Sealing structure for electric EGR (exhaust gas recirculation) valve

A technology of EGR valve and sealing structure, which is applied in the direction of shaft seal, valve details, valve device, etc., can solve problems such as center rod sticking, achieve the effect of preventing sticking, ensuring reliability and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

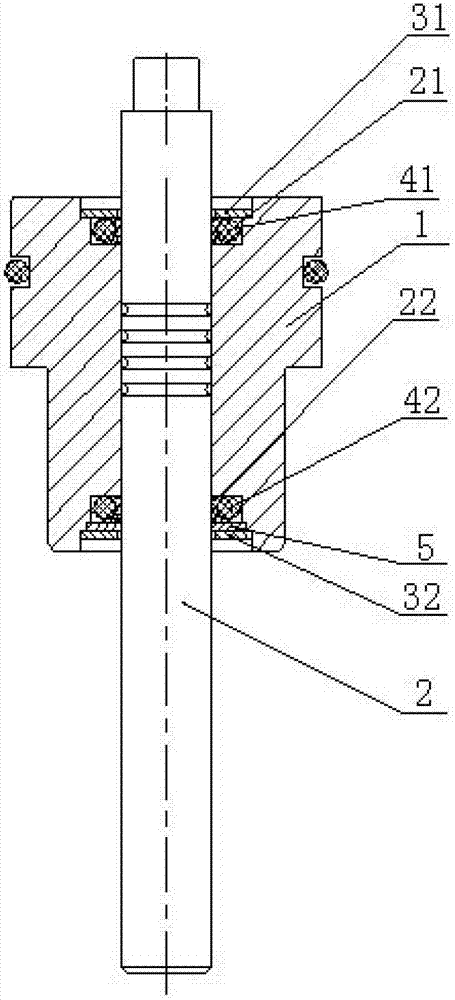

[0011] The center rod 2 of the electric EGR valve is set in the center hole of the copper sleeve 1, and the sealing structure of the electric EGR valve is as follows: figure 1 shown. The upper end of the copper sleeve is located at the position of the center hole and is provided with an upper groove, and an upper sealing device is riveted in the upper groove, and the upper sealing device includes an upper polytetrafluoroethylene sealing retaining ring 21 and an upper thin gasket 31, and the upper polytetrafluoroethylene The ethylene sealing retaining ring 21 and the upper thin gasket 31 pass through the central rod in sequence and are pressure riveted in the upper groove sequentially from bottom to top. An upper O-ring 41 is arranged inside the upper Teflon sealing ring 21, and the upper Teflon sealing ring 21 is closely matched with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com