Slide powder-feeding three-way reversing valve

A three-way reversing valve and sliding technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of difficult processing and maintenance of acute angle reversing two-position three-way powder reversing valves, etc. The effect of improving operation stability, improving work reliability and stability, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

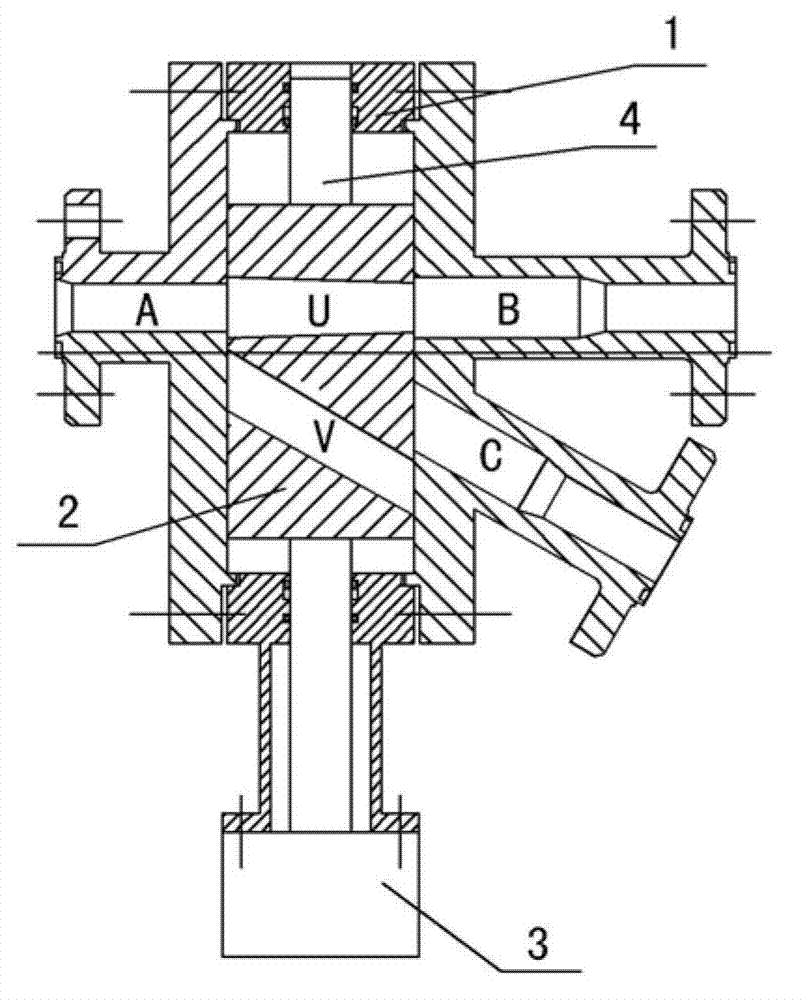

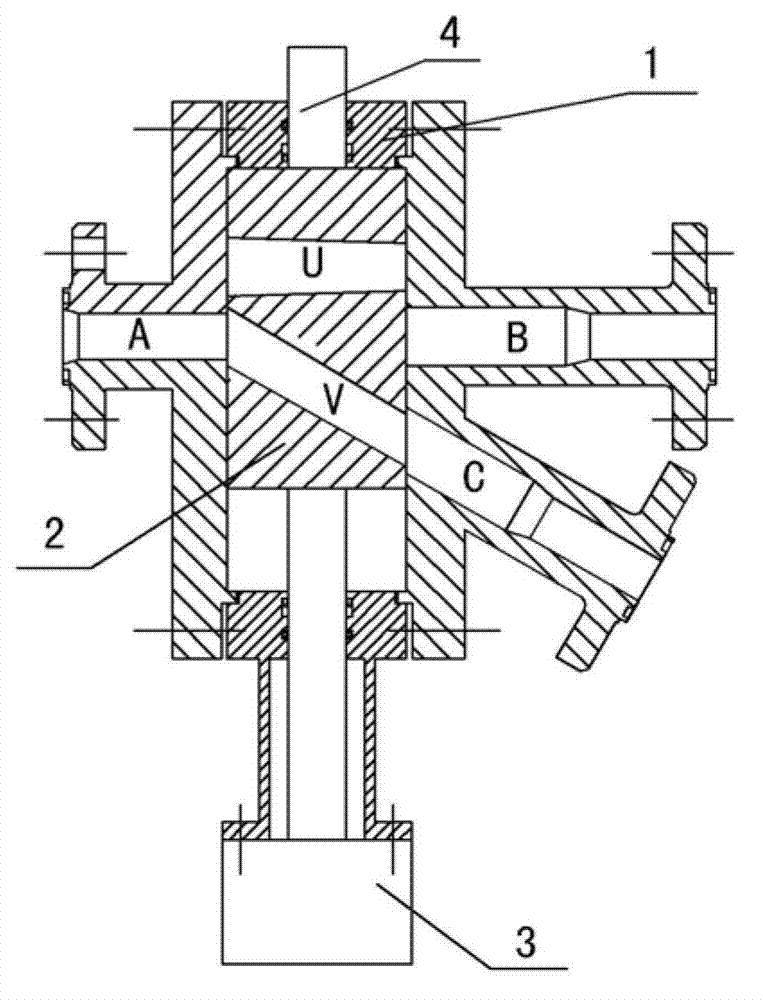

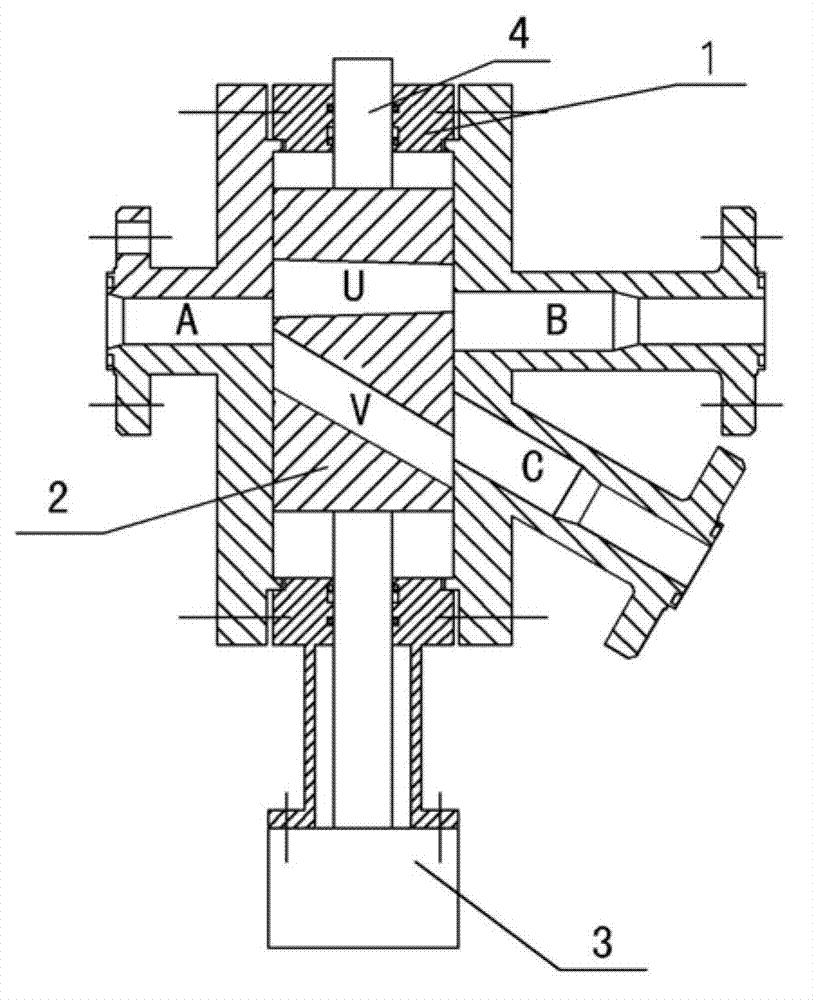

[0026] see figure 1 with Figure 4b In this embodiment, the sliding type powder feeding three-way reversing valve is provided with a columnar valve cavity in the valve body 1 of the three-way valve with one input and two outputs, and the valve located in the columnar valve cavity slides linearly along the columnar valve cavity. Double-channel cylindrical spool 2;

[0027] There are three valve body channels on the valve body 1, which are valve body inlet channel A, valve body outlet channel B and valve body outlet channel C; valve body outlet channel B is coaxial with valve body inlet channel A, and valve body outlet channel The outflow direction of B and the outlet channel C of the valve body forms an acute angle a, and the axes of the three valve body channels are on the same plane M;

[0028] The spool channel U and the spool channel V are correspondingly set in the columnar spool 2; the different positions of the linearly sliding columnar spool 2 in the columnar valve ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com