Full-automatic rubber cutter

A fully automatic, rubber-based technology, applied in forestry, application, agriculture, etc., can solve problems affecting rubber production, time-consuming, labor-intensive, and low efficiency, and achieve the effects of small resistance, expanded application range, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

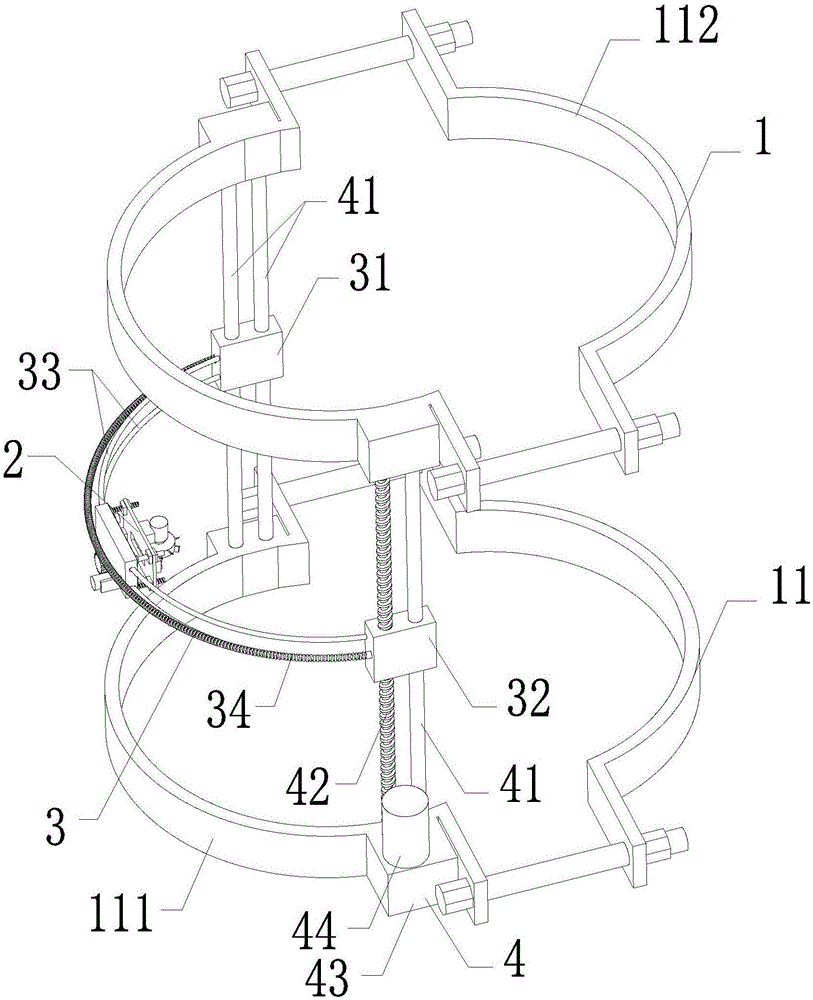

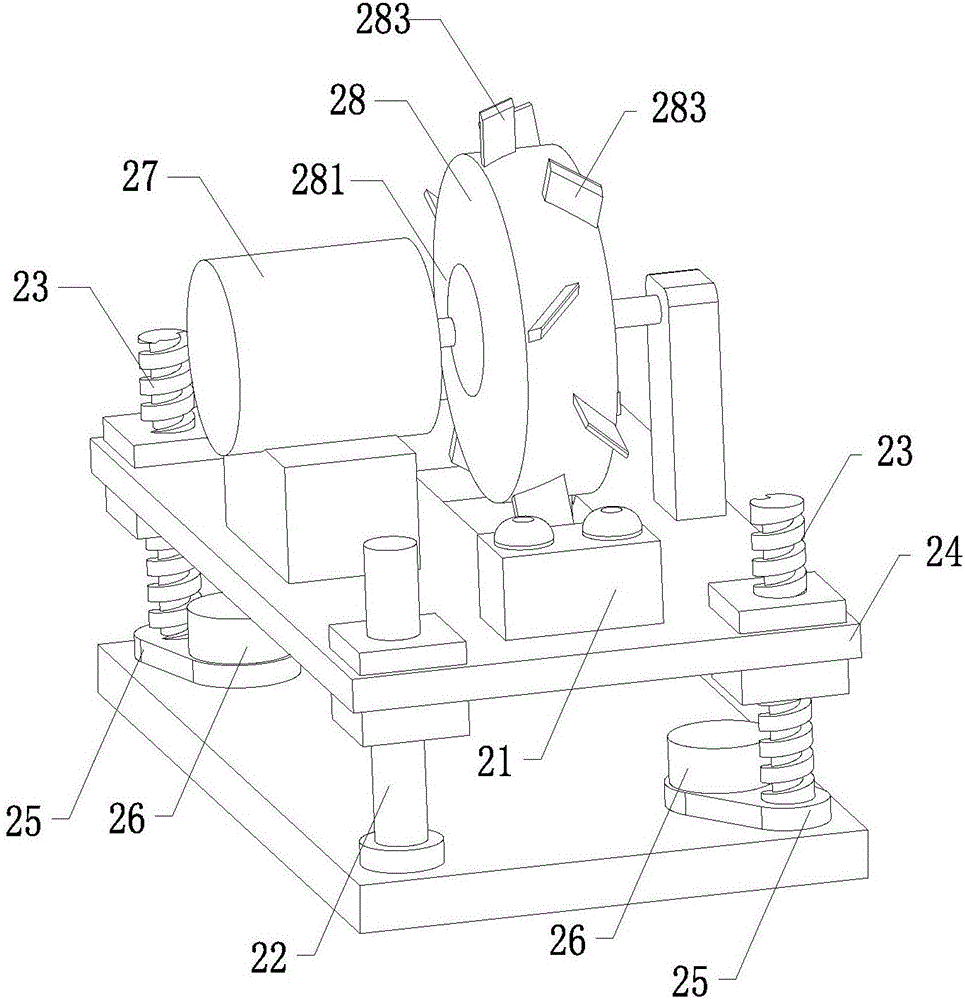

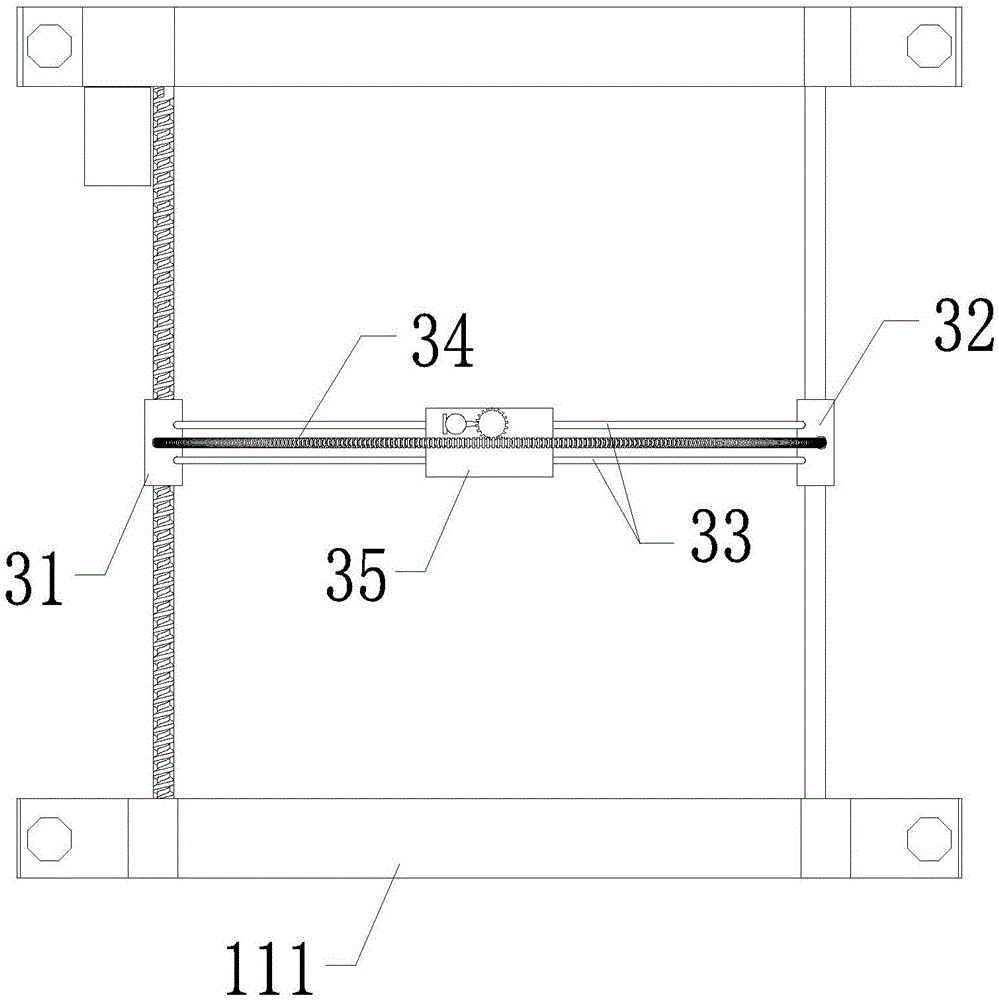

[0028] Such as figure 1 , figure 2, a kind of full-automatic rubber cutter of the present embodiment, comprises the fixing device 1 that is used to fix the device on the rubber tree, the cutting device 2 that is used to cut the rubber bark, is used to control the position of the cutting device on the horizontal plane direction The horizontal running device 3 and the vertical running device 4 for controlling the position of the cutting device in the vertical direction; the cutting device 2 is installed on the horizontal running device 3; the horizontal running device 3 is installed on the described vertical traveling device 4; the described vertical traveling device 4 is installed on the described fixing device 1.

[0029] Described fixing device 1 comprises fixed ring 11; Described fixed ring 11 has 2; Fixed ring 11 comprises fixed ring front half circle 111 and fixed ring rear half circle 112; Described fixed ring front half circle 111 and described The rear half circle 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com