Plastic punching frame

A punching machine and plastic technology, applied in metal processing and other directions, can solve the problems of affecting efficiency, easy to be stuck in the plastic plate or cylinder, difficult to pull out, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

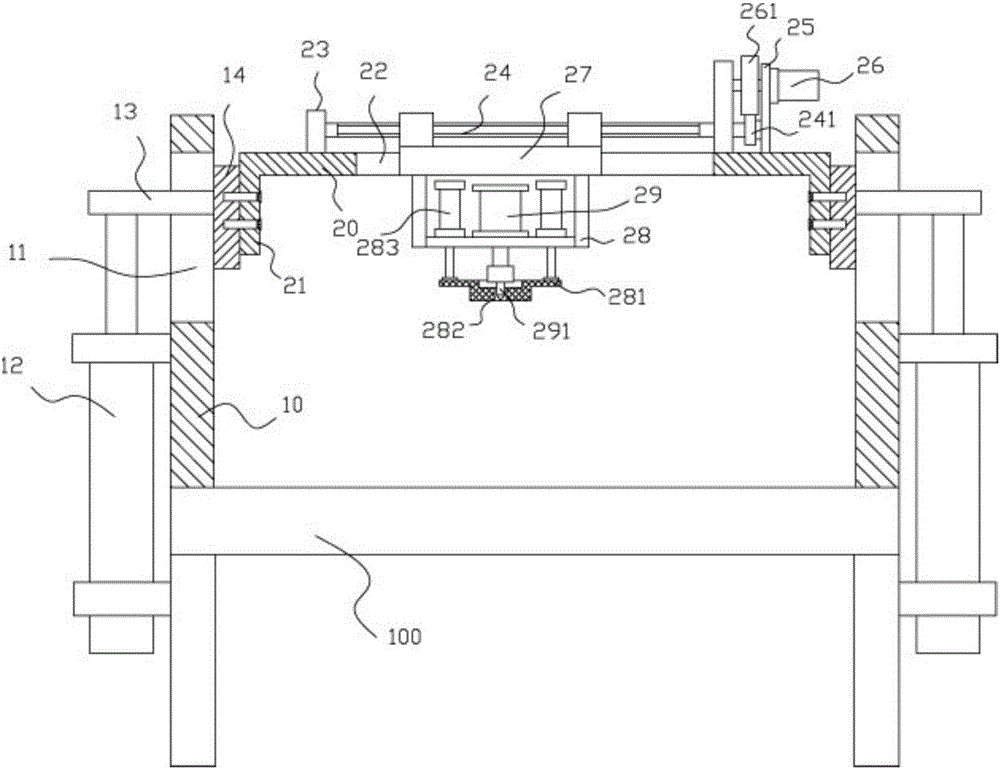

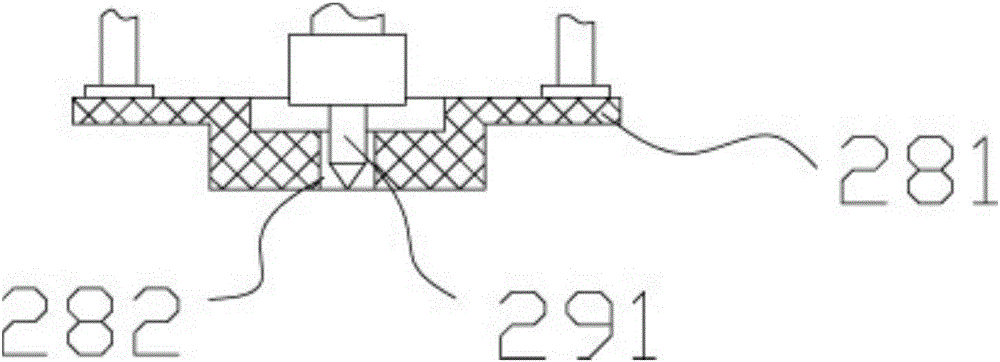

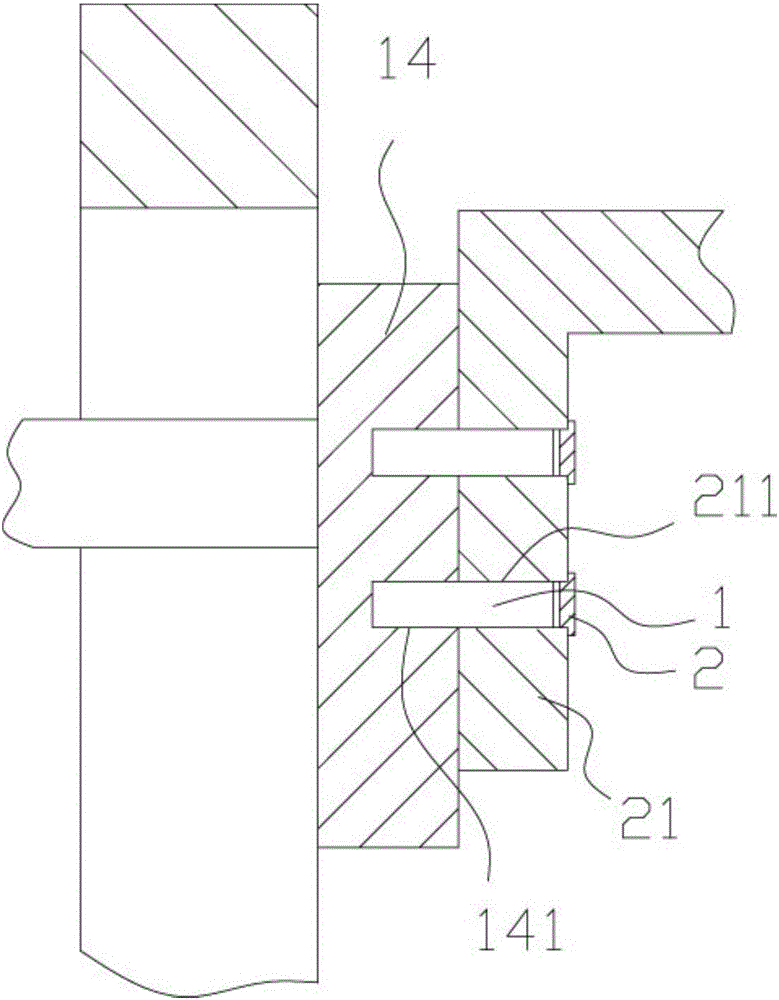

[0015] Example: see Figure 1 to Figure 3 As shown, a plastic punching frame includes a frame 100, an upper support plate 10 is fixed on both sides of the top plate of the frame 100, and the upper part of the upper support plate 10 has a vertical adjustment through groove 11. Adjusting cylinder 12 is fixed on the outer wall of support plate 10, and the end of the push rod of adjusting cylinder 12 is vertically upwards and is fixed with adjusting block 13, and adjusting block 13 is inserted and sleeved in vertically adjusting through groove 11, and on adjusting block 13 A lifting block 14 is fixed, the outer side wall of the lifting block 14 is close to the inner side wall of the upper support plate 10, the two sides of the middle transverse plate 20 have extensions 21 extending downward, and the extensions 21 are fixed on the lifting block 14;

[0016] The middle part of the middle transverse plate 20 has a transversely moving through groove 22, and the two ends of the top sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com