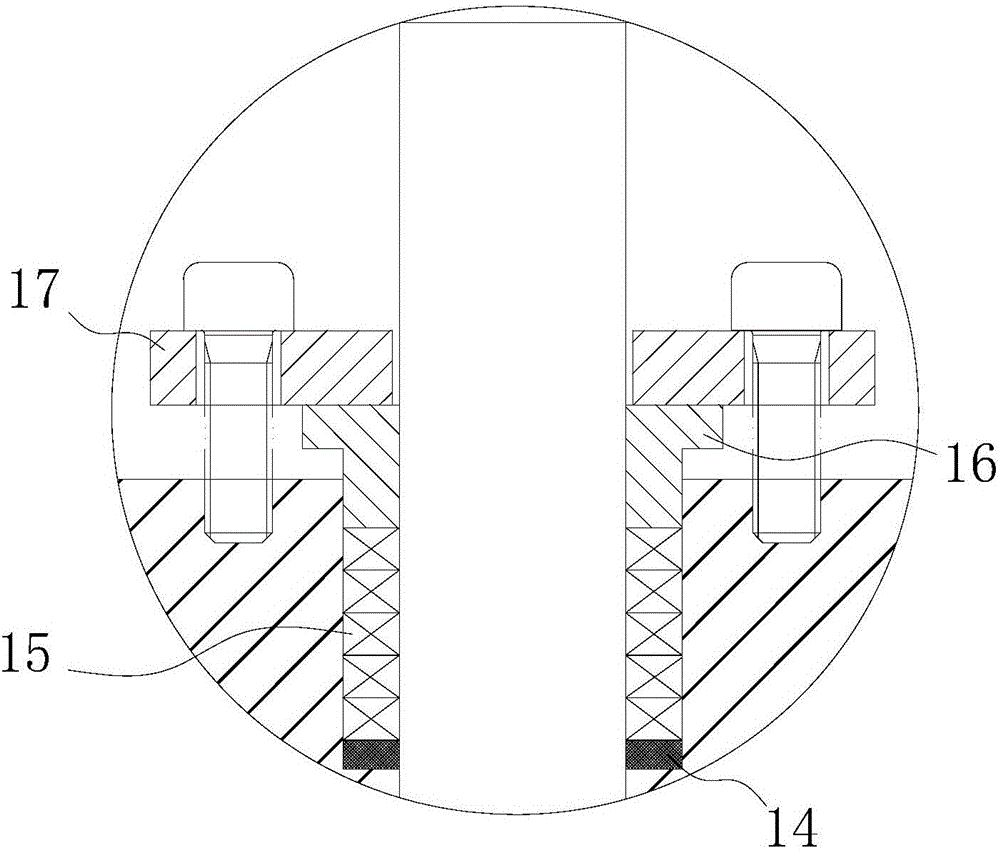

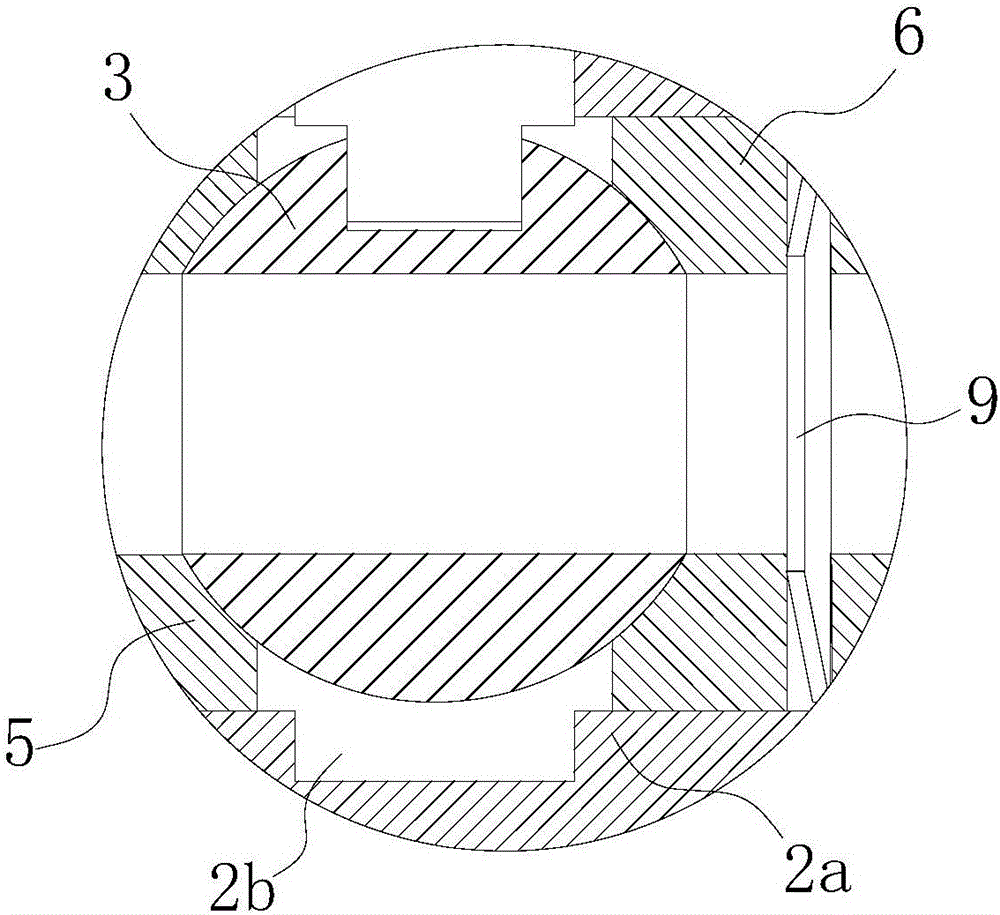

[0037] refer to Figure 1 to Figure 4As shown, a double-ball one-way metal-sealed ball valve of the present invention includes a valve body 1, a medium inlet 1a and a medium outlet 1b are respectively provided on the two ends of the valve body 1 along the axial direction, and the valve corresponding to the medium inlet 1a The body 1 is provided with a blind installation hole 2 along the axial direction, and a first valve ball 3 and a second valve ball 4 are respectively arranged in the installation blind hole 2 from the inside to the outside. A first valve seat module is provided between them, and a second valve seat module is provided between the outer wall of the second valve ball 4 and the installation blind hole 2. The first valve seat module is sandwiched by the first valve ball 3. The first fixed valve seat 5 and the first movable valve seat 6 on the outer wall are composed of the first fixed valve seat 5 and the installation blind hole 2. The interference and sealing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com